Composite ceramic mold core for water pump impeller and preparation method thereof

A technology of composite ceramics and water pump impeller, which is applied in the field of material processing engineering, can solve the problems of low surface finish and dimensional accuracy of impeller castings, low surface finish of cores, easy occurrence of cracks and fractures, etc., so as to improve the preparation and use performance. , The effect of simple manufacturing process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

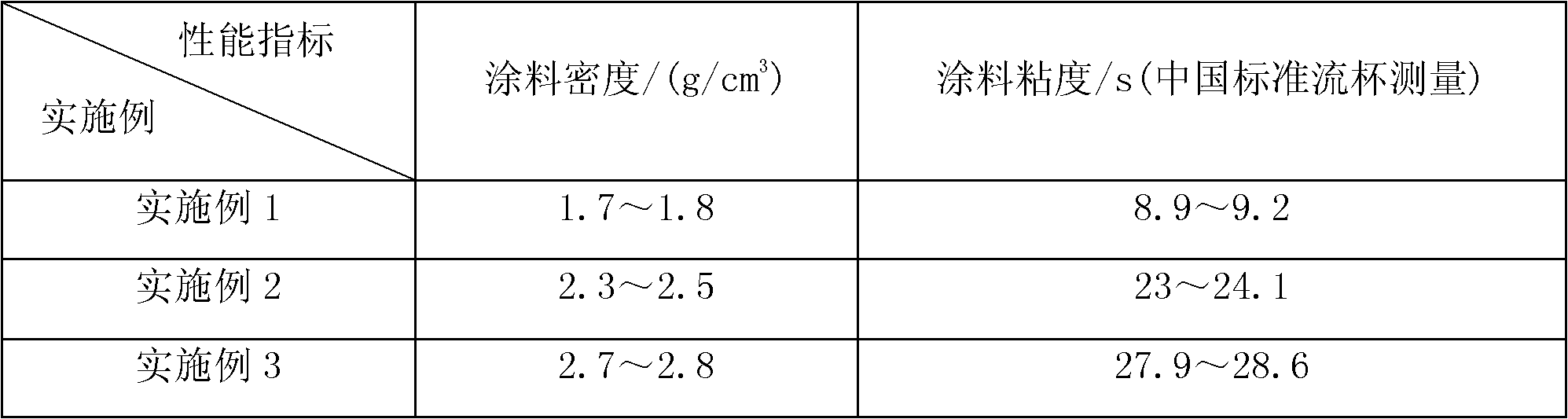

Embodiment 1

[0029] 1) Using 12 parts of silica sol (ω(SiO 2 =30% / Kg)) as the binding agent of the composite ceramic core coating, adopt 32 parts of 280 purpose high refractoriness refractory material powders (fused corundum: calcium carbonate=1: 0.1) as the composite ceramic core coating Basic materials, then add 2 parts of low-alkali glass fiber chopped strands with a length of 3 to 5mm, 15 parts of defoamer (such as ZF-100 type silicone defoamer), 1 part of disintegrating agent (edible glucose powder) and 1 part of Part grain refiner (cobalt aluminate and its oxide), the above components are uniformly dispersed, fully mixed and wetted, using a low-speed continuous mixer to stir the paint, and after 24 hours of uninterrupted stirring, the prepared The coating of the composite ceramic core is used for coating when making the core.

[0030] 2) A gelation method using dry hardening is adopted in the preparation process of the composite ceramic core. First, use the core mold to evenly appl...

Embodiment 2

[0033] 1) Using 13 parts of silica sol (ω(SiO 2 =30% / Kg)) as the binding agent of the composite ceramic core coating, adopt 34 parts of 340 purpose high refractoriness refractory material powders (fused corundum: calcium carbonate=1: 0.5) as the composite ceramic core coating Basic materials, then add 3 parts of low-alkali glass fiber chopped strands with a length of 3 to 5 mm, 16 parts of defoaming agent (n-octanol), 1.5 parts of disintegrating agent (edible glucose powder) and 1.5 parts of grain refiner ( Aluminate and its oxides), the above components are uniformly dispersed, fully mixed and wetted, using a low-speed continuous mixer to stir the coating, and after 24 hours of uninterrupted stirring, the coating for the composite ceramic core is prepared. Used for coating when making cores.

[0034] 2) A gelation method using dry hardening is adopted in the preparation process of the composite ceramic core. First, use the core mold to evenly apply the coating of the compos...

Embodiment 3

[0037] 1) Using 14 parts of silica sol (ω(SiO 2 =30% / Kg)) as the binding agent of composite ceramic core coating, adopt the refractory material powder (fused corundum: calcium carbonate=1: 1) of the high refractoriness of 36 parts of 400 purposes as the composite ceramic core coating Basic materials, then add 4 parts of low-alkali glass fiber chopped strands with a length of 3 to 5mm, 17 parts of defoamer (defoamer GP (ethylene glycol butyl ether phosphate)), 2 parts of disintegrator (edible glucose powder ) and 2 parts of grain refiner (nickel aluminate and its oxide), uniformly disperse the above components, fully mix and wet each other, use a low-speed continuous mixer to stir the coating, after 24 hours of uninterrupted stirring , Prepare the coating for the composite ceramic core for coating when making the core.

[0038] 2) A gelation method using dry hardening is adopted in the preparation process of the composite ceramic core. First, use the core mold to evenly apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com