Method for producing enteric cysteamine hydrochloride coated granules

A cysteamine-coated and cysteamine hydrochloride technology is applied in the production field of enteric-coated cysteamine hydrochloride-coated particles, and can solve the problem that large-scale industrial production cannot be applied, large-scale industrial production is not easy, and disulfide is ineffective. and other problems to achieve the best absorption effect, improve bioavailability, and avoid adverse reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

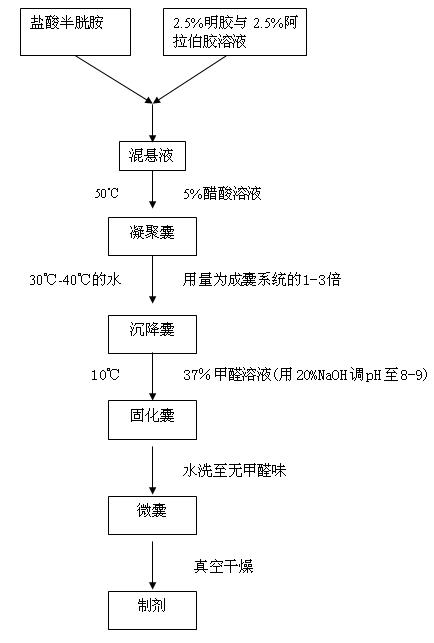

[0029] Mix and dissolve 1 part of cysteamine hydrochloride and 0.2 parts of capsule material (gelatin solution with mass concentration of 2.5% and gum arabic solution with mass concentration of 2.5%, weight ratio 1:1) to form a suspension. Add an appropriate amount of 5% acetic acid solution to the suspension, mix at 50°C, adjust the pH of the suspension to 4.0, and form coacervates. Then add 1 volume of water at 30°C to form a settling pocket. Then add 2.5 mL of formaldehyde solution with a mass concentration of 37%, mix at 10°C, and adjust the pH to 8.0 with an appropriate amount of 20% NaOH to form a solidified capsule. The obtained cured capsules are washed with water until there is no formaldehyde smell to form microcapsules. The obtained microcapsules are vacuum-dried to obtain the finished product.

Embodiment 2

[0031] Mix and dissolve 1 part of cysteamine hydrochloride and 0.3 parts of capsule material (gelatin solution with mass concentration of 4.0% and gum arabic solution with mass concentration of 4.0%, weight ratio 1:1) to form a suspension. Add an appropriate amount of 5% acetic acid solution to the suspension, mix at 50°C, adjust the pH of the suspension to 4.2, and form coacervates. Then add 2 times the volume of water at 35°C to form a settling pocket. Then add 2.5 mL of formaldehyde solution with a mass concentration of 37%, mix at 10°C, and adjust the pH to 8.5 with an appropriate amount of 20% NaOH to form a solidified capsule. The obtained cured capsules are washed with water until there is no formaldehyde smell to form microcapsules. The obtained microcapsules are vacuum-dried to obtain the finished product.

Embodiment 3

[0033] Mix and dissolve 1 part of cysteamine hydrochloride and 0.5 part of capsule material (gelatin solution with mass concentration of 5.0% and gum arabic solution with mass concentration of 5.0%, weight ratio 1:1) to form a suspension. Add an appropriate amount of 5% acetic acid solution to the suspension, mix at 50°C, adjust the pH of the suspension to 4.5, and form coacervates. Then add 3 times the volume of water at 40°C to form a sedimentation pocket. Then add 2.5 mL of formaldehyde solution with a mass concentration of 37%, mix at 10°C, and adjust the pH to 9.0 with an appropriate amount of 20% NaOH to form a solidified capsule. The obtained cured capsules are washed with water until there is no formaldehyde smell to form microcapsules. The obtained microcapsules are vacuum-dried to obtain the finished product.

[0034] Illustrate effect of the present invention below by contrast test:

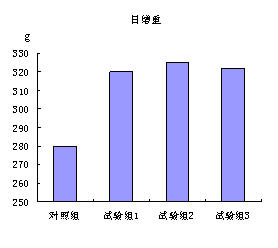

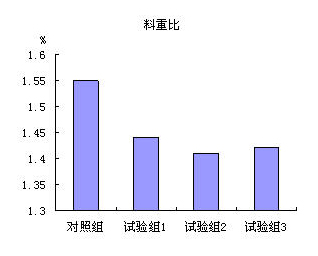

[0035] Add the cysteamine hydrochloride products (test groups 1-3) and the exis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com