Nickel-based catalyst prepared through solid-phase thermal dispersion and preparation method thereof

A nickel-based catalyst, catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as active component loading, and achieve the effects of promoting dispersion, improving stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

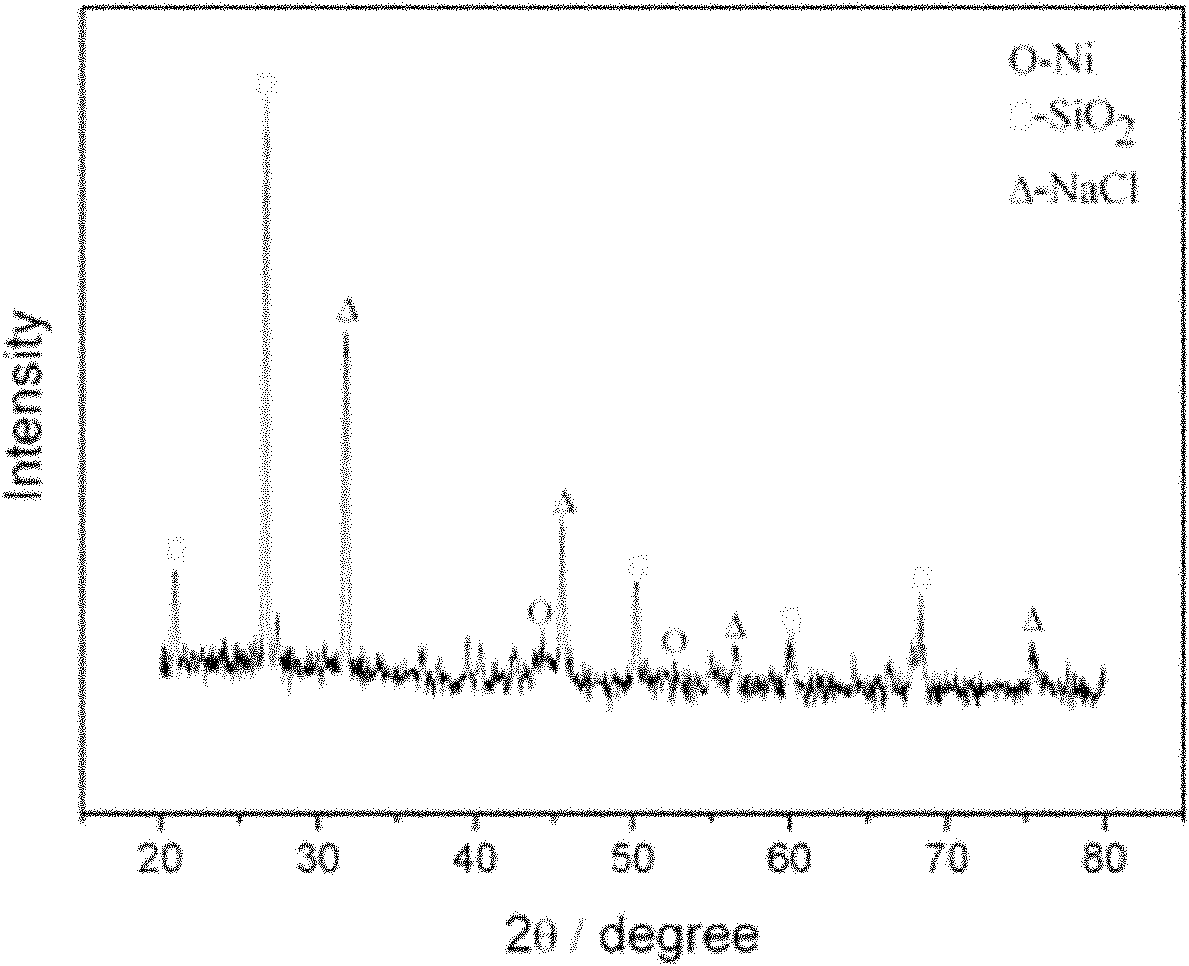

Image

Examples

Embodiment 2

[0028] Adopt the same method with embodiment 1, just use 5.30g Ni(CH 3 COO) 2 .4H 2 O as a nickel salt precursor. The prepared catalyst was used for evaluation in the catalytic hydrogenation reaction of p-nitrophenol. When the reaction was carried out for 760 minutes, the conversion rate of p-nitrophenol was 99.5%, and the product selectivity was 99.6%.

Embodiment 3

[0030] Adopt the same method with embodiment 1, just use 6.19g Ni (NO 3 ) 2 .6H 2 O as a nickel salt precursor. The prepared catalyst was used for evaluation in the catalytic hydrogenation reaction of p-nitrophenol. When the reaction was carried out for 800 min, the conversion rate of p-nitrophenol was 99.5%, and the product selectivity was 99.5%.

Embodiment 4

[0032] Adopt the same method with embodiment 1, just use 5.60g NiSO 4 .6H 2 O as a nickel salt precursor. The prepared catalyst was used for evaluation in the catalytic hydrogenation reaction of p-nitrophenol. When the reaction was carried out for 540 minutes, the conversion rate of p-nitrophenol was 99.5%, and the product selectivity was 99.6%.

[0033] The catalysts prepared in the above Examples 1-4 were used in the catalytic hydrogenation reaction of p-nitrophenol, and the activity of the catalysts was compared by the conversion rate of the raw materials and the selectivity of the products. The hydrogenation reaction of p-nitrophenol catalyzed by the above four kinds of catalysts, when the conversion rate of p-nitrophenol and the selectivity of p-aminophenol all reach more than 99.5%, it can be seen from the complete comparison of the time required for the reaction that nickel acetate and Nickel nitrate is the catalyst prepared by the precursor of nickel salt, the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com