Oil pumping polish rod

A kind of oil sucking polished rod and surface polishing technology, applied in drill pipe, coating, metal material coating process, etc., can solve the problem of lack of fatigue resistance, achieve low fatigue resistance, meet environmental requirements, and improve corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

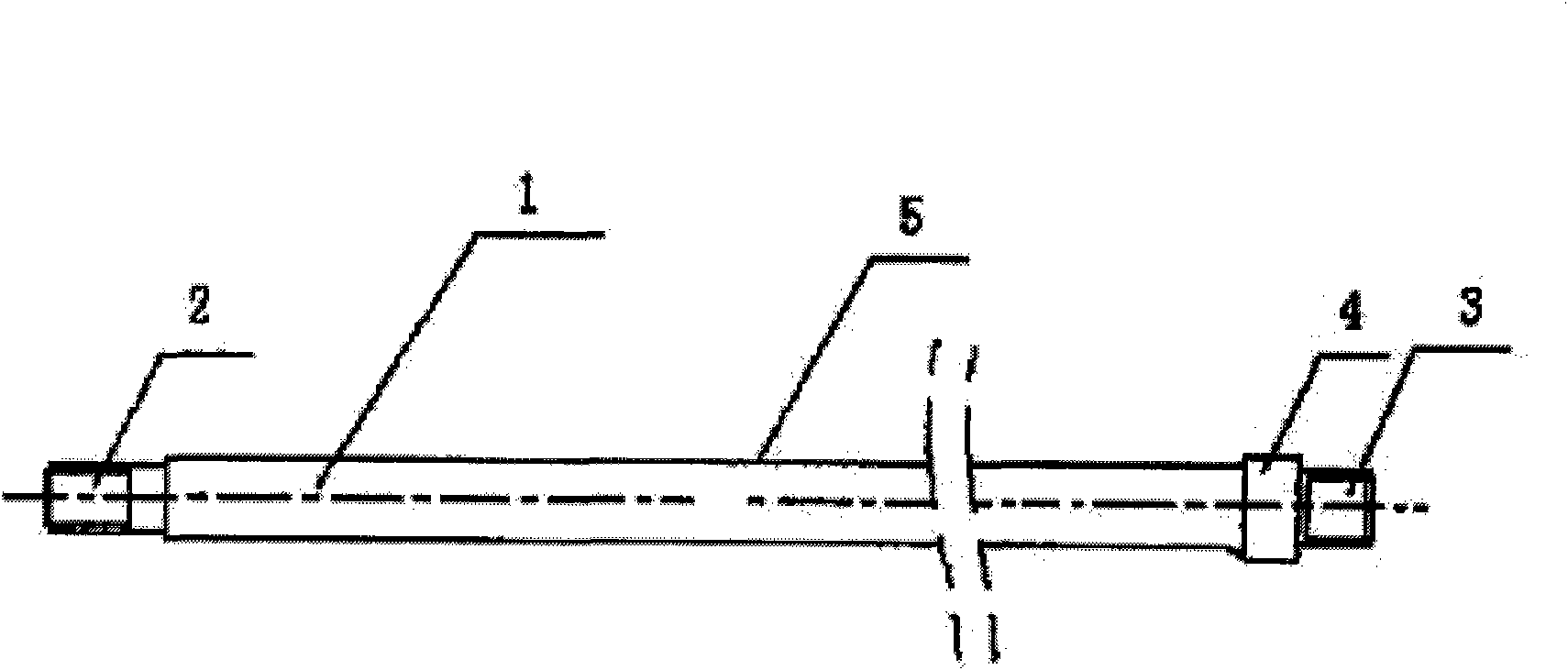

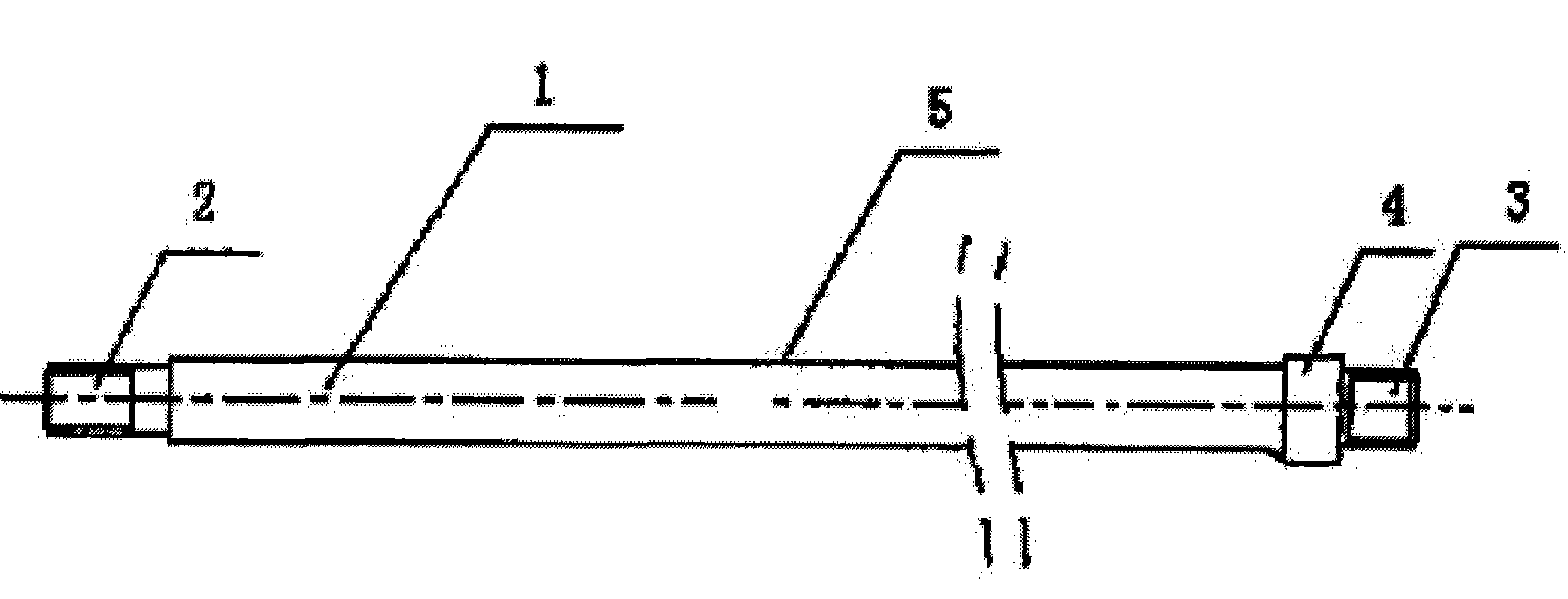

[0034] (2) Preparation of the oil sucker polished rod blank: the obtained low alloy steel bar is cold drawn to the standard length of the oil sucker polished rod of 9.14m with a cold drawing machine, and then straightened by the sucker rod straightening machine; The cylinder upsetting machine performs upsetting on one end, and then threading on both ends.

[0035] (3) Preparation of the surface coating of the oil sucker polished rod: firstly, the surface of the oil sucker polished rod base is subjected to sanding treatment to remove rust, roughen and activate the surface of the blank; A layer of nickel-based alloy coating with a thickness of 0.30mm to 0.50mm is spray-welded between the middle surface and both ends of the oil-sucking polished rod base 100mm to 800mm; after spraying, medium frequency induction heating is used for remelting to form a metallurgical bond between the coating and the base.

[0036] (4) Remelting heat treatment is performed on the nickel-based alloy c...

Embodiment 1

[0038] An oil sucker polished rod is composed of a sucker polished rod base body and a nickel-based alloy coating spray-welded on the surface of the oil sucker polished rod base body. The chemical composition and weight percentage of the base body are: carbon 0.12%, silicon 1.1%, Manganese 0.8%, phosphorus 0.022%, sulfur 0.023%, chromium 1.3%, nickel 0.25, molybdenum 0.4, and the balance is iron.

Embodiment 2

[0040] An oil-sucking polished rod, the chemical composition and weight percentage of its matrix are: carbon 0.20%, silicon 1.5%, manganese 1.0%, phosphorus 0.020%, sulfur 0.022%, chromium 0.8%, nickel 0.33, molybdenum 0.6, the balance for iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com