Composite dielectric protective film of plasma display panel (PDP) and preparation method thereof

A composite medium and display panel technology, used in tube/light screen manufacturing, solid cathode components, discharge tubes, etc., can solve problems such as inability to take into account simultaneously, unstable oxides, process difficulties, etc., to improve service life, reduce Production cost, effect of reducing discharge delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

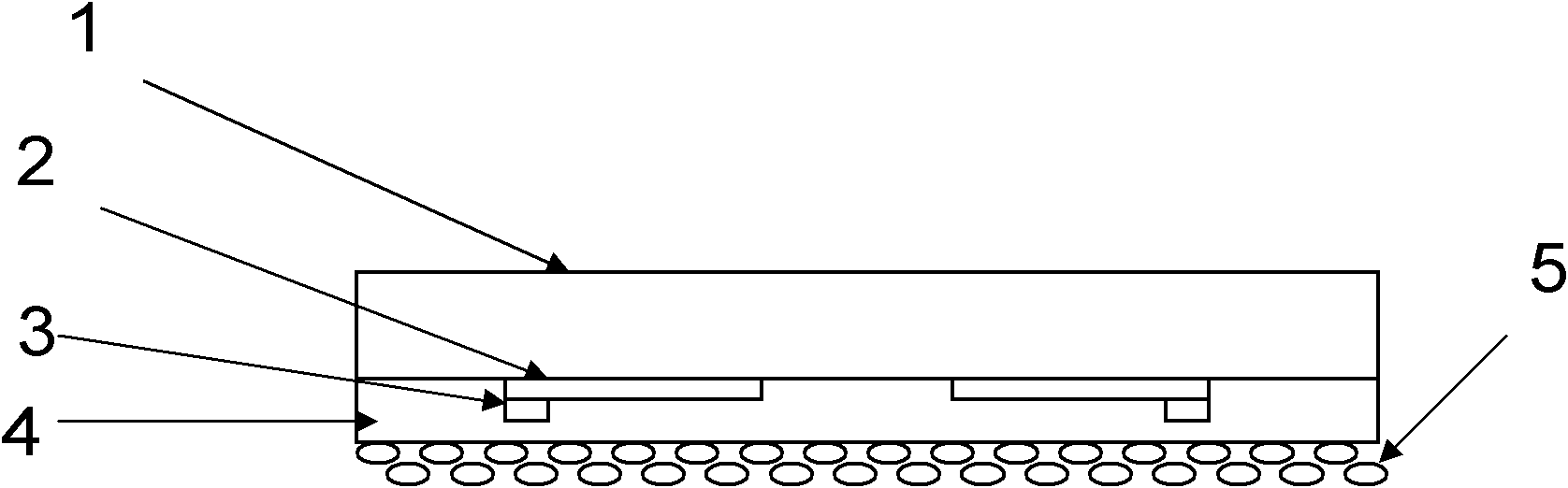

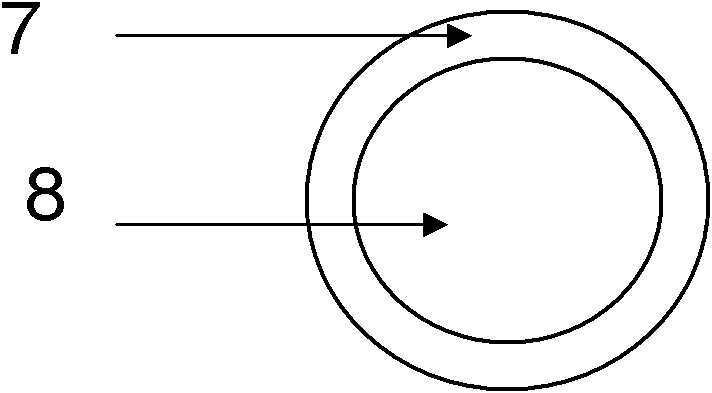

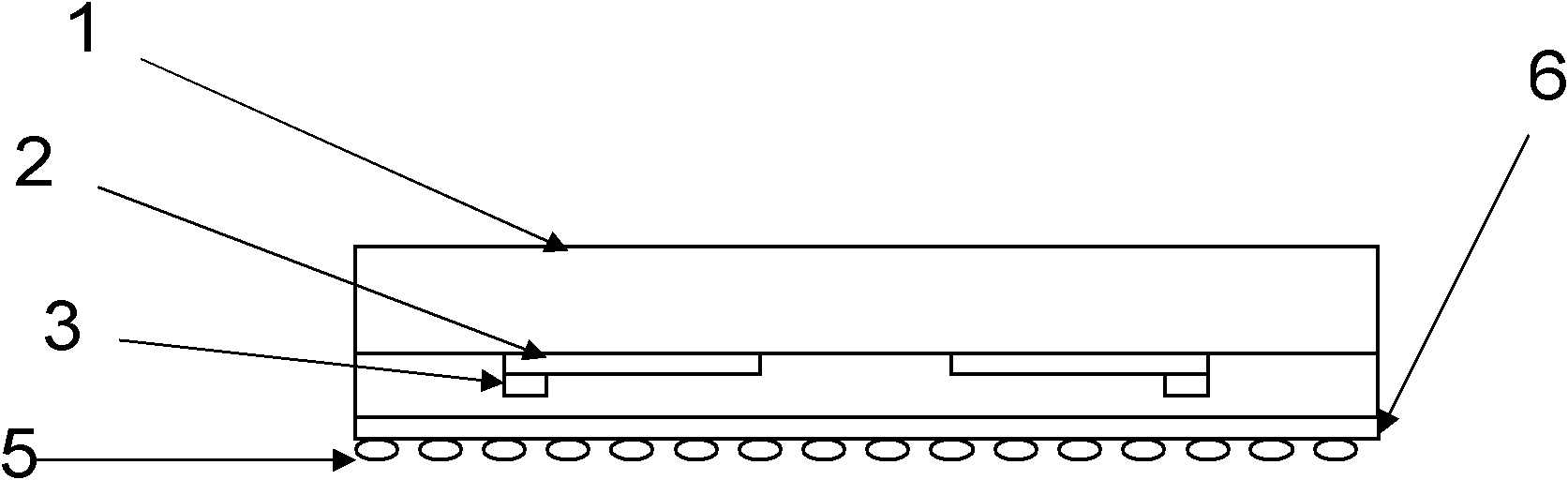

[0048] Select CaO particles with an average particle size of 1-2 μm and place them in the crucible of a thermal evaporation furnace. The crucible is equipped with a stirring device. The evaporation furnace uses Mg as the evaporation source. O 2 As a carrier gas, thermal evaporation coating is carried out, and when MgO with a thickness of 50nm is formed on the surface of CaO, the coating is stopped, and crystal particles with a core-shell structure are prepared.

[0049] Put the crystal particles in the carrier solvent cellulose ether, and form a uniformly dispersed slurry after being punctured. Use a coating machine to evenly disperse the slurry on the surface of the medium layer. After drying at 150°C for 30 minutes, place it in a sintered In the furnace, it is sintered at 550°C to form a transparent composite dielectric protective film.

Embodiment 2

[0051] Select SrO particles with an average particle size of 1-2 μm and place them in the crucible of a thermal evaporation furnace. The crucible is equipped with a stirring device. The evaporation furnace uses Mg as the evaporation source. O 2 As the carrier gas, thermal evaporation coating is carried out, and when MgO with a thickness of 50nm is formed on the surface of SrO, the coating is stopped, and crystal particles with a core-shell structure are prepared.

[0052] Put the crystal particles in the carrier solvent cellulose ether, and form a uniformly dispersed slurry after being punctured. Use a coating machine to evenly disperse the slurry on the surface of the medium layer. After drying at 150°C for 30 minutes, place it in a sintered In the furnace, it is sintered at 550°C to form a transparent composite dielectric protective film.

Embodiment 3

[0054] Select ZnO particles with an average particle size of 1-2 μm and place them in the crucible of a thermal evaporation furnace. The crucible is equipped with a stirring device. The evaporation furnace uses Mg as the evaporation source. O 2 As the carrier gas, thermal evaporation coating is carried out, and when MgO with a thickness of 50nm is formed on the surface of ZnO, the coating is stopped, and crystal particles with a core-shell structure are prepared.

[0055] Put the crystal particles in the carrier solvent cellulose ether, and form a uniformly dispersed slurry after being punctured. Use a coating machine to evenly disperse the slurry on the surface of the medium layer. After drying at 150°C for 30 minutes, place it in a sintered In the furnace, it is sintered at 550°C to form a transparent composite dielectric protective film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com