Method for recycling stainless steel neutral salt electrolysis waste solution

A technology of electrolyzing waste liquid and neutral salt, which is applied in the field of environmental technology and resource recovery, and can solve the problems of unrecoverable nickel ions and low sludge utilization value, and achieve the effect of low resources and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

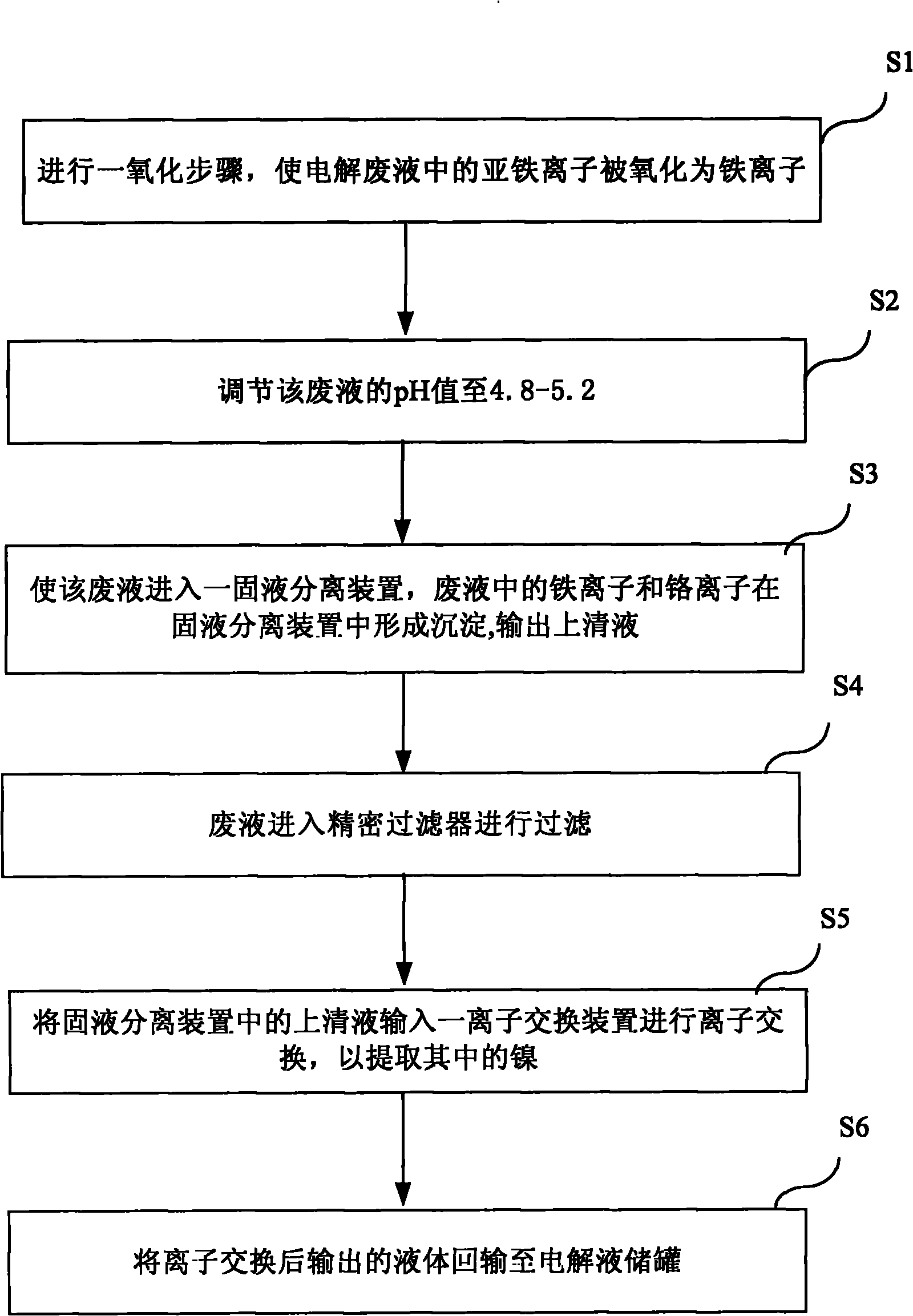

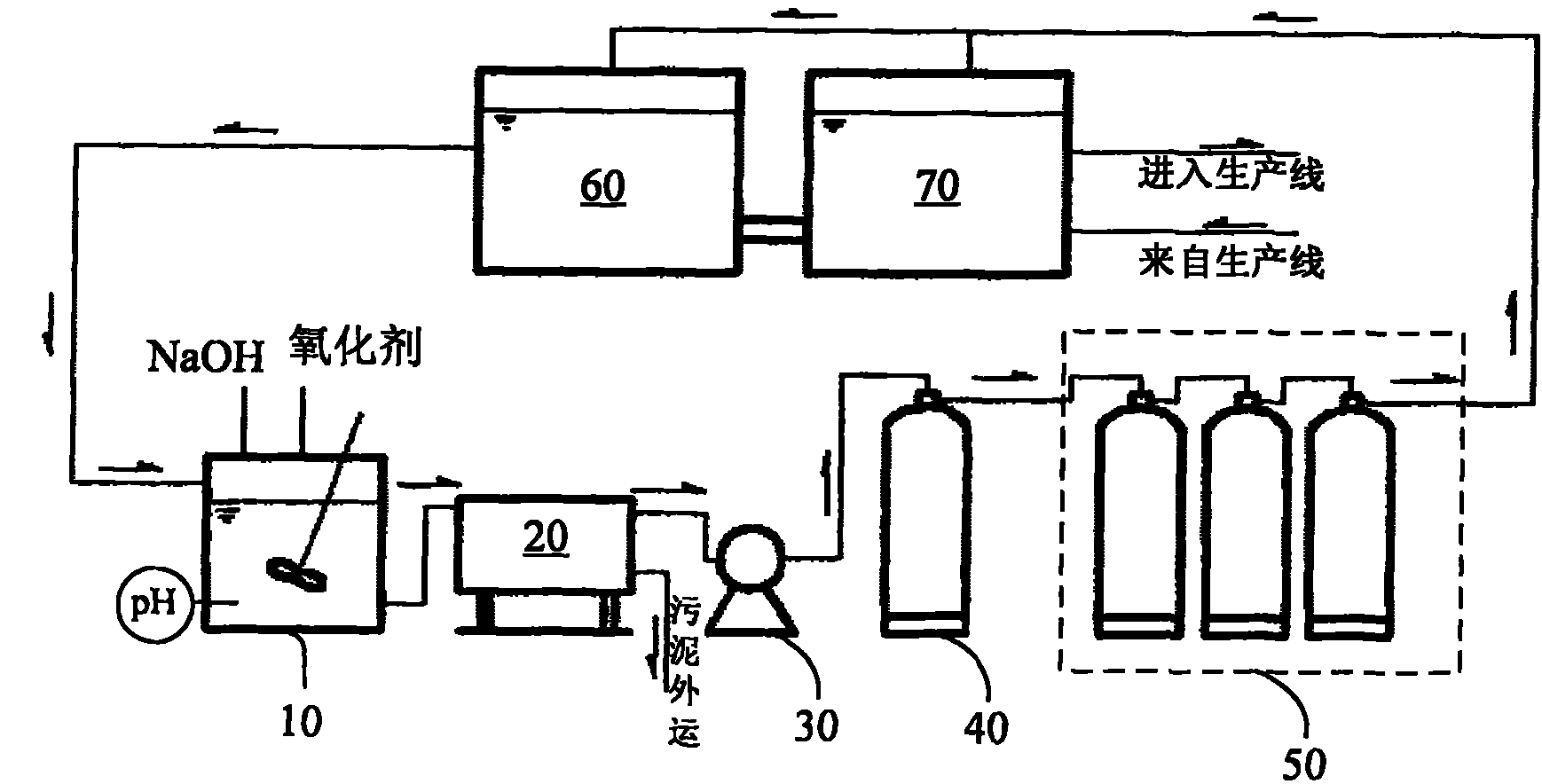

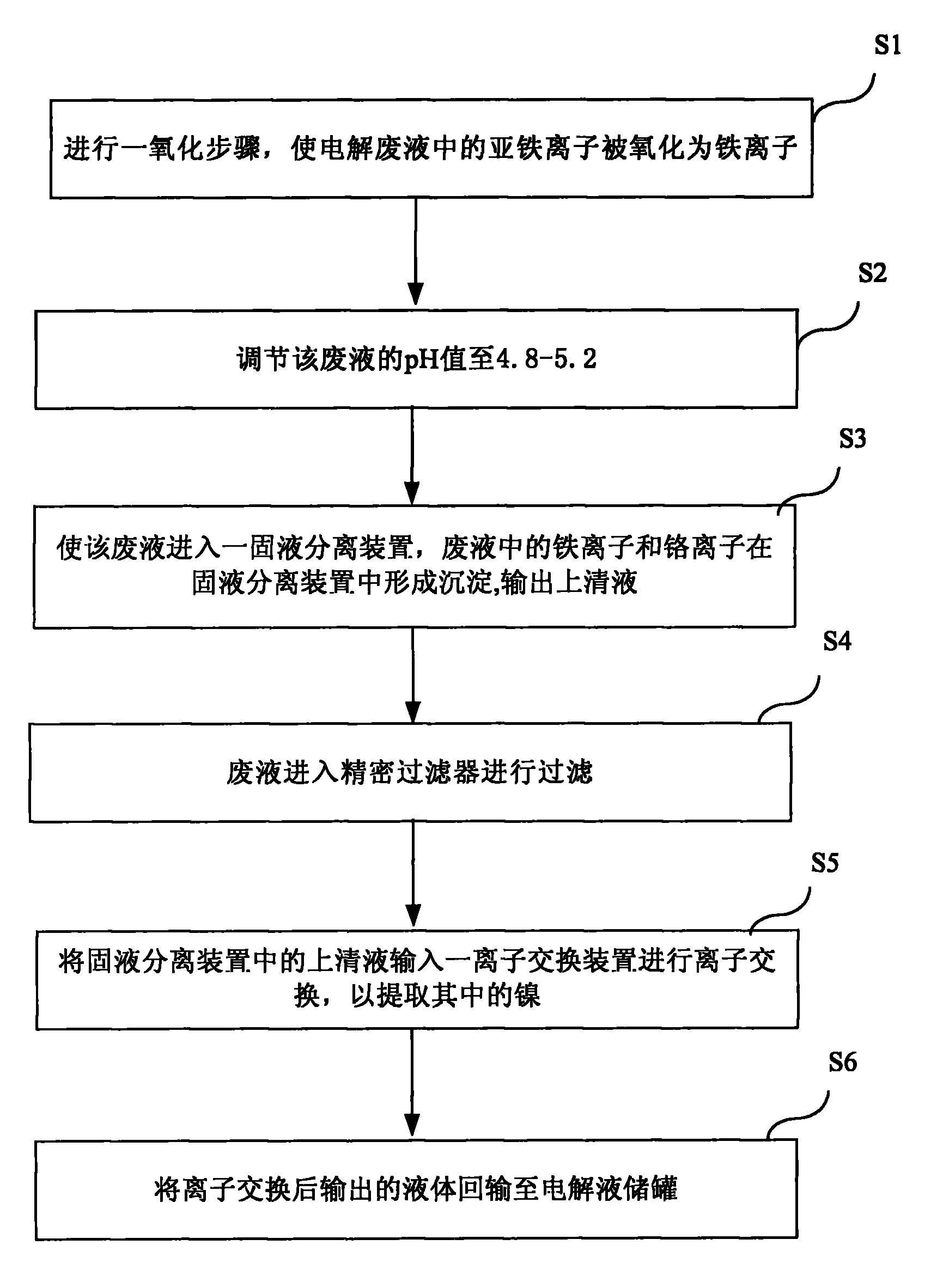

[0021] The invention provides a recycling method for stainless steel neutral salt electrolysis waste liquid. One aspect of the method is to extract nickel ions from the waste liquid to achieve the purpose of recycling. To achieve this, it is necessary to first remove the waste liquid Interference from other metal ions. On the other hand, since waste liquid (mainly refers to the solution containing electrolyte) needs to be reused, it is necessary to ensure that no new impurities are introduced into the process of the method.

[0022] The analysis and detection results of the stainless steel neutral salt electrolysis waste liquid show that the main metal ion in the stainless steel neutral salt electrolysis waste liquid is Fe 2+ , Fe 3+ , Ni 2+ , Cr 3+ , and the rest are electrolytes (Na 2 SO 4 ). The pH value of the electrolytic waste solution varies greatly, generally in the range of 2-6. Because of the difference in pH value, the content of metal ions is also very diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com