Novel copper alloy and copper alloy pipe

A copper alloy, mixed rare earth technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of reduced strength, increased cracking, local grain growth, etc. Corrosion performance, effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 smooth copper alloy tube

[0031] The raw materials for the preparation of the copper alloy tube used in the embodiment of the present invention are electrolytic copper plate, pure Sn, phosphor copper CuP14 and B, and the preparation process is the commonly used electromagnetic stirring horizontal continuous casting, three-roll planetary rolling, combined drawing, Disc stretching, annealing and other processes.

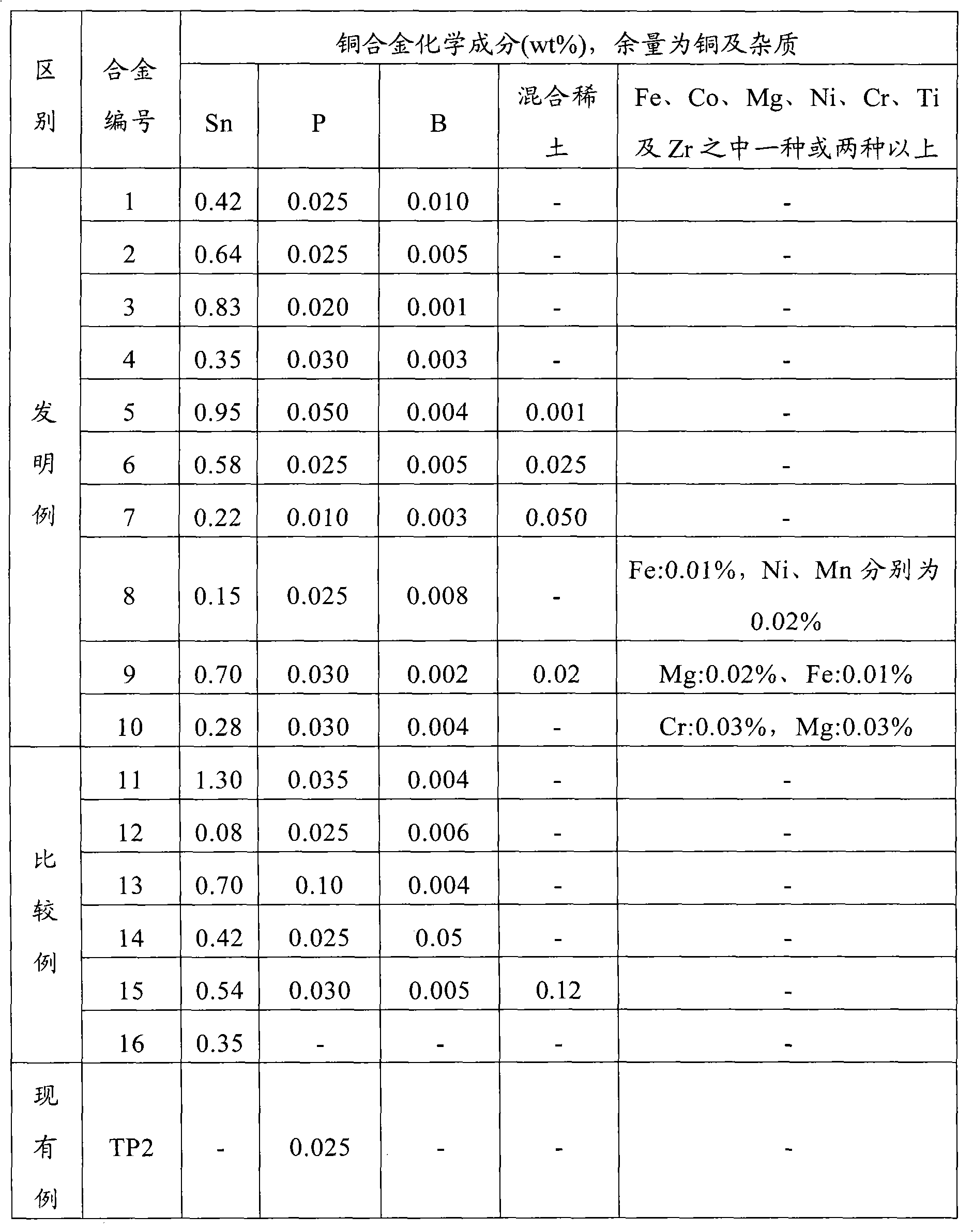

[0032] The metal composition of the copper alloy tube is shown in Table 1, containing: Sn: 0.15 to 0.95% by mass, P: 0.01 to 0.06% by mass, B: 0.001 to 0.01% by mass, and the balance is copper and unavoidable impurities. It is less than 0.06% by mass, and the radial grain size is 0.01-0.03mm. The copper alloy may further contain misch metal: 0.001 to 0.05% by mass.

[0033] The specific operation is as follows: put the graphite sheet into the bottom of the cored induction furnace, then add the electrolytic copper plate, use low-power heating to r...

Embodiment 2

[0053] Embodiment 2 semi-hard copper alloy tube

[0054] The processing technology of the semi-hard copper alloy tube in this embodiment is basically the same as that of the above-mentioned smooth copper alloy tube. However, in order to make the size of the semi-hard copper alloy tube and the smooth copper alloy tube consistent, the specification of the copper coil tube made by repeated stretching is 6.03×0.5mm, and then empty-draw the annealed copper coil through the forging die at a processing rate of 5%, and draw it to a specification of 6×0.5mm semi-hard copper alloy tube.

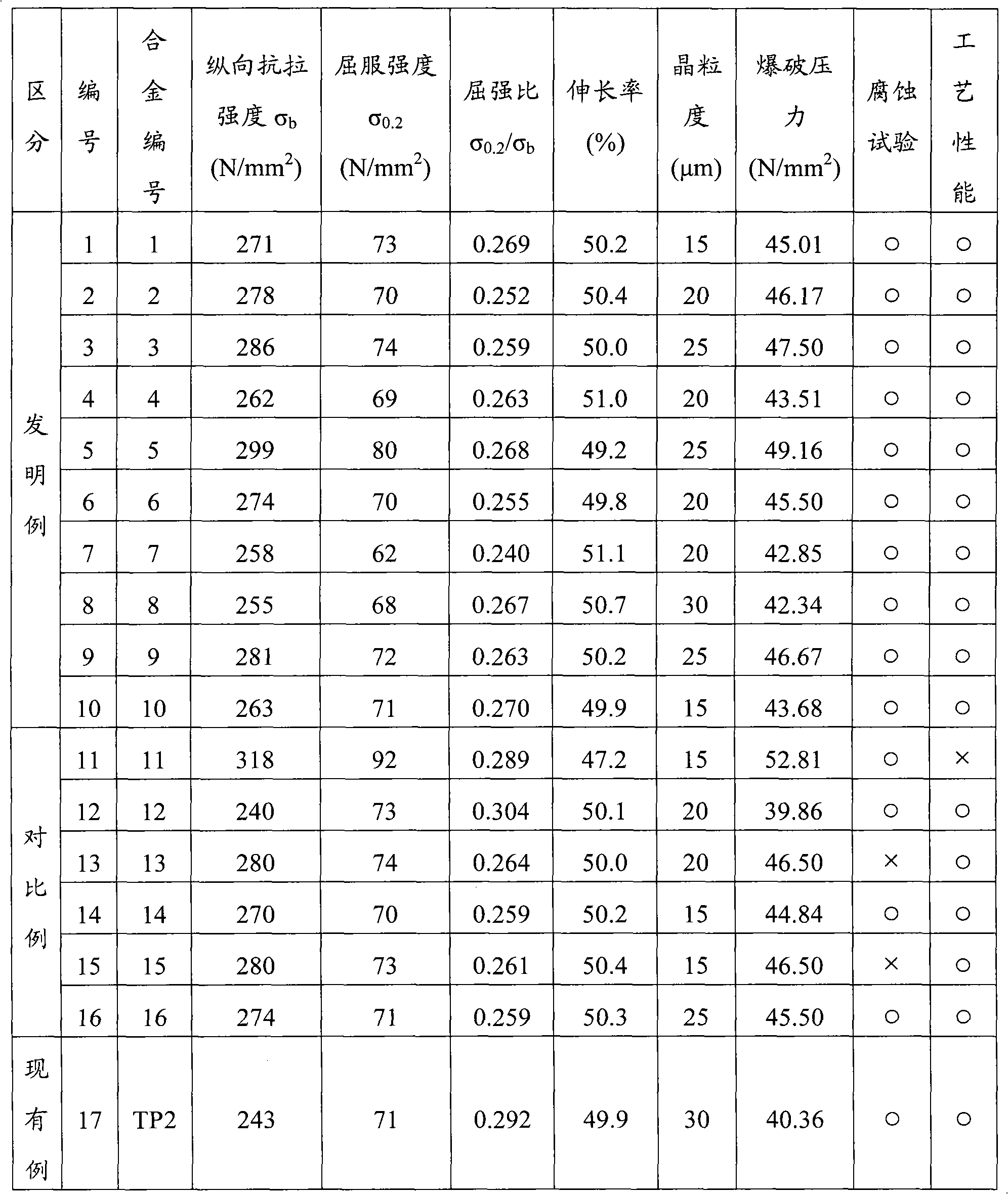

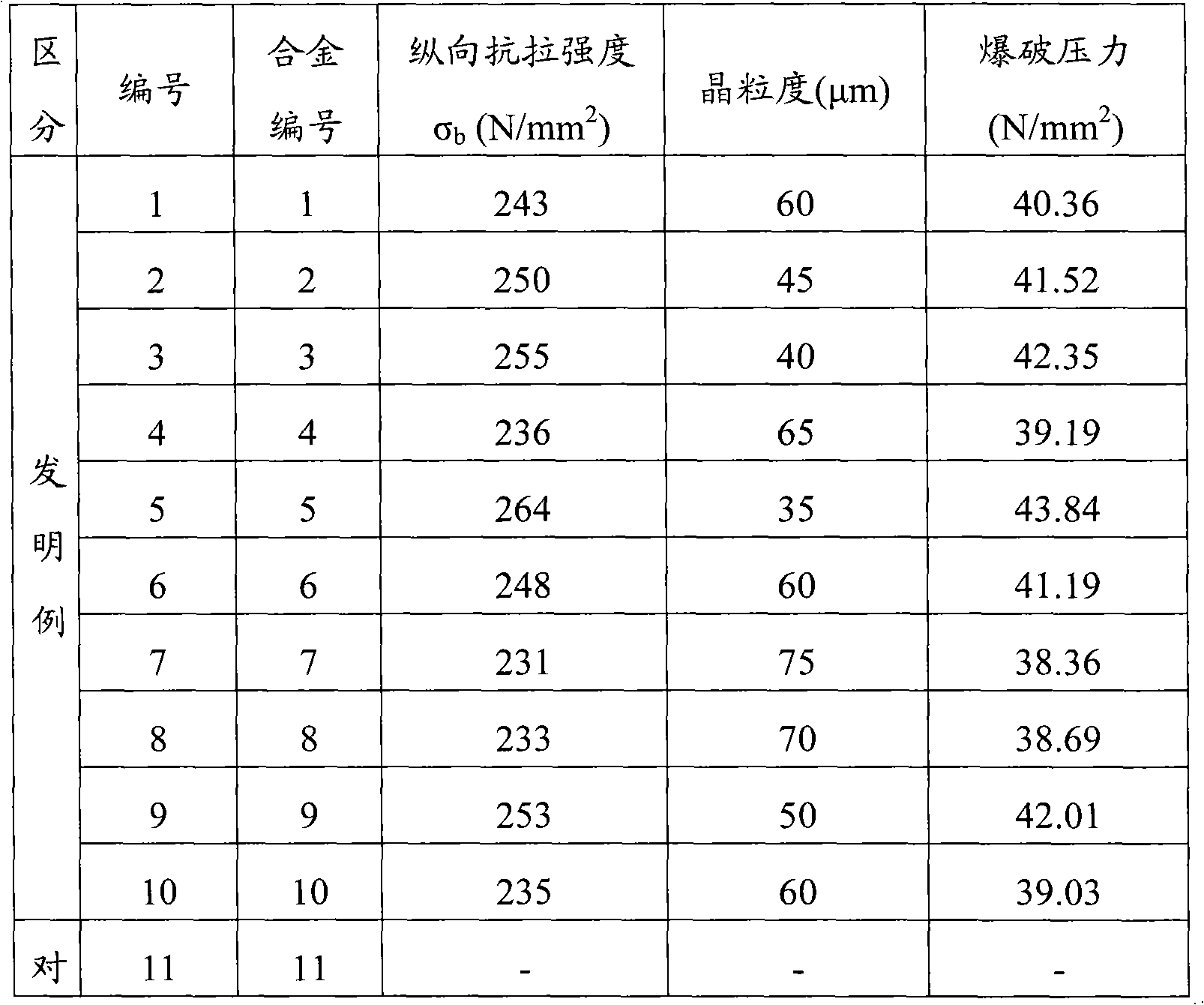

[0055] This example The properties of the 6×0.5 mm semi-hard copper alloy tube are shown in Table 4, and the following Table 5 shows the properties of the semi-hard copper alloy tube heated to 850° C.×15 s.

[0056] The performance of table 4 semi-hard copper alloy pipe

[0057]

[0058] Note: ○ indicates that the copper alloy has excellent corrosion resistance or process performance; × indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com