Horizontal movement type continuous electrolytic method and device of lead in regenerative lead-containing material

A technology of electrolytic regeneration and horizontal movement, which is applied in the direction of photographic technology, equipment, and photographic auxiliary technology, etc., which can solve the problems of affecting production efficiency, increasing the frequency of dredging, and excessive labor workload, so as to achieve continuous stability in the production process and reduce Cathode and anode spacing, conducive to the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

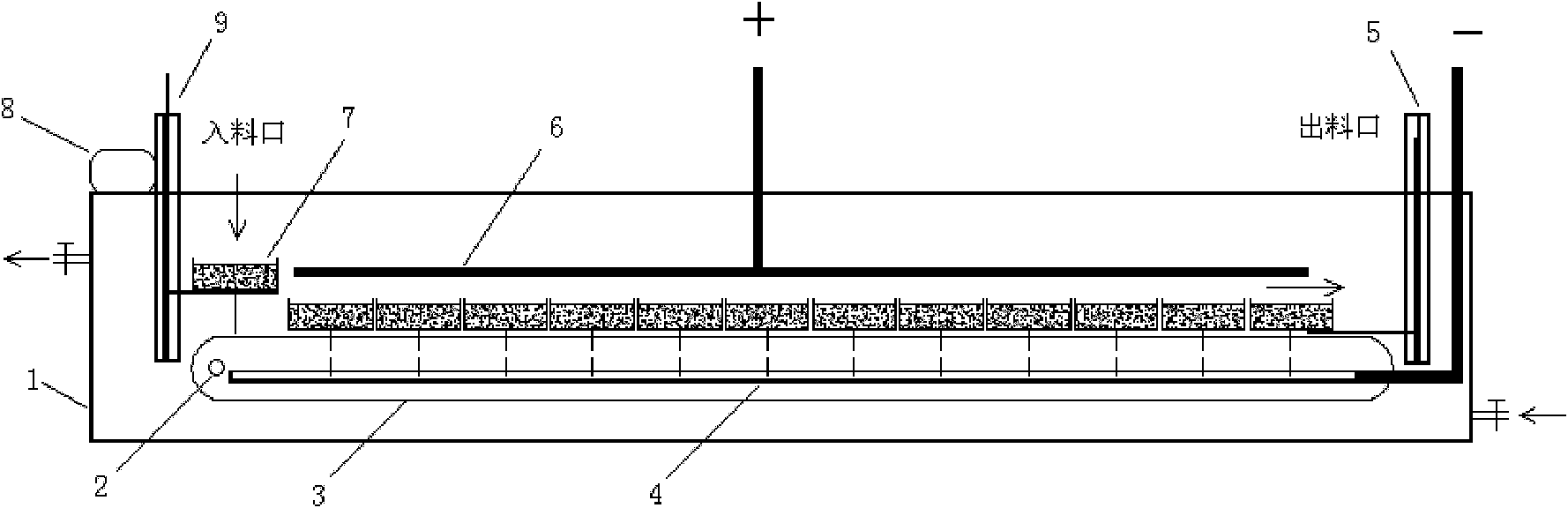

[0029] refer to Figure 1 ~ Figure 4 , a method for horizontally mobile continuous electrolytic regeneration of lead in lead-containing materials, using waste lead-acid batteries and lead-containing paste sludge produced in the production process of lead-acid batteries as raw materials for electrolytic regeneration, during the electrolysis process, alkaline electrolyte is used , the cathode and anode are arranged in a horizontal manner, and the lead-containing paste slurry to be treated is filled and coated on the cathode plate and moves horizontally continuously, and is electrolytically reduced to lead at the same time, realizing the continuous electrolytic regeneration of lead;

[0030] When the electrolysis is running, firstly fill the lead-containing paste evenly in the cathode plate, and then put the cathode plate into the electrolyte one by one from the feeding port through the feeding mechanism, place it on the transmission track, and drive the track drive through the dr...

Embodiment 2

[0036] refer to Figure 1 ~ Figure 4 A device for horizontally moving continuous electrolytic regeneration of lead in lead-containing materials, comprising an electrolytic cell 1 for placing alkaline electrolyte and a cathode disc 7 for placing lead-containing materials to be electrolyzed, the electrolytic cell 1 The lower part is provided with a transmission crawler 3, and the two ends of the transmission crawler 3 are set on the rotating shaft 2, and the rotating shaft 2 is connected to the driving device through transmission;

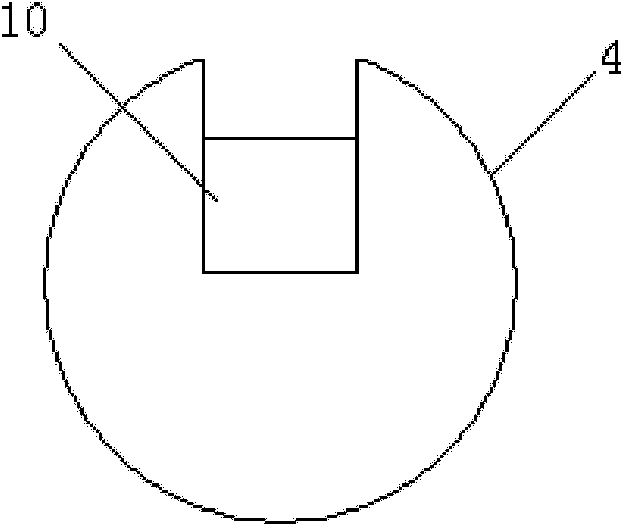

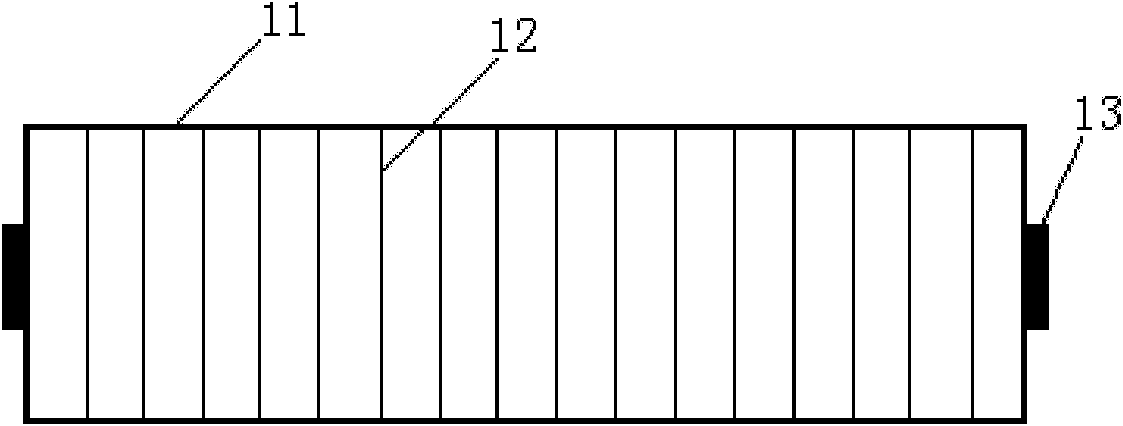

[0037]The double-row coaxial crawler 3 is horizontally arranged at the lower part of the electrolytic cell, and the shaft is driven by an external motor and a transmission system to move forward continuously; the cathode conductive copper bar 4 is arranged under the middle of the double-row crawler, and the upper part of the copper bar is provided with A horizontal notch for placing a liquid conductive agent; the cathode disk 7 is horizontally placed...

Embodiment 3

[0048] In this embodiment, the electrolysis test: take an appropriate amount of caustic soda solution with a mass concentration of 10% of the waste battery lead paste after pre-desulfurization, and adjust the apparent density of the lead paste to 2.5g / cm in a mixer 3 . After analysis, the material composition is PbO 2 Content is 34.1%, PbO content is 51.2%, sodium hydroxide 0.9%, water 13.8%, fill and smear this lead paste mud material on cathode disc then and weigh the quality of lead paste, make the filling in each cathode disc The amount of lead paste is 10kg.

[0049] Put the cathode disks on the crawler one by one through the lifting device of the feed port of the electrolytic cell, set the motor speed, and make the crawler continuously transport forward at a speed of 0.55m / h. When the cathode disk is conveyed to the discharge port of the electrolytic cell by the crawler, The cathode disk is separated from the power supply through the lifting device, and the electrolysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| power consumption | aaaaa | aaaaa |

| power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com