Synthesis method of aluminum phosphate molecular sieve with three-dimensional crossed channels

A technology of aluminum phosphate molecular sieve and synthesis method, applied in molecular sieve and alkali exchange phosphate, bulk chemical production and other directions, can solve problems such as a large number of organic acid and alkali waste liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

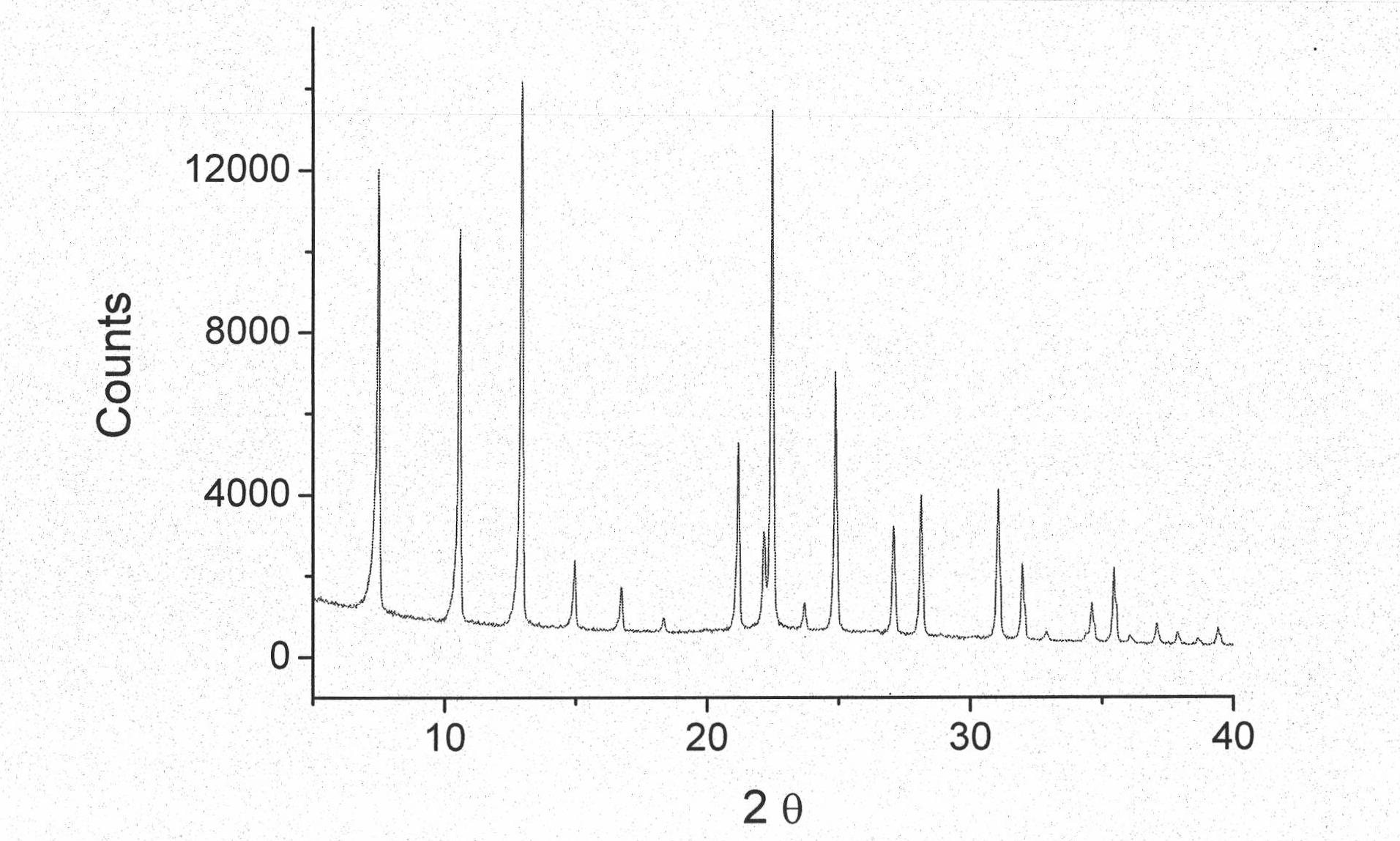

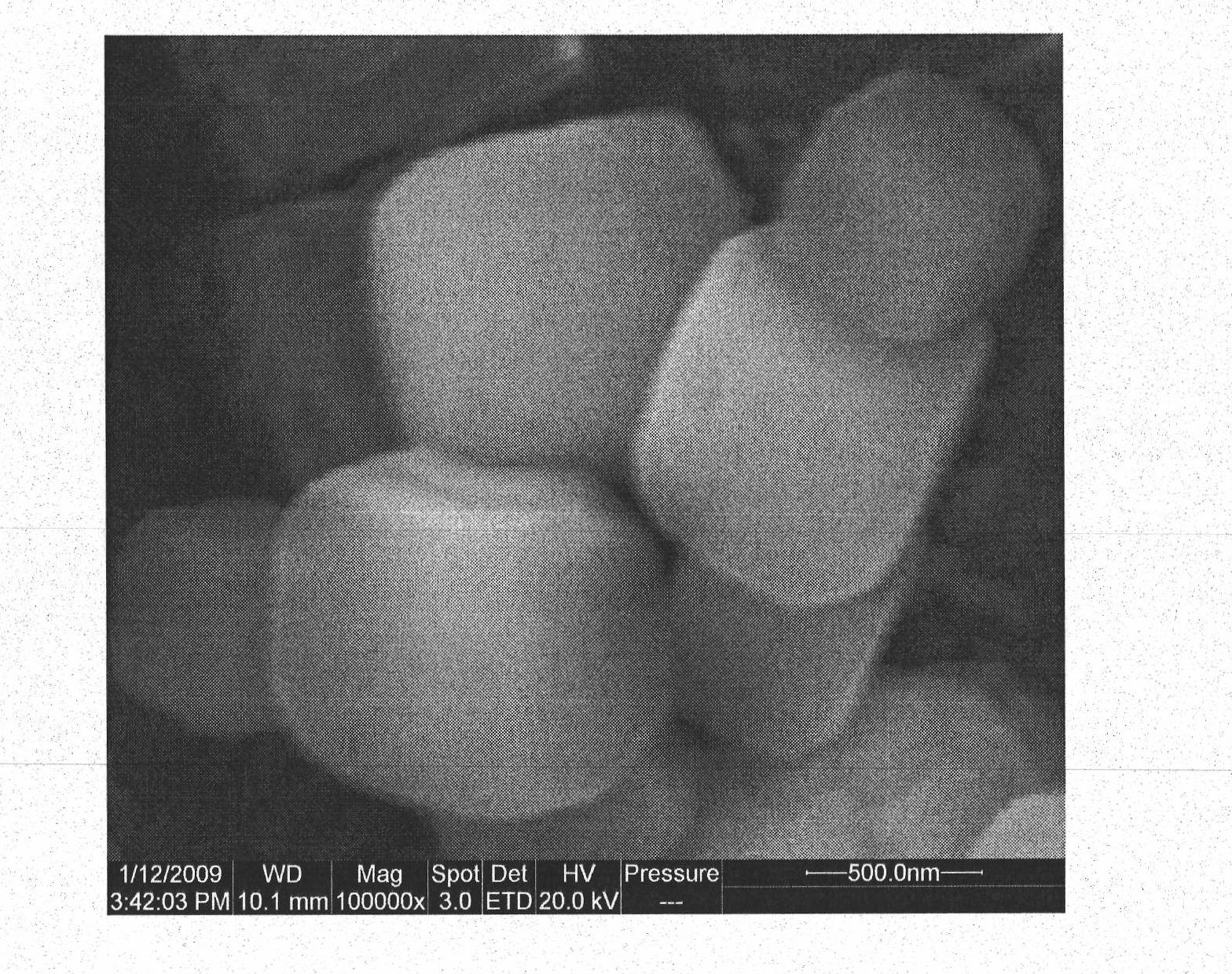

Embodiment 1

[0023] Add 30g of 1-butyl-3-methylimidazolium bromide ionic liquid into a 100ml beaker, raise the temperature to 120°C, stir magnetically and add 3.8g of aluminum isopropoxide evenly, drop 0.5g evenly with a mass concentration of 40% hydrofluoric acid, stirred for 2 hours until uniform, dropwise added 2.16g of phosphoric acid with a mass concentration of 85%, then uniformly added 2.1g of di-n-propylamine, continued to stir for 10 minutes, raised the temperature to 160°C, kept stirring for 12 hours, and then The reaction mixture was cooled to room temperature, 50 ml of deionized water was added, stirred, ultrasonically washed, the reactant was filtered to obtain a white solid powder, the washing was repeated three times, and the white was washed with 50 ml of acetone. The final white powder was dried in an oven at 110° C., and tested by XRD, the white powder was AlPO4-42 (LTA structure) molecular sieve, pure phase. The moisture and solvent in the filtrate after washing are evap...

Embodiment 2

[0025] Add 30g of 1-butyl-3-methylimidazolium bromide ionic liquid into a 100ml beaker, raise the temperature to 120°C, stir magnetically and add 3.8g of aluminum isopropoxide evenly, drop 0.5g evenly with a mass concentration of 40% hydrofluoric acid, stirred for 2 hours until uniform, dropwise added 3.34g of phosphoric acid with a mass concentration of 85%, then uniformly added 3.0g of triethylamine, continued to stir for 10 minutes, raised the temperature to 160°C, kept stirring for 24 hours, and then The reaction mixture was cooled to room temperature, 50 ml of deionized water was added, stirred, ultrasonically washed, the reactant was filtered to obtain a white solid powder, the washing was repeated three times, and the white was washed with 50 ml of acetone. The final white powder was dried in an oven at 110° C., and tested by XRD, the white powder was AlPO4-42 (LTA structure) molecular sieve, pure phase. The moisture and solvent in the filtrate after washing are evapora...

Embodiment 3

[0027] Add 25g of 1-butyl-3-methylimidazolium bromide ionic liquid into a 100ml beaker, heat up to 120°C, stir magnetically and add 3.8g of aluminum isopropoxide evenly, drop 0.5g evenly with a mass concentration of 40% hydrofluoric acid, stirred for 2 hours until uniform, dropwise added 2.16g of phosphoric acid with a mass concentration of 85%, then uniformly added 1.8g of n-butylamine, continued to stir for 10 minutes, raised the temperature to 160 ° C, kept stirring for 4 hours, and then The reaction mixture was cooled to room temperature, 50 ml of deionized water was added, stirred, ultrasonically washed, the reactant was filtered to obtain a white solid powder, the washing was repeated three times, and the white was washed with 50 ml of acetone. The final white powder was dried in an oven at 110° C., and tested by XRD, the white powder was AlPO4-42 (LTA structure) molecular sieve, pure phase. The moisture and solvent in the filtrate after washing are evaporated in a rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com