Recycling method of residual liquor in production of trichloroethylene

A technology for trichlorethylene and recovery methods, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of low recovery rate, high recovery cost, and more waste water, so as to improve product yield, The effect of high recycling rate and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

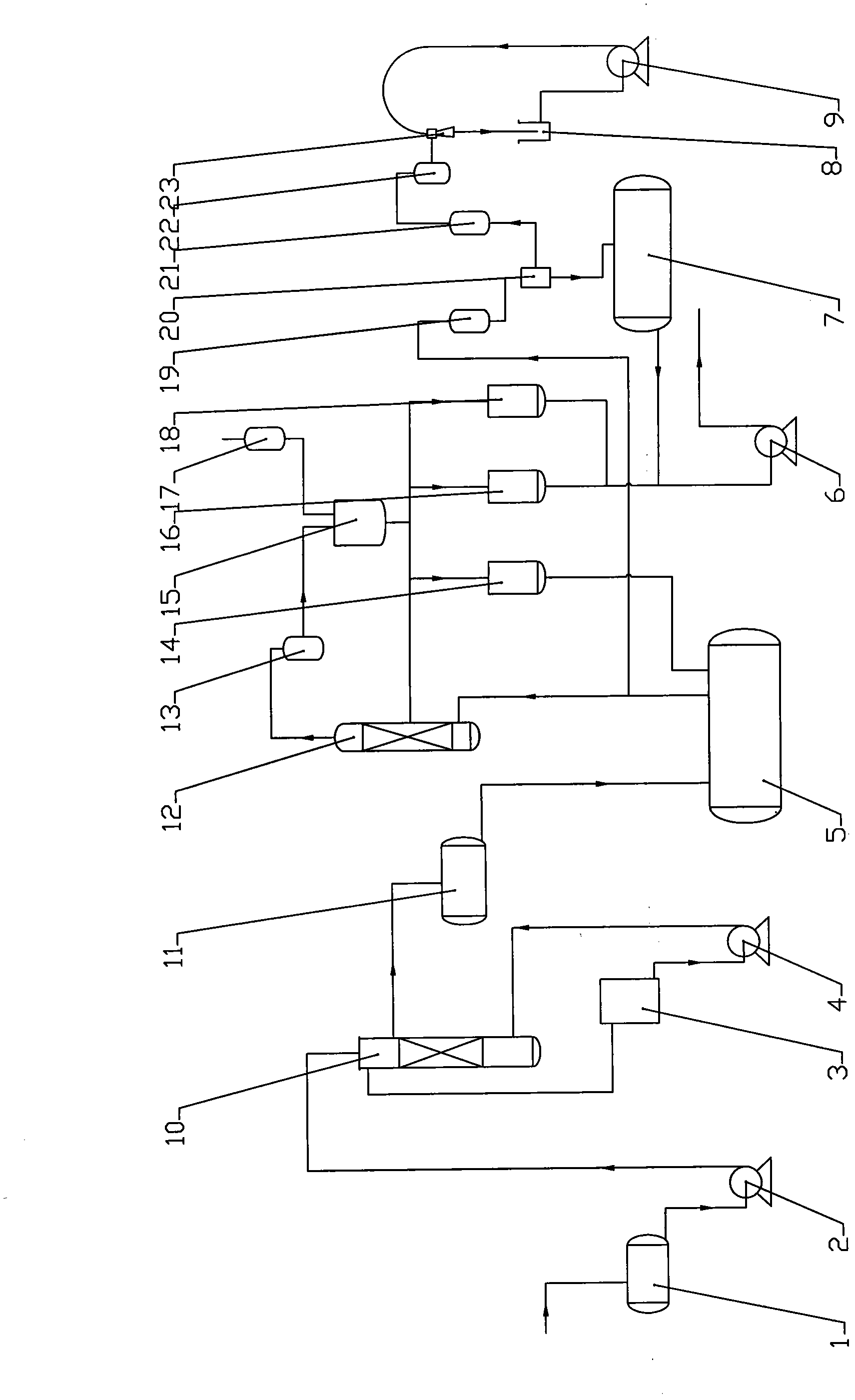

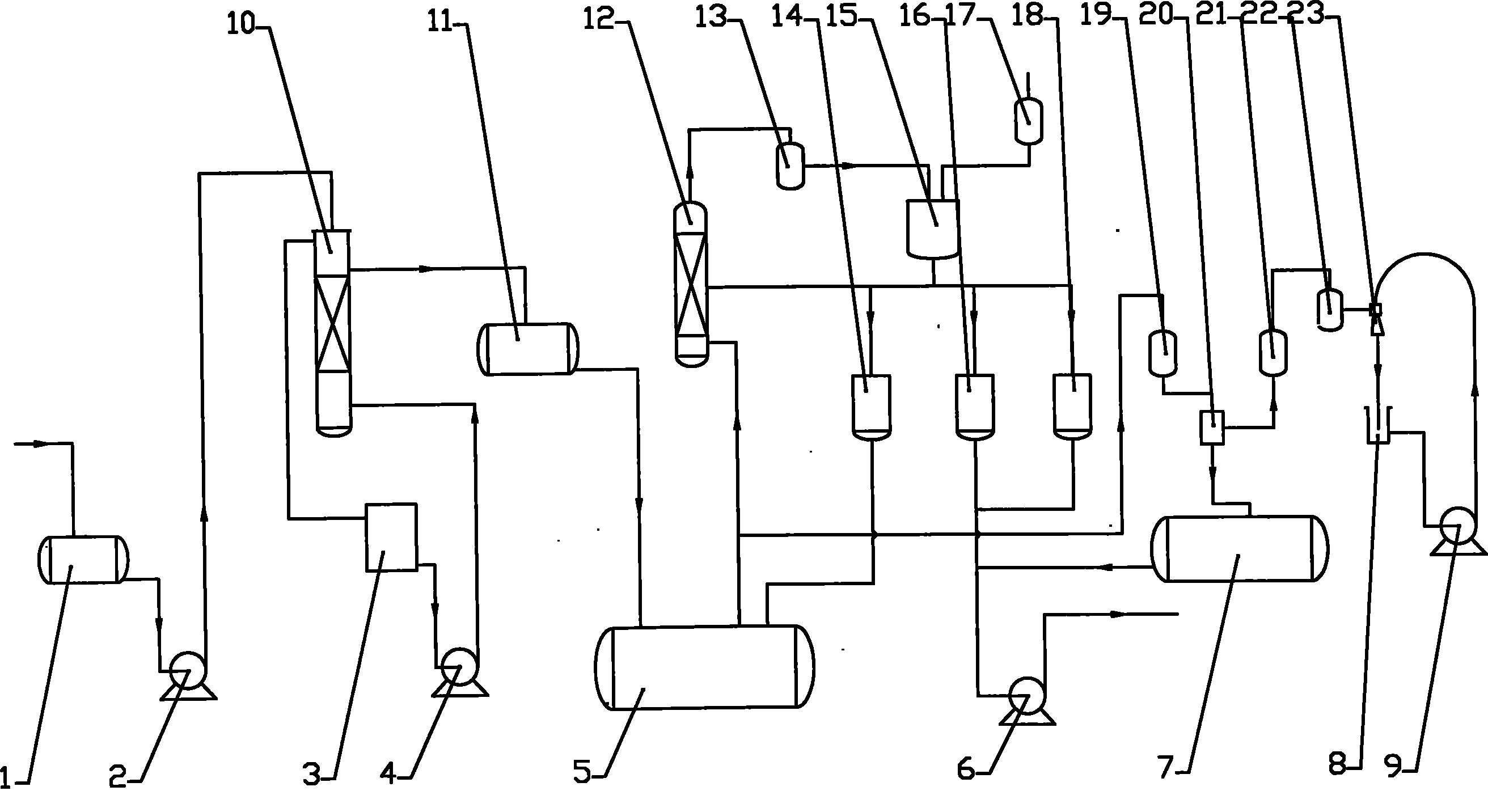

[0027] Embodiment, a kind of recovery method of raffinate in the production of trichlorethylene, comprises the following steps:

[0028] The raffinate produced in the trichlorethylene production process is collected in the top liquid tank 1, pumped into the alkali washing tower 10 with the feed pump 2, and there is 0.5% NaOH solution in the alkali washing tower 10, which is used to neutralize the raffinate acid, after the pretreatment of the alkali washing tower 10, the raffinate is collected in the neutralization top liquid tank 11, and the content of dichlorethylene in the neutralization top liquid tank 11 is about 5%, the content of trichlorethylene is about 65%, and the content of tetrachlorethylene is about 65%. The content of tetrachloroethane is about 20%, the content of tetrachloroethane is about 5%, and the content of pentachloroethane is about 5%. Then dichloroethylene, trichloroethylene, tetrachloroethylene, tetrachloroethane and pentachloroethane enter the still 5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com