Adjustable damping combined vibration isolator

A technology of combining vibration isolators and adjusting damping, applied in vibration dampers, friction dampers, shock absorbers, etc., can solve the problems of single damping of vibration isolation devices, short life of vibration isolation components, and poor vibration isolation effect, etc. Achieve the effect of simple structure, low cost and easy rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

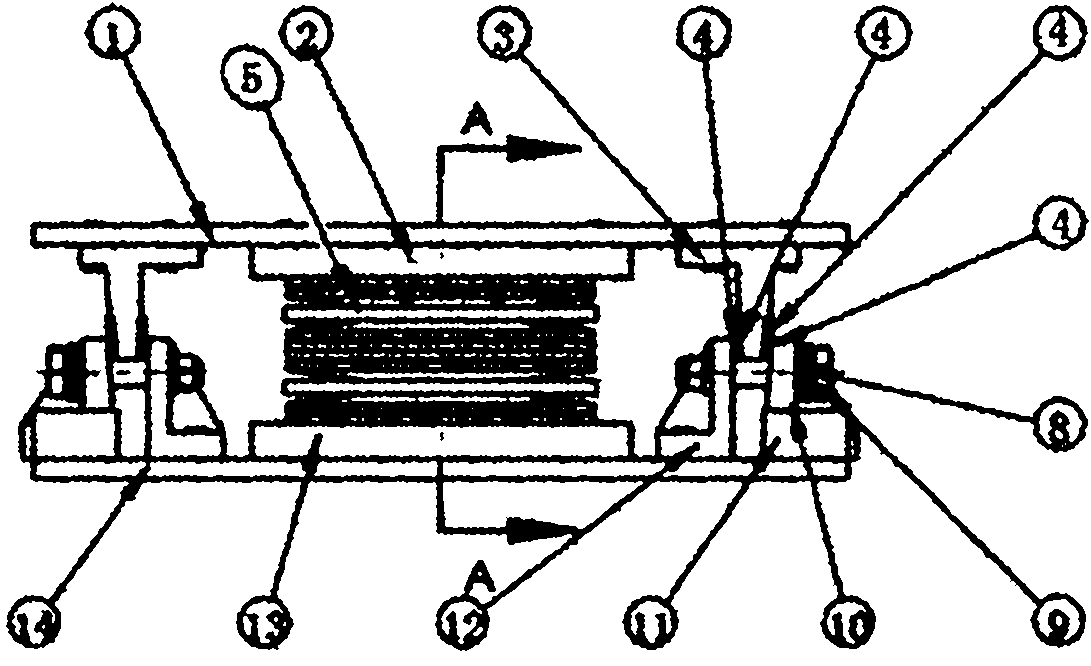

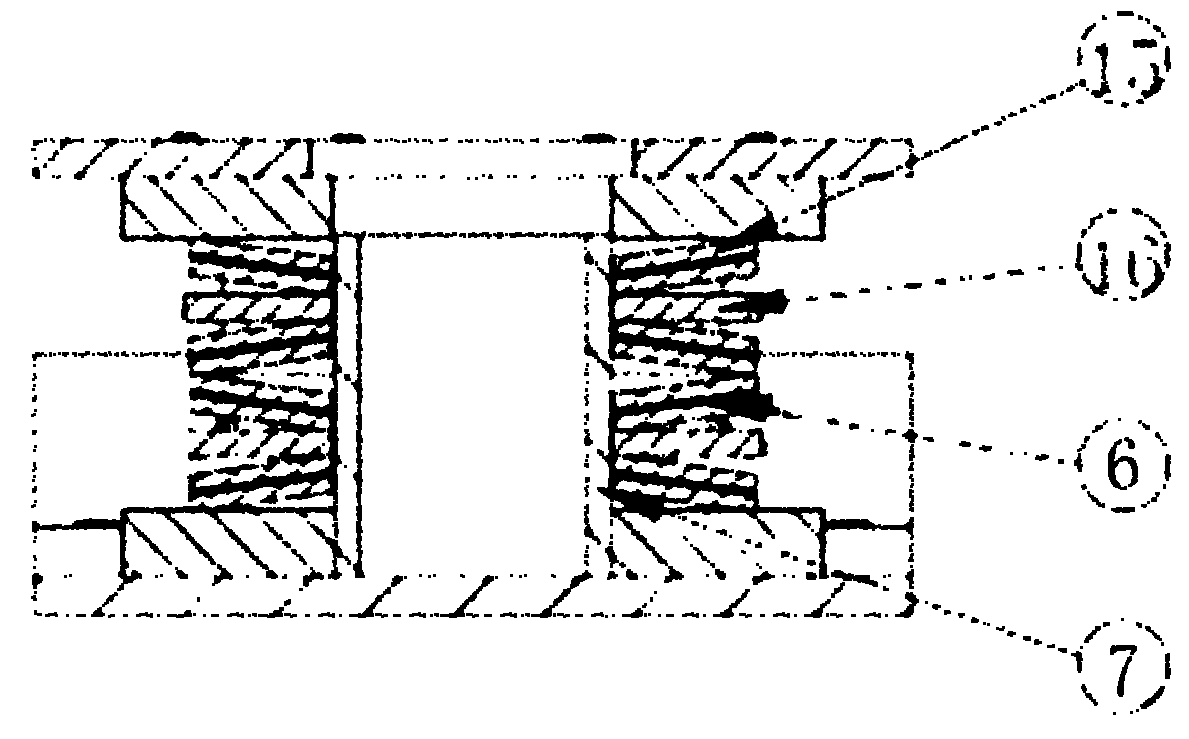

[0028] see figure 1 and figure 2 , the adjustable damping combination vibration isolator described in the present invention comprises an upper base plate 1, a lower base plate 14, an upper base 2, a lower base 13, a friction damper and a guide 7, and the upper base 2 is located on the upper base 1 and The vibration isolation elements are fixed on the upper base plate 1, the center of the upper base 2 and the upper base plate 1 has a through hole, the through hole can be movably matched with the outer side of the guide piece 7, the upper end surface of the upper base plate 1 and the upper end surface of the guide piece 7 There is a gap between them, and the gap is greater than the axial deformation of the vibration isolator; the lower base plate 14 fixes the lower base 13, and the guide 7 is fixedly connected with the lower base 13, which can be carried out by conventional means such as welding and screws. Fixed: one friction damper is fixed on at least one side of the upper ...

Embodiment 2

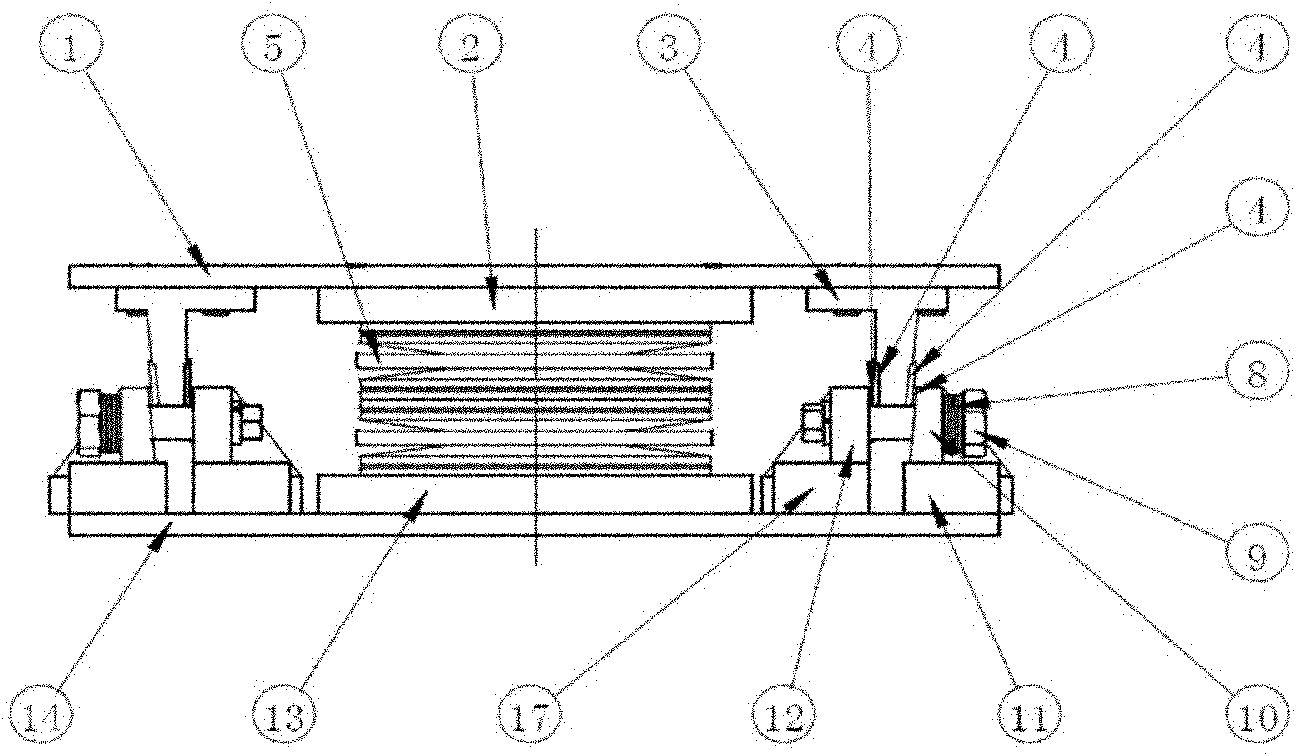

[0035] like image 3 As shown, compared with Embodiment 1, the difference is that a second pressure plate 17 is provided between the friction baffle plate 12 and the lower bottom plate, the second pressure plate 17 is installed on the lower bottom plate 14, and a guide rail is provided on the second pressure plate 17. The friction baffle plate 12 is laterally slidingly guided. The friction baffle 12 moves laterally along the guide rail. The friction damper with this structure can realize the two-way adjustment of the gap between the friction baffle 12 and the sliding baffle 10 , and compensate the assembly error of the friction plate 3 .

Embodiment 3

[0037] like Figure 4 As shown, compared with the second embodiment, the difference is that the contact surface of the friction plate 3 and the friction baffle 12 is an inclined surface contact. By adopting the friction damper with this structure, the two-way adjustment of the gap between the friction baffle 12 and the sliding baffle 10 can be realized. In addition, when the combined vibration isolator is subjected to an eccentric load, the structural friction baffle 12 and the sliding baffle 10 form a V-shaped gap, which can be adjusted slightly to ensure that the upper bottom plate 1 does not overturn.

[0038] Compared with Embodiment 1, both the friction baffle 12 and the sliding baffle 10 can slide laterally, and the V-shaped gap that can be adjusted in both directions is adopted, which improves the adjustment ability of the combined vibration isolator to the eccentric load, and can cope with multiple When two combined vibration isolators work at the same time, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com