Poly-pyrrole-2,5-di(polyol methane) adsorbent and preparation method thereof

A technology of adsorbent and alcohol methane, which is applied in the field of poly-pyrrole-2,5-diadsorbent and its preparation, can solve the problems of difficult treatment and complex components of industrial wastewater, and achieve low usage, excellent adsorption capacity, and large molecular weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

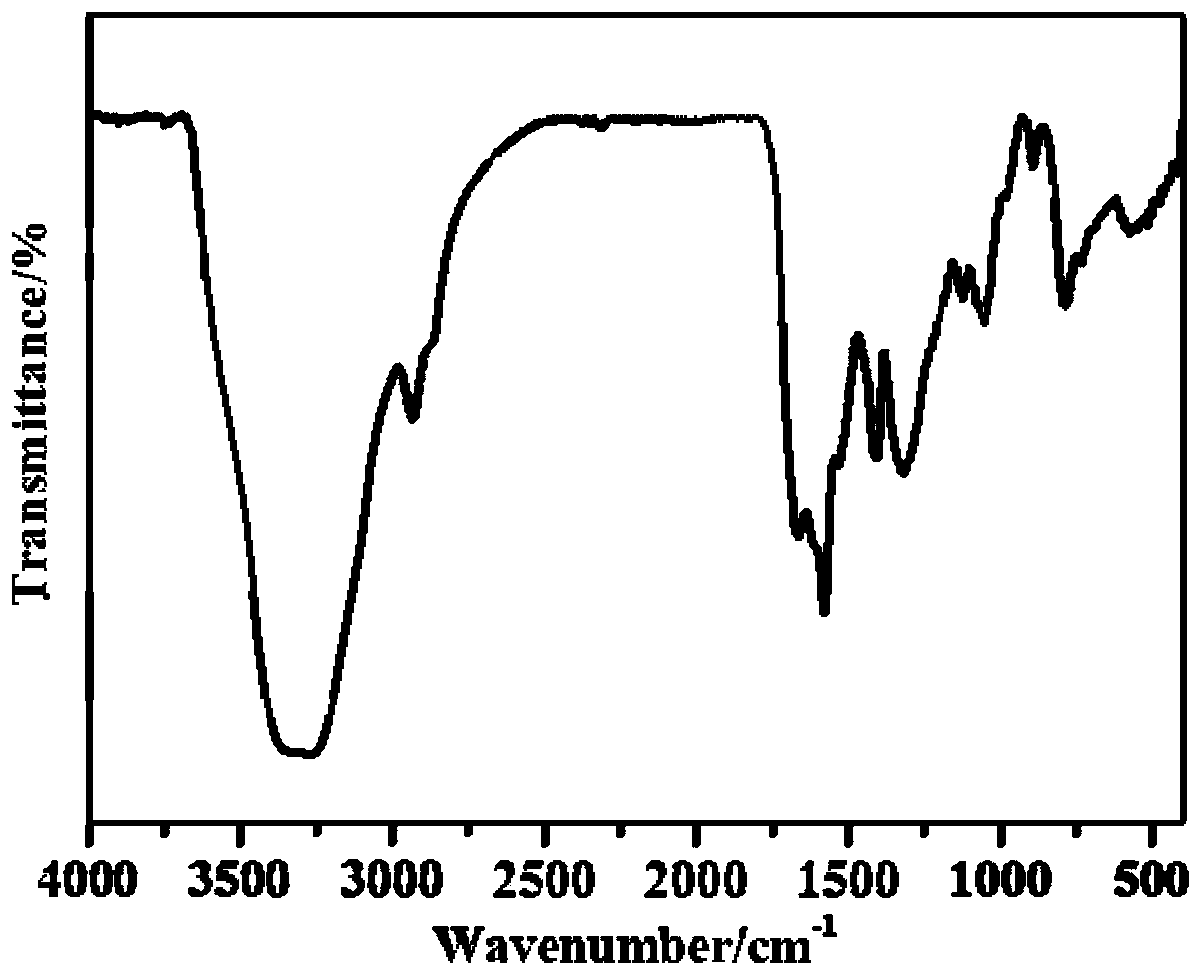

Image

Examples

Embodiment 1

[0028] preparation:

[0029] Add 100 mL of newly prepared deionized water into a three-neck flask with a specification of 500 mL, perform mechanical stirring at room temperature, and slowly inject 1 mL of pyrrole from the mouth of the bottle. After 1 h, 2 g of aliphatic aldehyde (taking glucose as an example) was dissolved in 15 mL of ionized water and slowly added to a three-necked flask with continuous stirring. After 1 h, 2 mL of concentrated hydrochloric acid was slowly injected into the reaction system, and stirring was continued at room temperature for 10 h. After the reaction, the resulting suspension is filtered and dried to obtain a black powder product, which is the polypyrromethane adsorption material.

[0030] application:

[0031] The prepared adsorbent was used to remove the cationic dye methylene blue in solution. Add 40mL of methylene blue solution with an initial concentration of 200mg / L to the dark brown bottle, add 0.08g of pre-alkali-treated adsorbent, a...

Embodiment 2

[0033] preparation:

[0034] Add 150 mL of newly prepared deionized water into a three-neck flask with a specification of 500 mL, perform mechanical stirring at room temperature, and slowly inject 2 mL of pyrrole from the bottle mouth. After 1.5 h, 4 g of glucose was completely dissolved in 15 mL of deionized water and slowly added into a three-neck flask that was continuously stirred. After 1.5 h, 4 mL of concentrated sulfuric acid was slowly injected into the reaction system, stirred at room temperature for 4 h, then heated to 60° C. and continued to stir for 6 h. After the reaction, the resulting suspension is filtered and dried to obtain a black powder product, which is the polypyrromethane adsorption material.

[0035] application:

[0036] The prepared adsorbent is used to remove the anthraquinone dye Alizarin Red s (anion) in the solution. Add 40mL of alizarin red s solution with an initial concentration of 200mg / L to the dark brown bottle, add 0.1g of the pre-acid-t...

Embodiment 3

[0038] preparation:

[0039] Add 200 mL of newly prepared deionized water into a three-neck flask with a specification of 500 mL, perform mechanical stirring at room temperature, and slowly inject 4 mL of pyrrole from the mouth of the bottle. After 2 hours, 8 g of glucose was completely dissolved in 15 mL of deionized water and slowly added into a three-necked flask with constant stirring. After 2h, 16mL of concentrated hydrochloric acid was slowly injected into the reaction system, stirring was continued at room temperature for 6h, and then heated to 80°C for 12h. After the reaction, the resulting suspension is filtered and dried to obtain a black powder product, which is the polypyrromethane adsorption material.

[0040] application:

[0041] The prepared adsorbent was used to remove the indigo dye indigo in the solution. Add 30mL of indigo solution with an initial concentration of 200mg / L to the darkened brown bottle, add 0.06g of adsorbent, and stir magnetically for 30m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com