Polyethylene of raised temperature resistance (PE-RT) master batch and preparation method thereof

A technology of high-temperature-resistant polyethylene and color masterbatch, which is applied in the field of high-temperature-resistant polyethylene color masterbatch and its preparation, can solve the problem of high price, and achieve the effects of smooth fluidity, durable hydrostatic strength, and excellent impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]

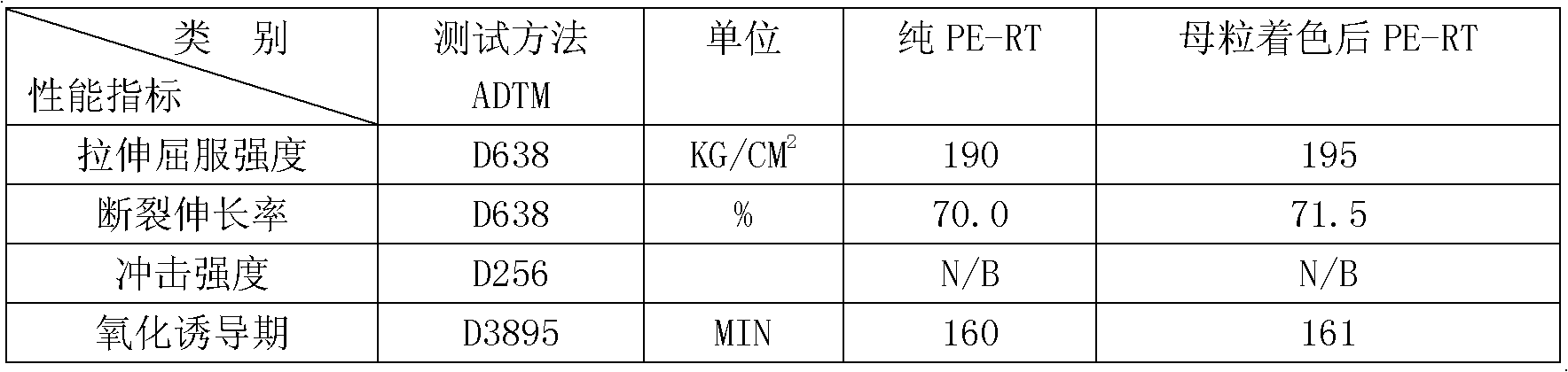

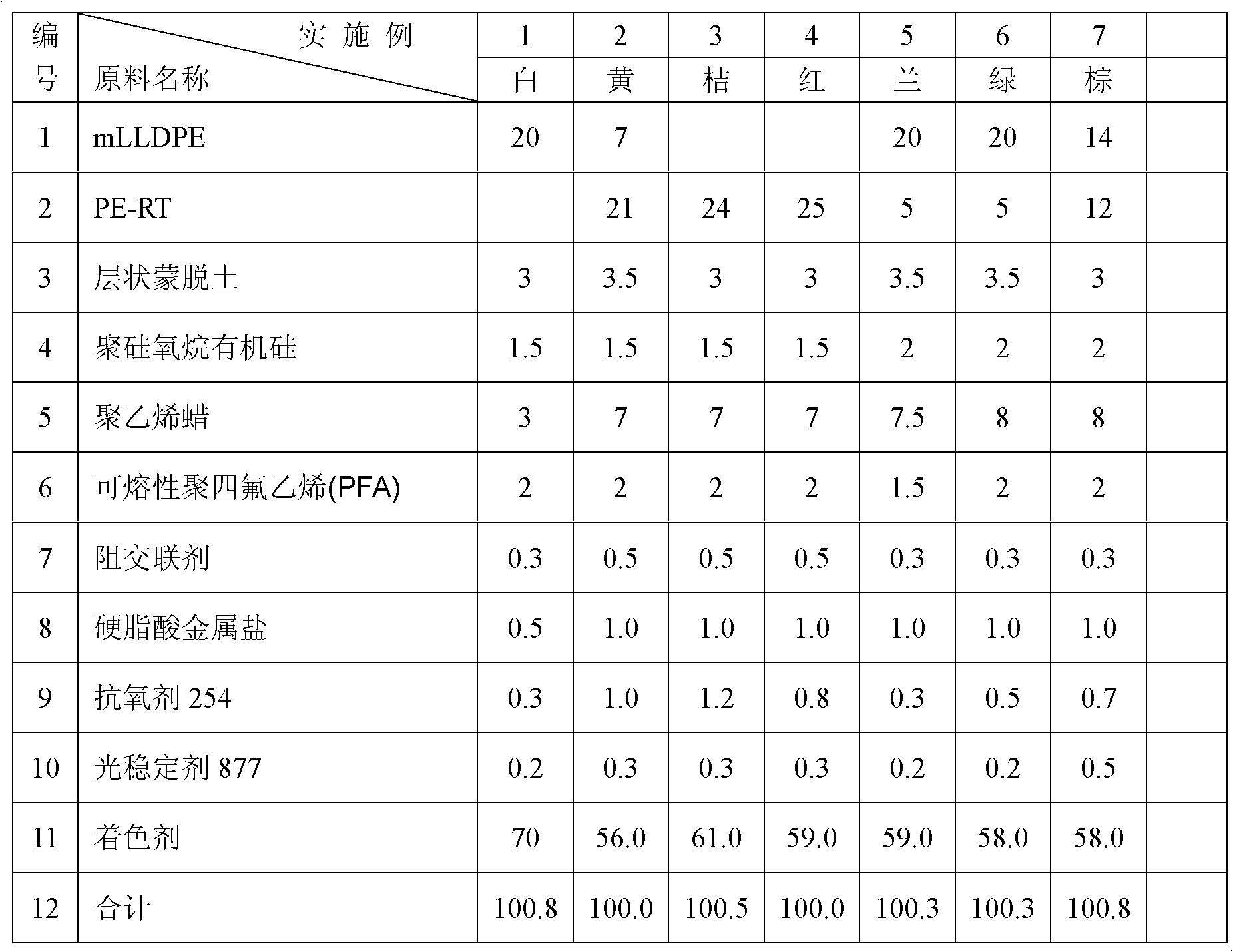

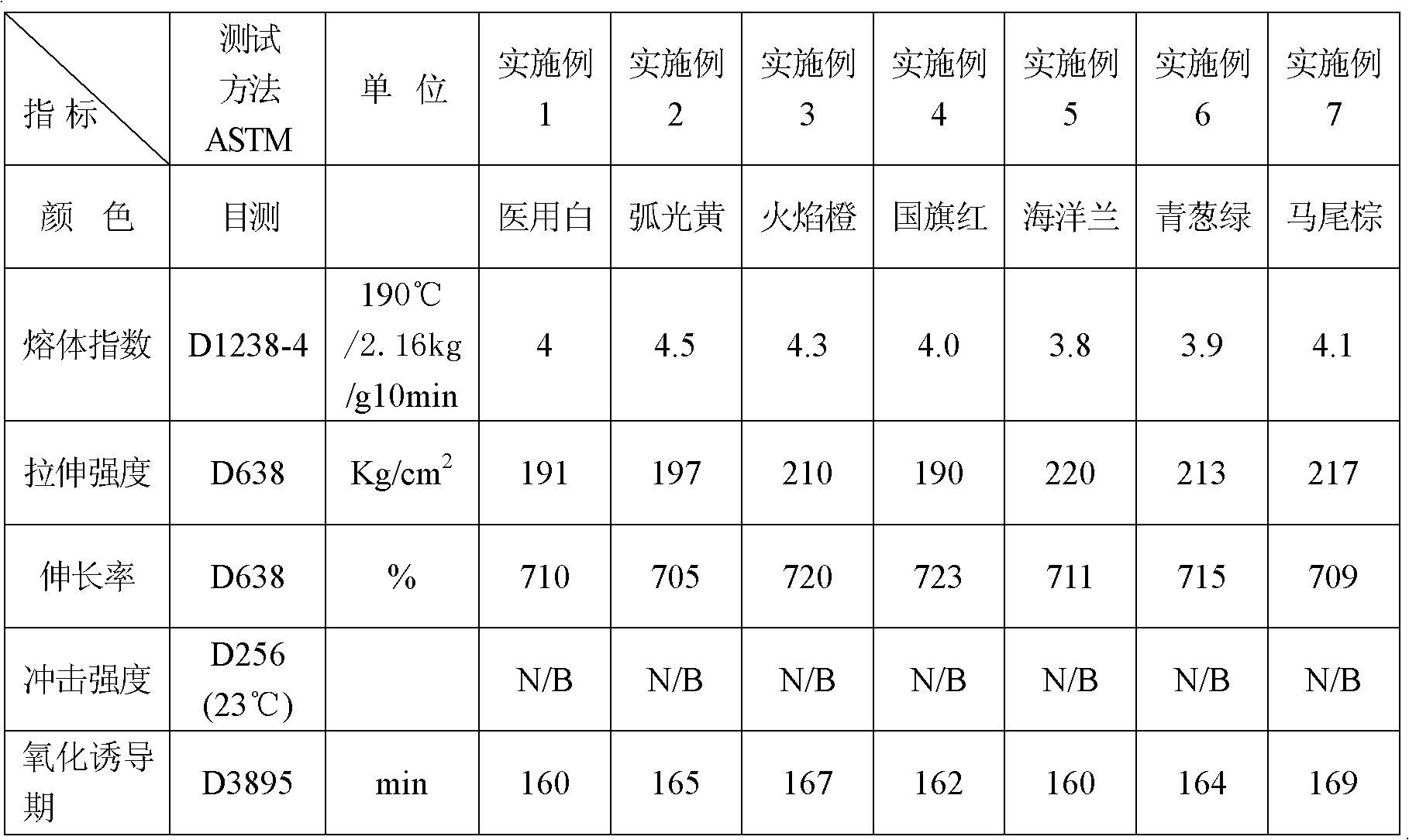

[0029] 7 embodiments of the present invention described in the table below are respectively based on rutile type titanium dioxide (1), benzimidazolone yellow (2), anthraquinone orange (3), quinaldone red (4), phthalocyanine blue (5), phthalocyanine green (6), benzimidazolone brown (7) are colorant pigments, nanoscale layered montmorillonite is used as a reinforcing agent, polyethylene wax, meltable polytetrafluoroethylene and polysilicon Oxane silicone is used as dispersion and lubricant, dimethyl sulfoxide or dimethylamine, dimethyl formamide, etc. are used as cross-linking inhibitors, and mLLDPE, PE-RT or acrylic, styrene-grafted mLLDPE is used as carrier resin , but the examples should not be construed as limiting the scope of the present invention.

[0030] The preparation steps of above-mentioned embodiment are as follows:

[0031] spare:

[0032] 1. Pull out the twin-screw extruder to combine 5 sets of shearing blocks, two in each group in parallel, replace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com