Polishing composition and polishing method using the same

A polishing composition, linear technology, applied in the direction of polishing composition containing abrasive, chemical instrument and method, record carrier manufacturing, etc., can solve unsatisfactory problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 15 and comparative example 1 to 18

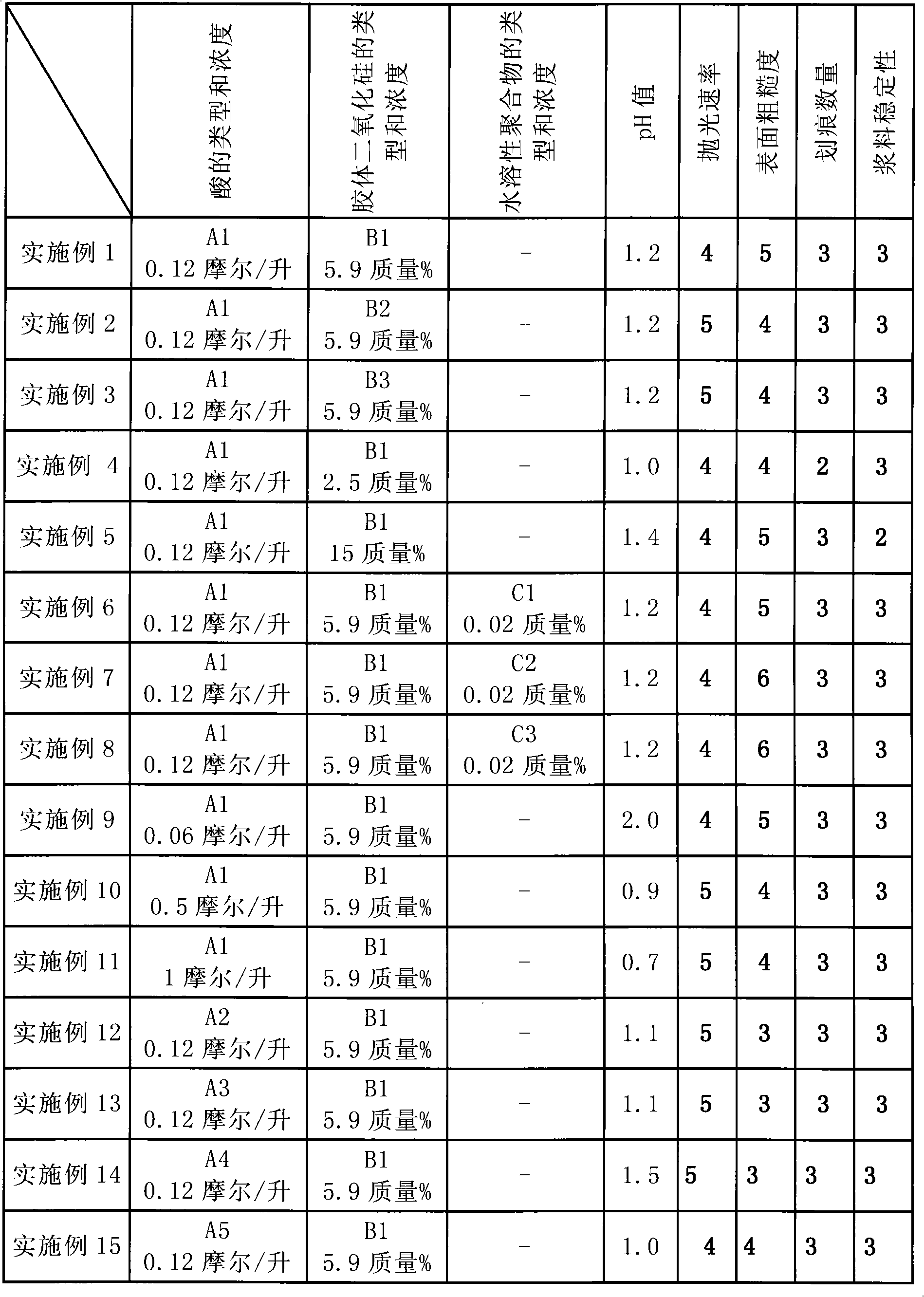

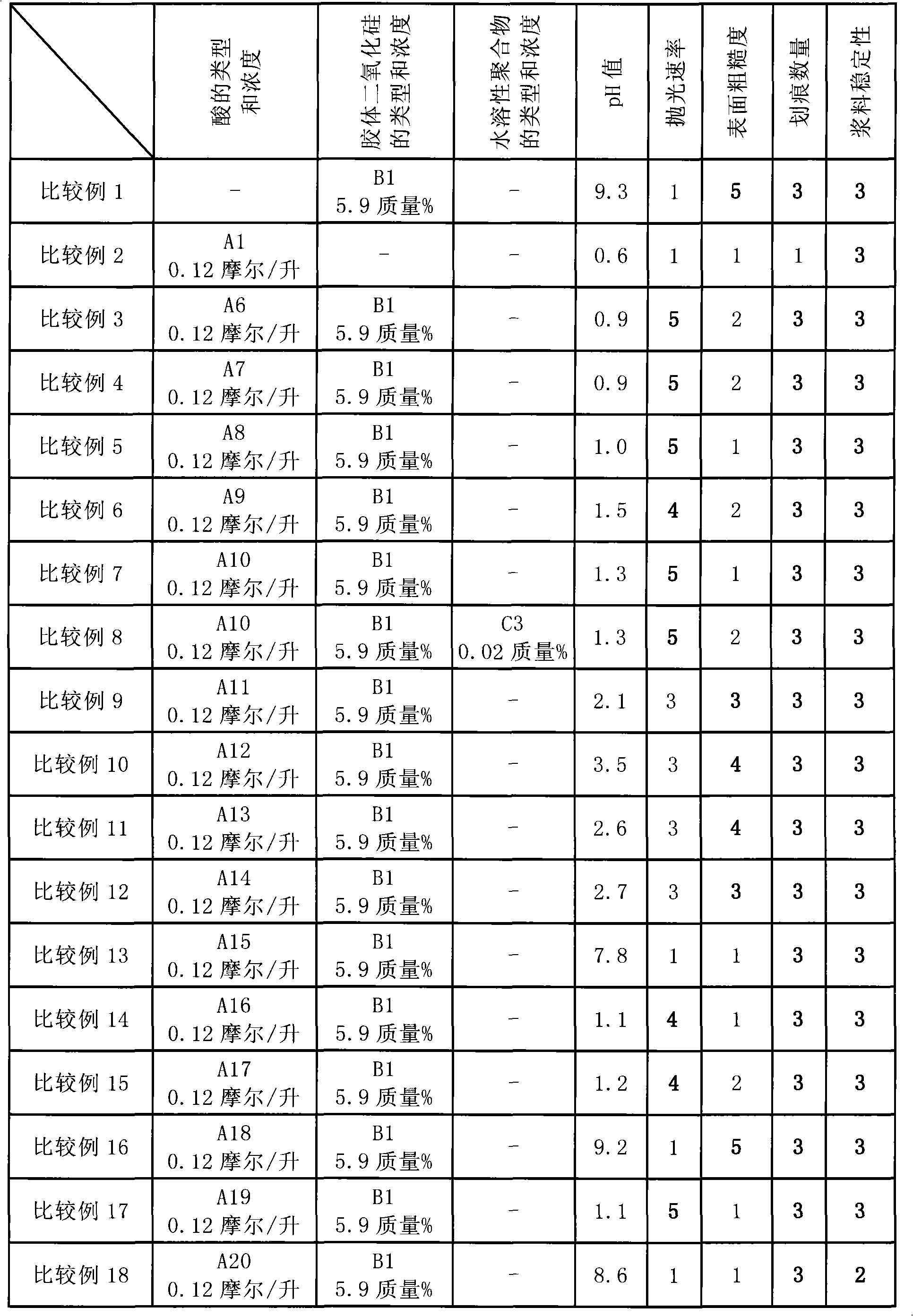

[0050] In Examples 1 to 15, the acid and colloidal silica were mixed with water, and optionally with a water-soluble polymer, to prepare polishing compositions. In Comparative Examples 1 to 18, an acid, colloidal silica, and a water-soluble polymer were mixed with water in appropriate proportions to prepare polishing compositions. The detailed information of the acid, colloidal silica, and water-soluble polymer in the polishing composition of each Example and Comparative Example and the results of measuring the pH value of the polishing composition of each Example and Comparative Example are shown in the table 1 and Table 2.

[0051] In the column titled "Acid Type and Concentration" of Tables 1 and 2,

[0052] A1 represents isethionic acid;

[0053] A2 represents sulfopropionic acid;

[0054] A3 represents sulfopropanediol;

[0055] A4 represents benzenesulfonic acid;

[0056] A5 represents ethanedisulfonic acid;

[0057] A6 represents sulfuric acid;

[0058] A7 repres...

Embodiment 21 to 24 and comparative example 21 to 24

[0092] In Examples 21 to 24, an acid and colloidal silica were mixed with water, optionally together with a pH adjuster, to prepare a polishing composition. In Comparative Examples 21 to 24, colloidal silica was mixed with water, and optionally with a pH adjuster, to prepare polishing compositions. Table 4 shows details of the acid, colloidal silica, and pH adjuster in the polishing compositions of Examples and Comparative Examples, and the measurement results of the pH of the polishing compositions of Examples and Comparative Examples.

[0093] In Table 4, A1 in the column titled "Type and Concentration of Acid" represents isethionic acid; B4 in the column titled "Type and Concentration of Colloidal Silica" represents those having an average primary particle size of 35 nm and colloidal silica with an average secondary particle diameter of 66 nm; and, C1 in the column named "pH adjuster" represents nitric acid, and C2 in the column named "pH adjuster" represents ammonia.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com