Production method of monocrystalline aluminum hydroxide

A technology of aluminum hydroxide and production method, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve problems such as changing high temperature Al, and achieve the effects of high hardness, low oil absorption rate and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The semen (caustic alkali Nk: 150g / L, alumina A: 170g / L) was decomposed by adding sodium oxalate at a higher temperature (85°C) under stirring conditions for 24 hours, then filtered and fully washed with hot water to obtain a filter cake Prepare the seed crystals for the next step of decomposition; add the seed crystals obtained in the first step to the semen to carry out a stirring decomposition reaction at a lower temperature (40~55°C), and filter and wash the product to obtain a single crystal aluminum hydroxide product.

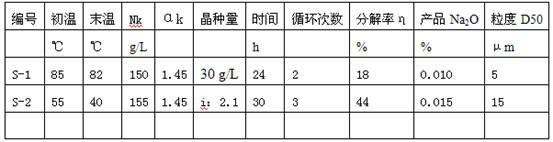

[0019] Table 1 Test parameters and results of the present invention

[0020]

Embodiment 2

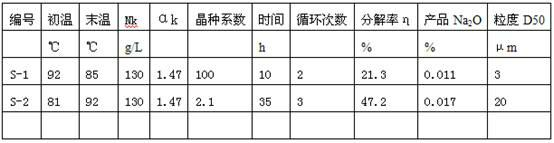

[0022] The semen (caustic alkali Nk: 130g / L, alumina A: 145g / L) was decomposed by adding sodium oxalate at a higher temperature (92°C) under stirring conditions for 10 hours, then filtered and fully washed with hot water to obtain a filter cake Prepare the seed crystals for the next step of decomposition; add the seed crystals obtained in the first step to the semen to carry out a stirring decomposition reaction at a higher temperature (81~92°C), and filter and wash the product to obtain a single crystal aluminum hydroxide product.

[0023] Table 2 Test parameters and results of the present invention

[0024]

Embodiment 3

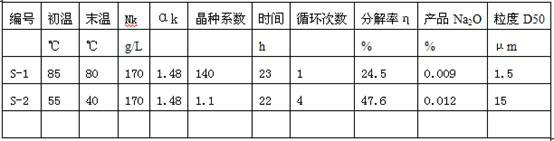

[0026] The semen (caustic alkali Nk: 170g / L, alumina A: 189g / L) was decomposed by adding sodium oxalate at a higher temperature (85°C) under stirring conditions for 23 hours, then filtered and fully washed with hot water to obtain a filter cake Prepare the seed crystals for the next step of decomposition; add the seed crystals obtained in the first step to the semen to carry out a stirring decomposition reaction at a lower temperature (40~55°C), and filter and wash the product to obtain a single crystal aluminum hydroxide product.

[0027] Test parameter and result of the present invention of table 3

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com