Flyback converter leakage inductance absorption and soft switching control

A technology of flyback converter and flyback transformer, which is applied in the direction of control/regulation system, conversion equipment with intermediate conversion to AC, conversion of DC power input to DC power output, etc. Increased system operating frequency, large switching losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

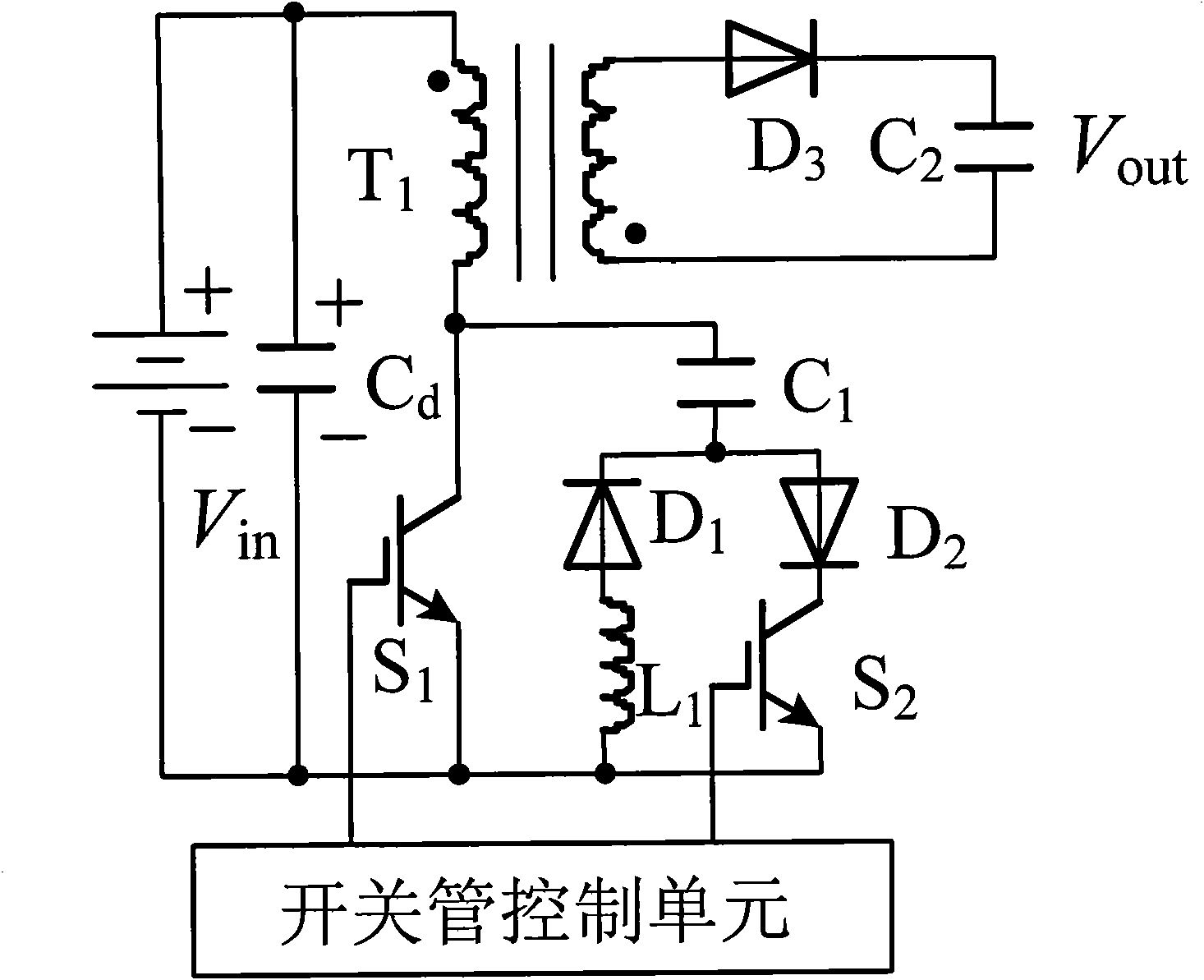

[0017] The leakage inductance absorbing circuit of the flyback converter is composed of a flyback converter and a leakage inductance absorbing circuit, and the flyback converter includes a flyback transformer T 1 , switch tube S 1 , Diode D 3 and filter capacitor C 2 , flyback transformer T 1 The same-named terminal of the primary side is connected to the positive terminal of the input power supply, and the non-identical terminal of the primary side is connected to the switch tube S 1 Drain, switch tube S 1 The source is connected to the negative terminal of the power supply, and the flyback transformer T 1 The non-identical end of the secondary side is connected to the diode D 3 Anode, the terminal with the same name on the secondary side is connected to the filter capacitor C 2 One end of the diode D 3 The cathode is connected to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com