Inclined pipe and clarifying/precipitating device for separating mud from water

A mud-water separation and sedimentation device technology, applied in the sedimentation tank and other directions, can solve the problems of power consumption, poor quality of sediment flocs, high technical difficulty, etc., and achieve the effect of improving efficiency and effect, increasing hydraulic load, and reducing separation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

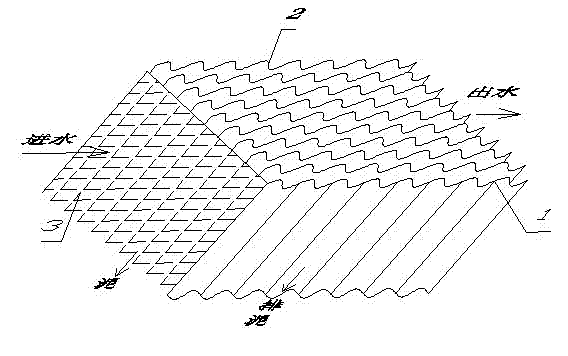

[0033] Embodiment 1: see figure 1 , the oblique pipe for mud-water separation of the present invention prepares the hexagonal honeycomb oblique pipe according to the similar prior art, suppresses the positive trapezoidal wave plate 2 of wave height 3mm, adjacent wave width (wave spacing) 200mm, directly opposite with adjacent and relative wave plate ( The troughs and crests are relatively non-staggered and opposite to each other) 35mm apart from each other and positioned adjacent to the space, and in the space according to the upper and lower intervals of 35mm, separate slant strips 3 with an inclination of 60 degrees (the trapezoidal wave plate is also inclined at 60 degrees vertically), the slant strips The lower side is in the shape of a square wave zigzag, forming an inclined tube 1 with two-way shallow separation.

Embodiment 2

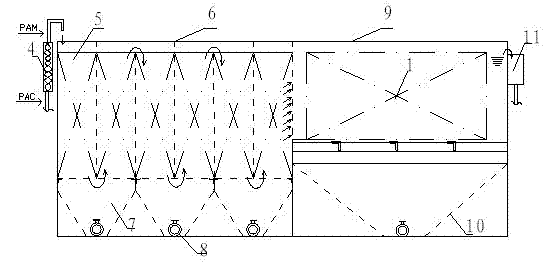

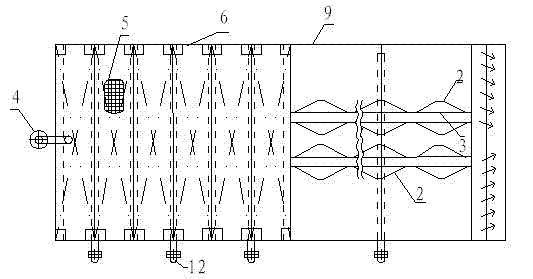

[0034] Example 2: see Figure 2-4 , The clarification or sedimentation device of the present invention consists of two parts, the front flocculation reaction zone 6 and the rear clarification zone 9 according to the flow process, and the depth of the pool is 3.8m. The flocculation reaction zone 6 is adjacently divided into three reaction zones with approximately equal volumes. At the bottom of each flocculation reaction zone, there is a triangular mud collecting bucket 7, a built-in mud discharge pipe 8 (gravity mud discharge), and a mud discharge valve 12 outside. Each area is separated by a partition to form a water turn-back flow. A flocculation reaction grid is arranged on a metal frame with φ10mm nylon ropes 14 and 15 orthogonally woven into a square grid with a hole edge of 55*55mm. 5. The height of each single-layer grid 13 is 10mm. The upper and lower spacing of each layer grid in the first reaction zone is 80mm, the upper and lower spacing of each layer grid in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com