Processing method of Cantonese sausage

A processing method and sausage technology, which is applied in the processing field of Cantonese-flavored sausage, can solve the problems of long production cycle, low production efficiency, unfavorable industrial production, etc., and achieve the effects of improving production efficiency, increasing nutritional content, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

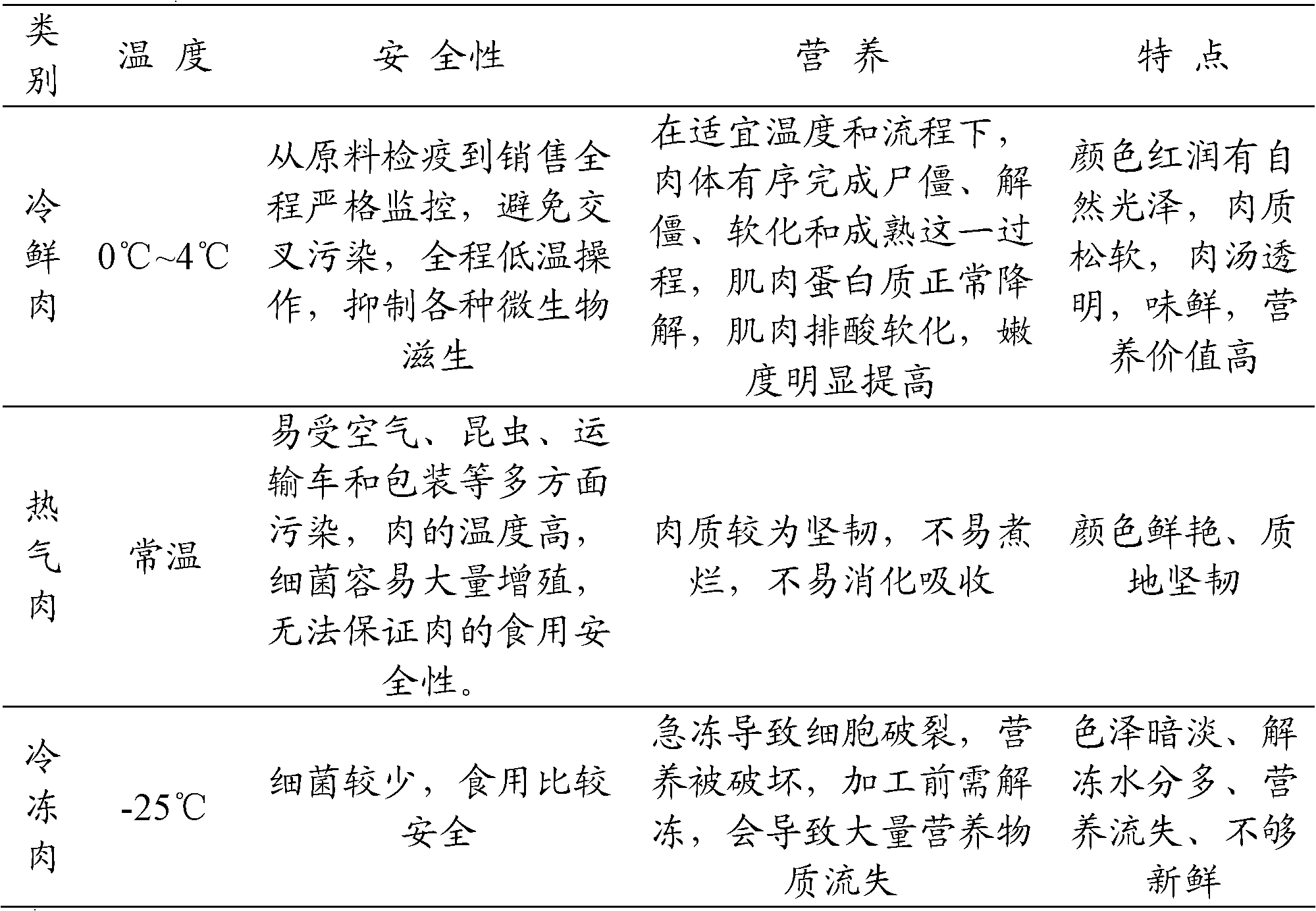

[0072] Separate the fat and lean meat of chilled fresh meat at 0℃~4℃, and carry out the following treatment on the fat: remove the impurities such as blood and oil on the fat and put it on a dicing machine to make 0.5cm*0.5 cm of fat fat; 30kg of the fat fat is washed in ice water after washing in 35°C warm water, and the fat paste of the fat fat and the oil slick on the surface are cleaned; 0.6kg of salt is evenly sprinkled on the cleaning On the clean fat diced fat, put it into the bucket and marinate for 12 hours to obtain diced fat;

[0073] After removing impurities such as fascia, grease, blood stains, brittle bones and pig skins on the lean meat, trim and cut it into meat pieces, and mince 70kg of the meat pieces into 8mm diced meat;

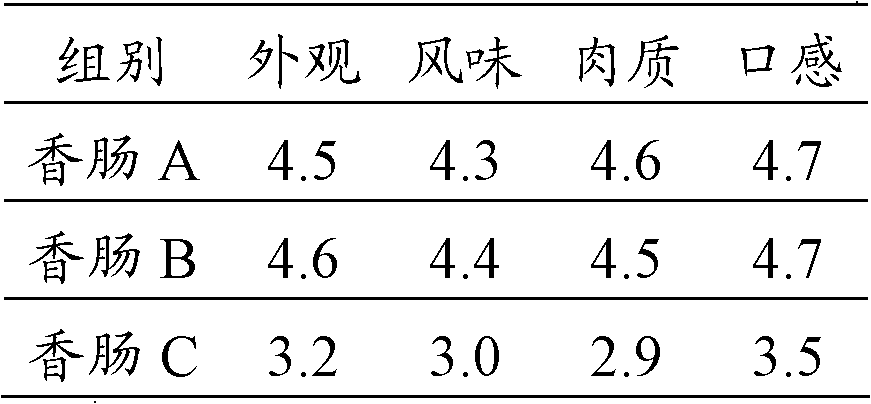

[0074] Add 2kg cooking wine to described fat diced, after mixing, add refined meat diced, after mixing again, add 13kg white sugar, 2.45kg salt, 0.8kg cooking wine, 0.03kg sodium iscorbate and 0.3kg sodium lactate, after stirring Marinat...

Embodiment 2

[0078] Separate the fat and lean meat of chilled fresh meat at 0℃~4℃, and carry out the following treatment on the fat: remove the impurities such as blood and oil on the fat and put it on a dicing machine to make 0.5cm*0.5 cm of fat fat; 30kg of the fat fat is washed in ice water after being washed in 40°C warm water, and the fat paste of the fat fat and the oil slick on the surface are cleaned; 0.5kg of salt is evenly sprinkled on the cleaning On the clean fat diced fat, put it into the bucket and marinate for 14 hours to obtain diced fat;

[0079] After removing impurities such as fascia, grease, blood stains, brittle bones and pig skins on the lean meat, trim and cut it into meat pieces, and mince 70kg of the meat pieces into 8mm diced meat;

[0080] Add 2kg cooking wine to described fat diced, after mixing, add refined meat diced, after mixing again, add 13kg white sugar, 2.45kg salt, 0.8kg cooking wine, 0.03kg sodium iscorbate and 0.3kg sodium lactate, after stirring Ma...

Embodiment 3

[0084] Separate the fat and lean meat of chilled fresh meat at 0℃~4℃, and carry out the following treatment on the fat: remove the impurities such as blood and oil on the fat and put it on a dicing machine to make 0.5cm*0.5 cm of fat fat; 30kg of the fat fat is washed in ice water after washing in 35°C warm water, and the fat paste of the fat fat and the oil slick on the surface are cleaned; 0.6kg of salt is evenly sprinkled on the cleaning On the clean fat diced fat, put it into the bucket and marinate for 12 hours to obtain diced fat;

[0085] After removing impurities such as fascia, grease, blood stains, brittle bones and pork skin on the lean meat, trim and cut it into meat pieces, inject 0.35kg of ginseng extract into the 70kg meat pieces and perform rolling and kneading treatment, and roll the rolled meat. The meat pieces after kneading are minced into 8mm diced meat; wherein, the ginseng extract is prepared according to the following method:

[0086] Pulverize 500 g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com