Agent for purifying soil and/or underground water and purification method

A groundwater and purification agent technology, applied in the direction of chemical instruments and methods, restoration of contaminated soil, contaminated groundwater/leachate treatment, etc., can solve the problem that the oxidant cannot reach, prevent the decomposition of hydrogen peroxide, and expand the purification range, ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

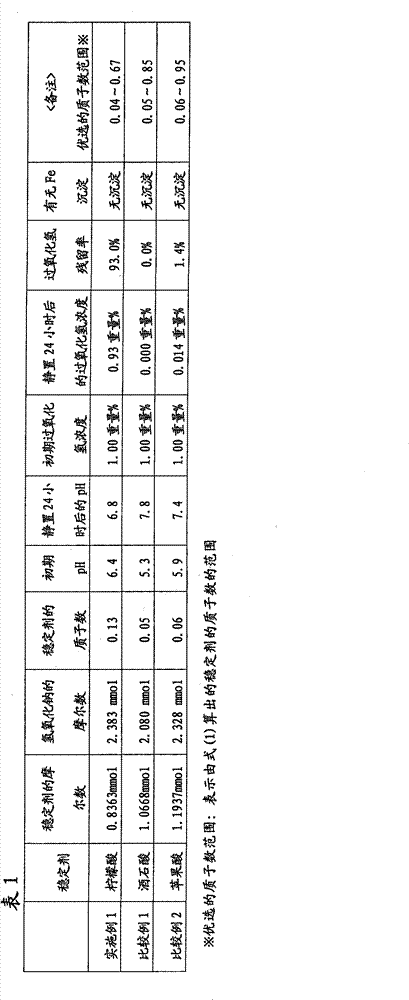

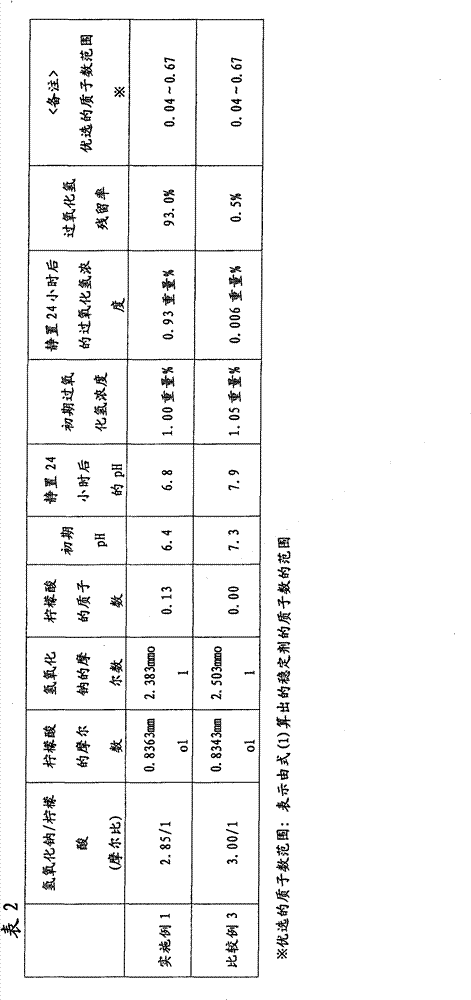

Embodiment 1

[0109] make FeSO 4 ·7H 2 O (Wako Pure Chemical Industries, Ltd., special grade reagent) was dissolved in pure water to prepare simulated groundwater. To a 35% by weight aqueous solution of hydrogen peroxide (manufactured by Mitsubishi Gas Chemical Co., Ltd., for industrial use), 20 parts by weight of citric acid (anhydrous) (manufactured by Kosho Chemical Co., Ltd.) was added to 100 parts by weight of hydrogen peroxide. special grade reagent), sodium hydroxide (made by Wako Pure Chemical Industries, Ltd., special grade reagent) in which the molar ratio of alkali and citric acid is sodium hydroxide / citric acid = 2.85 / 1 (molar ratio), and pure water (relative to peroxide The total amount of hydrogen and citric acid added was 568 parts by weight) and dissolved to prepare a scavenger (water content was 723 parts by weight relative to the total of 100 parts by weight of hydrogen peroxide and citric acid). The simulated groundwater and the purifying agent were mixed so that the hy...

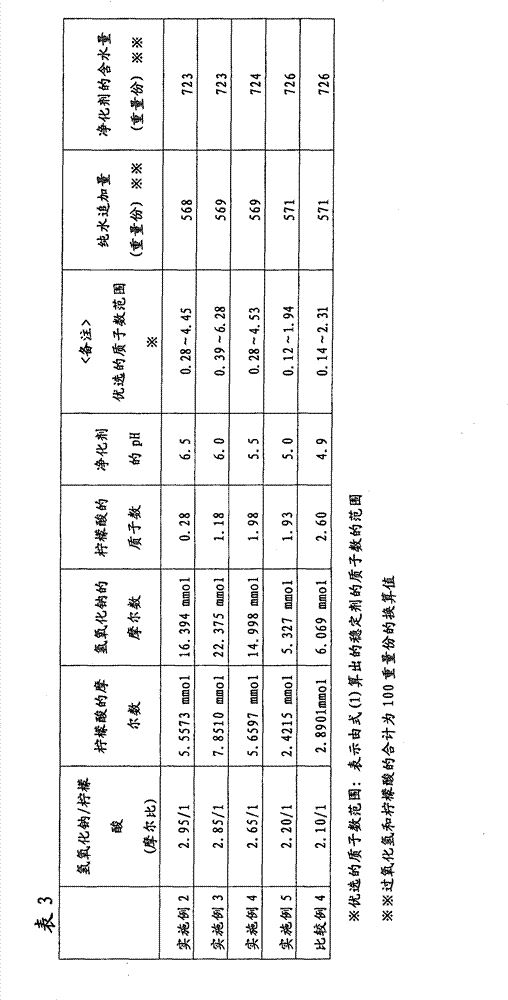

Embodiment 2~5

[0121] To a 35% by weight aqueous hydrogen peroxide solution (manufactured by Mitsubishi Gas Chemical Co., Ltd., for industrial use), 20 parts by weight of citric acid (anhydrous) (manufactured by Koso Chemical Co., Ltd.) was added to 100 parts by weight of hydrogen peroxide. , special grade reagent), sodium hydroxide and pure water and dissolve them to prepare a purifying agent. The molar ratio of the alkali and citric acid in the scavenger was sodium hydroxide / citric acid=2.95 / 1 to 2.20 / 1. Table 3 shows the amount of pure water added and the water content in the purifying agent. The pH of the prepared scavenger is shown in Table 3.

Embodiment 6

[0127] make FeSO 4 ·7H 2 O (Wako Pure Chemical Industries, Ltd., special grade reagent) was dissolved in pure water to prepare simulated groundwater. To a 35% by weight aqueous hydrogen peroxide solution (manufactured by Mitsubishi Gas Chemical Co., Ltd., for industrial use), 100 parts by weight of citric acid (anhydrous) (manufactured by Kosho Chemical Co., Ltd.) was added with respect to 100 parts by weight of hydrogen peroxide. Special-grade reagent), sodium hydroxide whose molar ratio of alkali and citric acid is sodium hydroxide / citric acid=2.85 / 1 (molar ratio), and pure water (100 parts by weight based on the total amount of hydrogen peroxide and citric acid added) , 278 parts by weight) and dissolved to prepare a scavenger (with respect to the total of 100 parts by weight of hydrogen peroxide and citric acid added, the water content is 370 parts by weight).

[0128] The simulated groundwater and the purifying agent were mixed so that the hydrogen peroxide concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com