Excess sludge wall-breaking and cell-dissolving method and device

A technology for excess sludge and cell lysis, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of excess sludge rise, unfavorable sludge aerobic treatment or anaerobic digestion , can not be industrialized and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

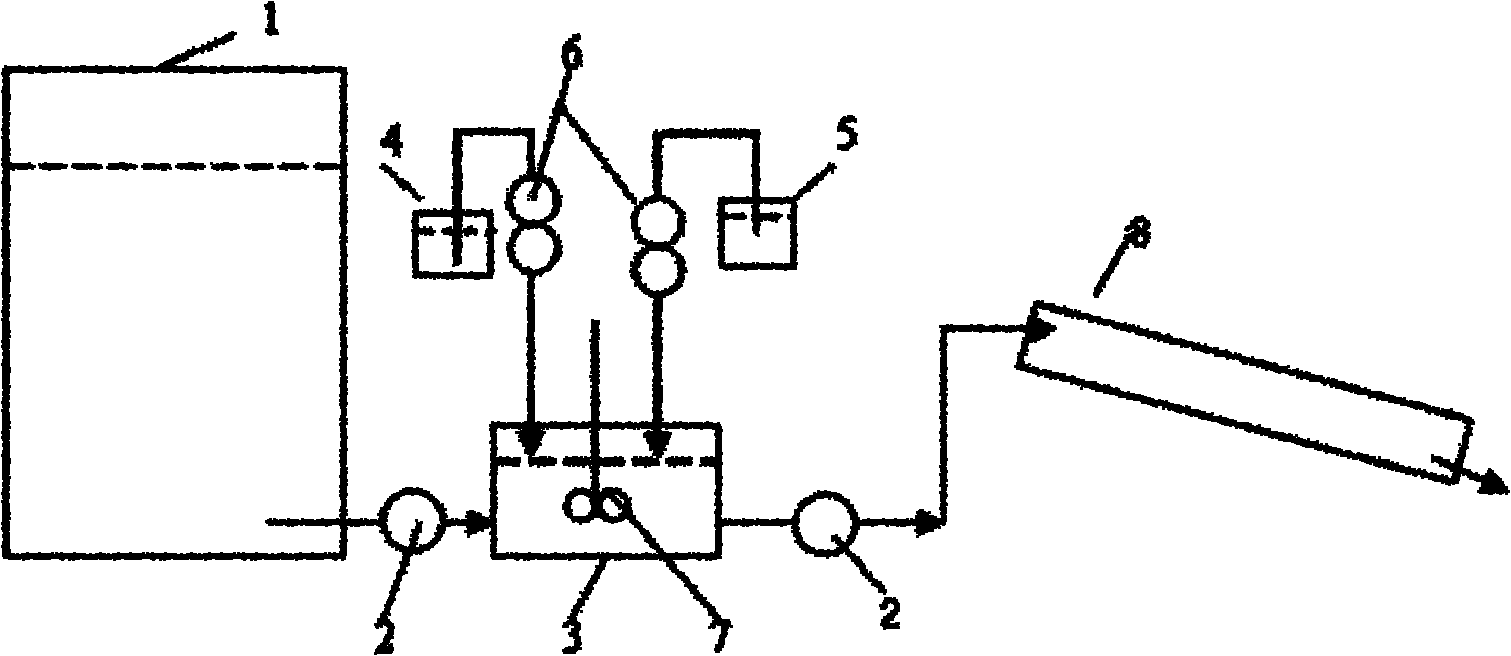

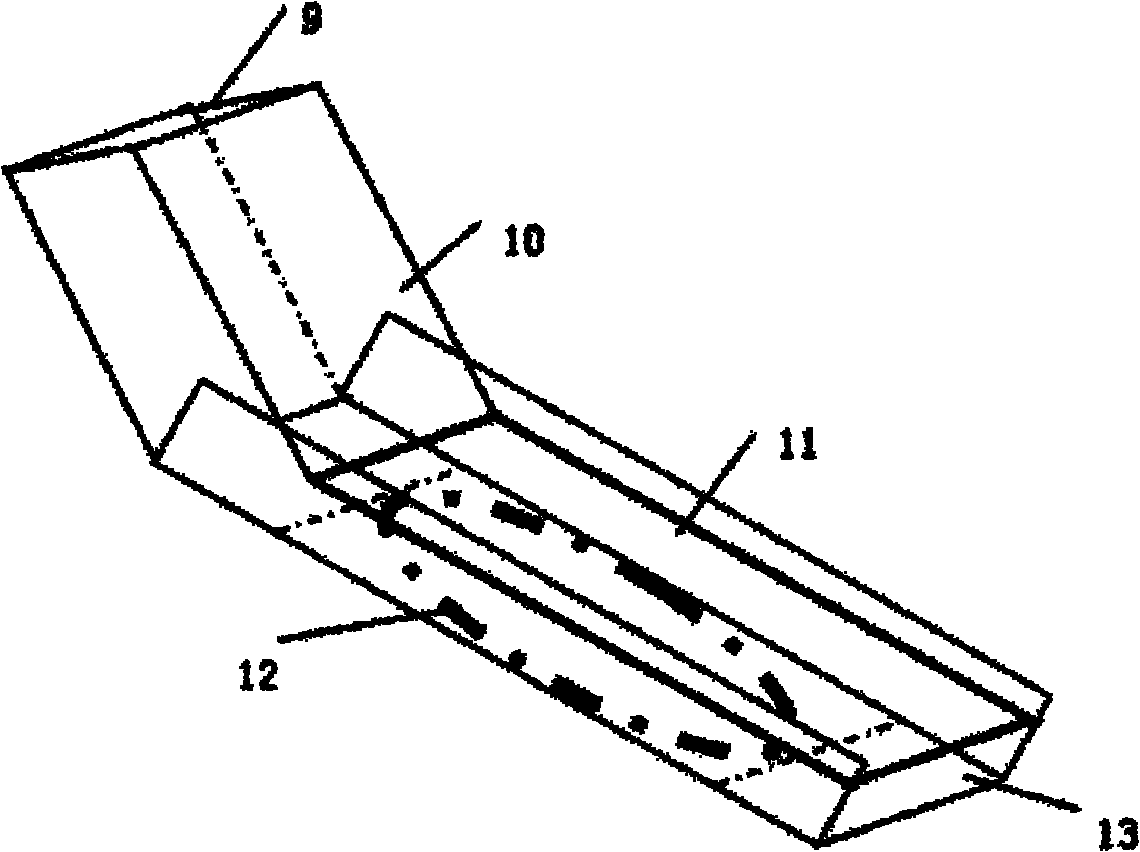

[0026] The structure of the trough ultrasonic equipment is attached figure 1 shown. The groove type ultrasonic frequency is 20kHz, the power is 100W, there is one transducer, the diameter of the transducer is 68mm, the length of the sound field in the groove is 0.15m, and the width is 0.15m. Take the residual sludge of a sewage plant in Tianjin as an example. The remaining sludge in the gravity concentration tank 1 is pumped into the mixing tank 3 through the sludge pump 2, and then the chemical reagents in the sodium hydroxide solution tank 4 and the Tween solution tank 5 are added to the mixing tank through the peristaltic pump 6, and in the process of mechanical stirring 7 The sludge is fully mixed under the action, and then the sludge is pumped into the trough equipment 8 by the sludge pump 2, and enters the feed hopper 10 through the trough ultrasonic inlet 9, and the sludge pressure, gravity and fluid distributor 11 in the feed hopper Under the combined action, throug...

Embodiment 2

[0030] Operation process is identical with embodiment 1. The difference is that the ultrasonic frequency is 25kHz, and other conditions are shown in Table 2. The wavelength is 60mm (half wavelength is 30mm)), and the "near field" distance is 19.3mm. The lysis efficiency under different conditions is shown in Table 2.

[0031] Table 2 Lysis rate and cost under different conditions

[0032]

Embodiment 3

[0034] Operation process is identical with embodiment 1. The difference is that the frequency is 28kHz, see Table 2 for other conditions. The wavelength is 54mm (half wavelength is 27mm), and the "near field" distance is 21.4mm. The lysis efficiency under different conditions is shown in Table 3.

[0035] Table 1 Lysis rate and cost under different conditions

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com