Nylon 6T composite and preparation method thereof

A composite material and nylon technology, applied in the field of good surface reinforced and toughened nylon 6T composite material and its preparation, can solve the problems of easy thermal and oxygen aging, achieve low cost, reduce the chance of migration, and improve thermal and oxygen aging resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

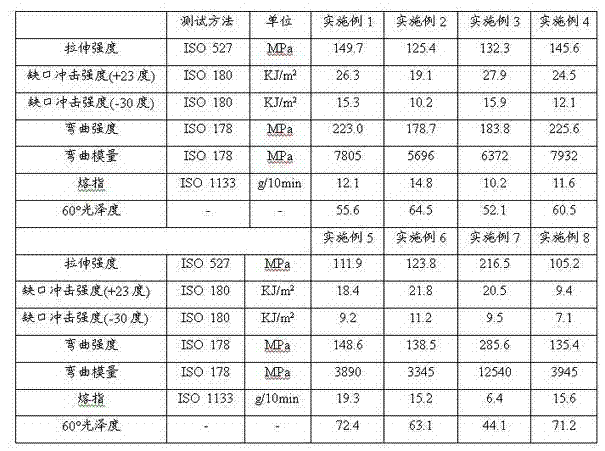

Embodiment 1

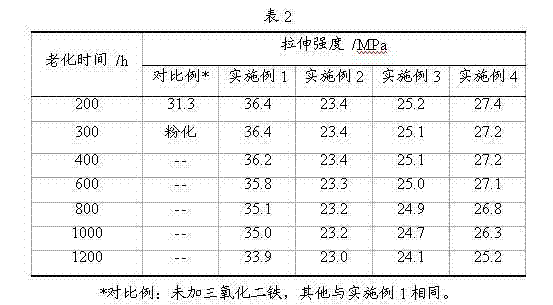

[0024] Add 58.7% nylon 6T resin, 3% ferric oxide, 7.5% maleic anhydride grafted ethylene-octene copolymer, 0.5% phenolic antioxidant and 0.3 long-chain carboxylate from the main feeding port, from 30% coated chopped glass fiber is added to the side feed port. After melting and blending in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets are injection molded into standard mechanical test specimens and swatches for testing.

Embodiment 2

[0026] Add 60.7% nylon 6T resin, 6% ferric oxide, 7.5% maleic anhydride grafted ethylene-octene copolymer, 0.5% phenolic antioxidant and 0.3% long-chain carboxylate from the main feeding port, Add 25% coated chopped glass fibers from the side feed. After melting and blending in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets are injection molded into standard mechanical test specimens and swatches for testing.

Embodiment 3

[0028] Add 48.2% nylon 6T resin, 9% ferric oxide, 12% maleic anhydride grafted ethylene-octene copolymer, 0.5% phenolic antioxidant and 0.3% long-chain carboxylate from the main feeding port, Add 30% coated chopped glass fibers from the side feed port. After melting and blending in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets are injection molded into standard mechanical test specimens and swatches for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com