Method for multi-effect evaporation and dehydration of solid material

A solid material, multi-effect evaporation technology, applied in the direction of multi-effect evaporation, drying of solid materials, solid fuel, etc., can solve the problems of complicated installation, high consumption of raw steam, and complicated installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

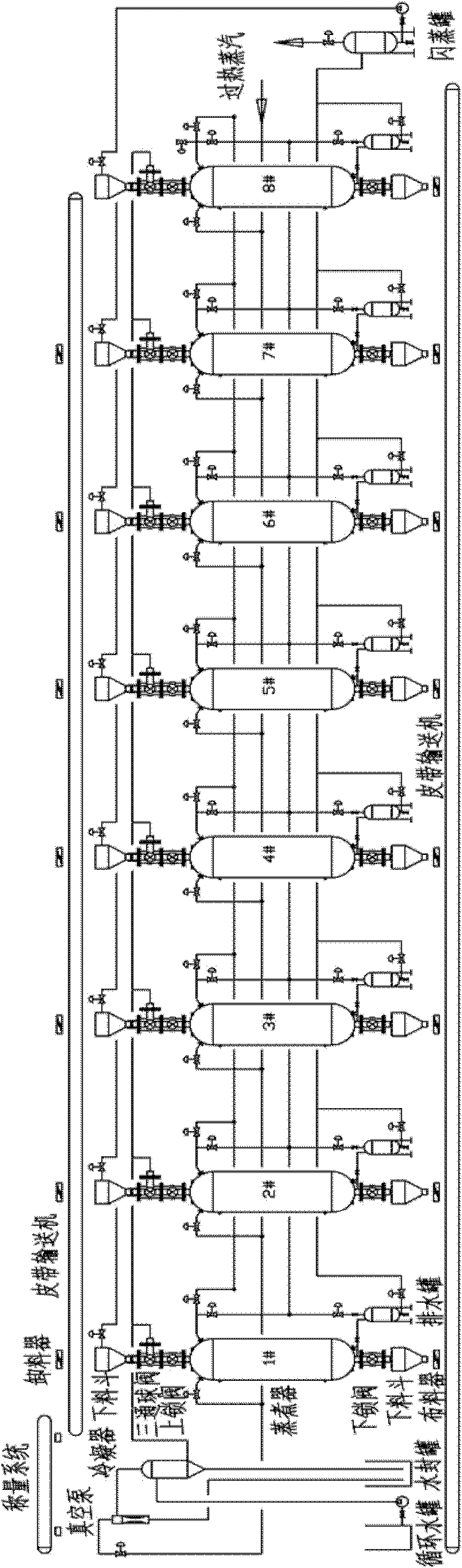

[0045] The steps for each digester are as follows figure 1 As shown, 8 digesters are provided, numbered 1-8 respectively, and the water-containing lignite passes through the weighing system, unloader and belt conveyor in sequence, from the lower hopper at the top of each digester, the three-way ball valve and the lock valve Enter these 8 digesters respectively, and each digester repeatedly executes the steps i-viii described in this article according to the order of time, and at any moment, the operations performed by each digester are as follows: digester 1 carries out In step i, the digester 2 performs step ii, ... and so on..., the digester 8 performs step viii without vacuumizing. Wherein, the saturated steam discharged from the digester 5 is used as the saturated steam of the digester 4, and the third steam discharged from the digester 6 is used as the second steam in the digester 3 until equal pressure is reached between the two digesters. The fourth steam discharged fr...

Embodiment 2

[0050] The layout of each boiler is according to figure 1As shown, but nine digesters are provided, numbered 1-9 respectively, and the lignite containing water enters these nine digesters respectively, and each digester is repeatedly performing steps i-ix described herein according to the sequence of time, And at any given moment, the operations performed by each digester are as follows: digester 1 performs step i, digester 2 performs step ii, ... and so on ..., digester 8 performs step viii, digester 9 performs step iv. Wherein, the saturated steam discharged from the digester 5 is used as the saturated steam of the digester 4, and the third steam discharged from the digester 6 is used as the second steam in the digester 3 until equal pressure is reached between the two digesters. The fourth steam discharged from the digester 7 is used as the first steam in the digester 2 until pressure equalization is achieved between the two digesters. Wherein step vi is carried out for 2...

Embodiment 3

[0054] The layout of each boiler is according to figure 1 As shown, but nine digesters are provided, numbered 1-9 respectively, and the lignite containing water enters these nine digesters respectively, and each digester is repeatedly performing steps i-ix described herein according to the sequence of time, And at any given moment, the operations performed by each digester are as follows: digester 1 performs step i, digester 2 performs step ii, ... and so on ..., digester 8 performs step viii, digester 9 performs step iv. Wherein, the saturated steam discharged from the digester 5 is used as the saturated steam of the digester 4, and the third steam discharged from the digester 6 is used as the second steam in the digester 3 until equal pressure is reached between the two digesters. The fourth steam discharged from the digester 7 is used as the first steam in the digester 2 until pressure equalization is achieved between the two digesters. Wherein step vi is carried out for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com