Amphiphilic block copolymer formulations

A multi-block copolymer, copolymer technology, applied in bandages, absorbent pads, medical science, etc., can solve problems such as difficulty in polymer manufacturing, increase in viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0057] These controlled architecture amphiphilic block copolymers were synthesized using the following general scheme. Molecular weight is targeted by modulating the monomer-to-initiator concentration ([M] / [I]). The target molecular weight can thus be achieved by setting the [M] / [I] ratio, and then proceeding the polymerization to the desired conversion necessary to achieve the target molecular weight. Monomer conversion can be conveniently monitored by gas chromatography (GC) analysis or by rapid devolatilization of unreacted monomer under vacuum. These polymer samples were run neat or in solution. Typical solvents used include: dioxane, n-methylpyrrolidone, dimethylacetamide, dimethylformamide, t-butanol, n-butanol, toluene, ethylbenzene, methyl acetate, ethyl acetate, Propyl acetate, butyl acetate, ethanol, cyclohexanone, cyclopentanone, and methyl ethyl ketone. Polymerization reactions are run at ambient pressure, or run under nitrogen pressure up to 100 psi. Polymeriz...

Embodiment 1

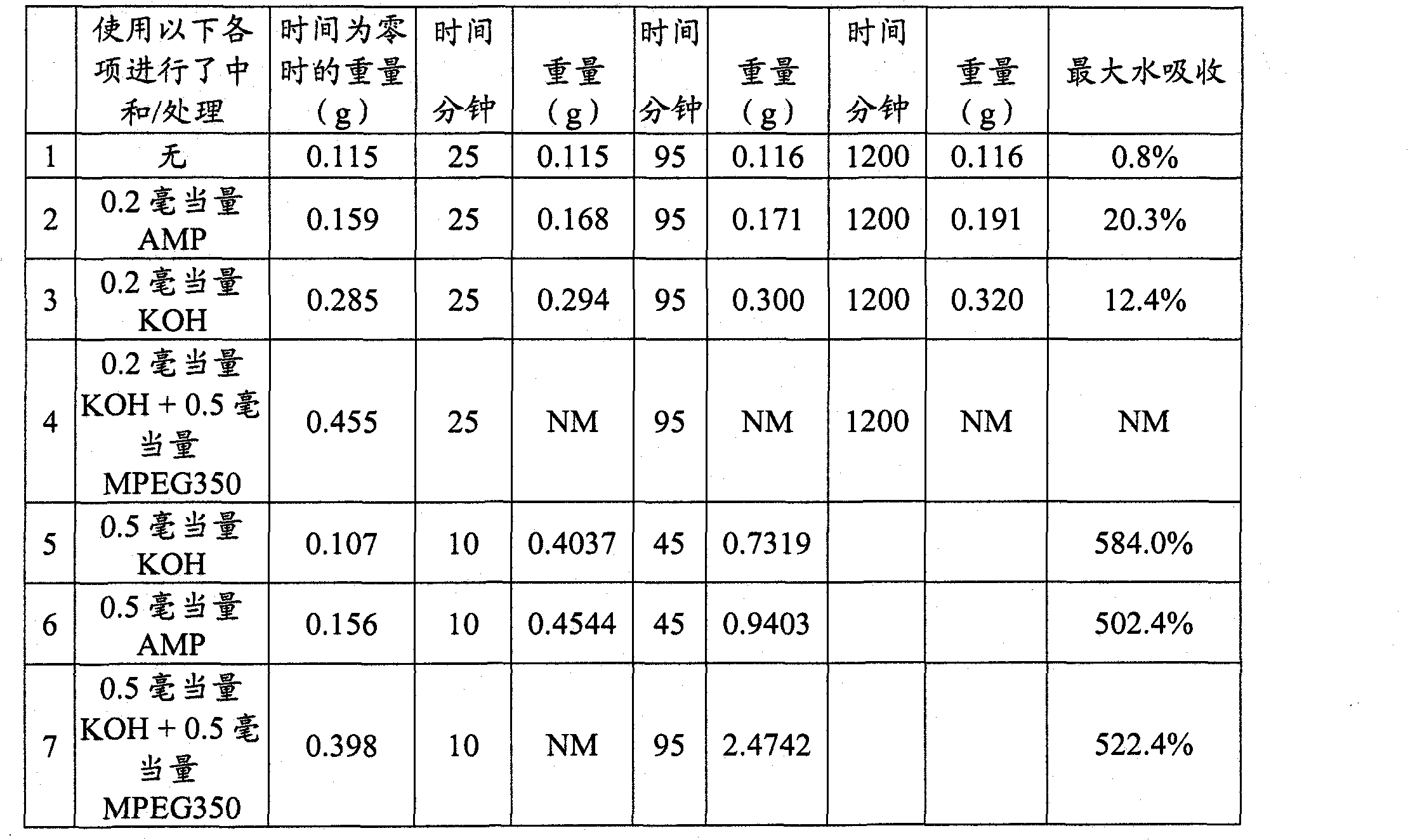

[0066] An ABA triblock copolymer containing A blocks (PMMA / BA) and B blocks (PAA / BA) was prepared to give PMMA / BA-b-PAA / BA-PMMA / BA triblock copolymers , the A block includes polymethyl methacrylate and polybutyl acrylate and the B block is polyacrylic acid and polybutyl acrylate. The hydrophilic midblock contains about 20 wt% AA. Films of the above polymers were prepared by first dissolving the polymers in ethyl acetate followed by addition of base and / or plasticizer / diluent. These solutions were cast into thin films (about 5 mm thick) and dried under vacuum to remove all residual solvent and monomer. These polymer films were then placed in water and reweighed at various times to determine the magnitude or absorption. The results of preneutralization and plasticization are given in Table 1 below.

[0067] In each case, these pre-neutralized samples absorbed >20% of the maximum amount in less than 26 minutes. In contrast, the unneutralized sample absorbed much less than 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com