Preparation method of lamellar gamma-phase nano aluminum oxide

A nano-alumina, flaky technology, applied in the field of preparation of flaky γ-phase nano-alumina, can solve the problems of complex process, high reaction temperature, low efficiency, etc., achieve simple preparation process, increase specific surface area, energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

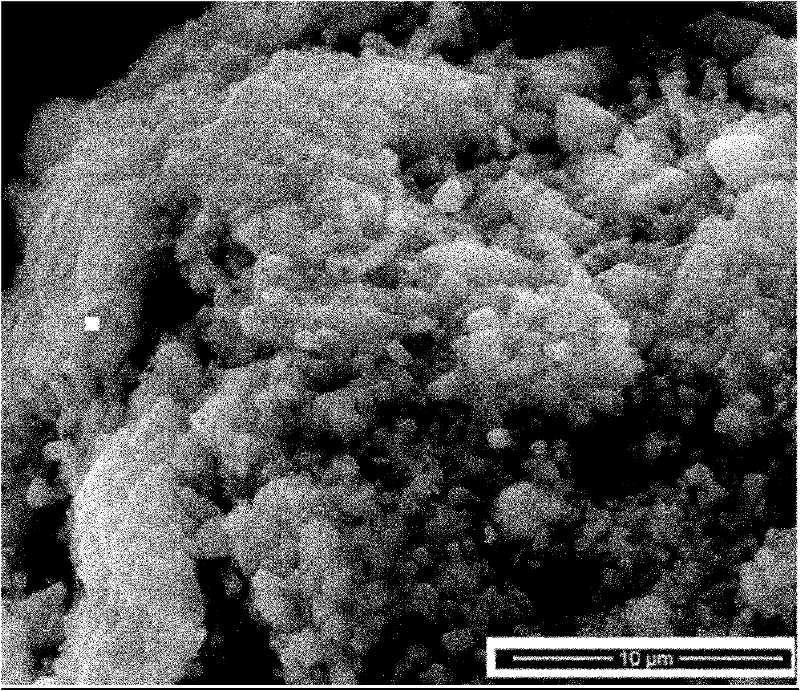

[0025] A. Put 100g of aluminum powder material with a purity greater than 99.5% and a particle size of 95-100 μm into a rolling vibratory mill with a volume of 2.5 liters and a power of 0.12 kW for grinding for 2 hours, so that the aluminum powder can be finely processed at the same time form high-energy metastable states, such as figure 1 shown;

[0026] B. Mix the prepared high-energy metastable aluminum powder with tap water in a ratio of 1:10 by weight, and ultrasonically vibrate for 2 hours in an ultrasonic oscillator with a power of 99 Hz to prepare white milky Al(OH) colloid;

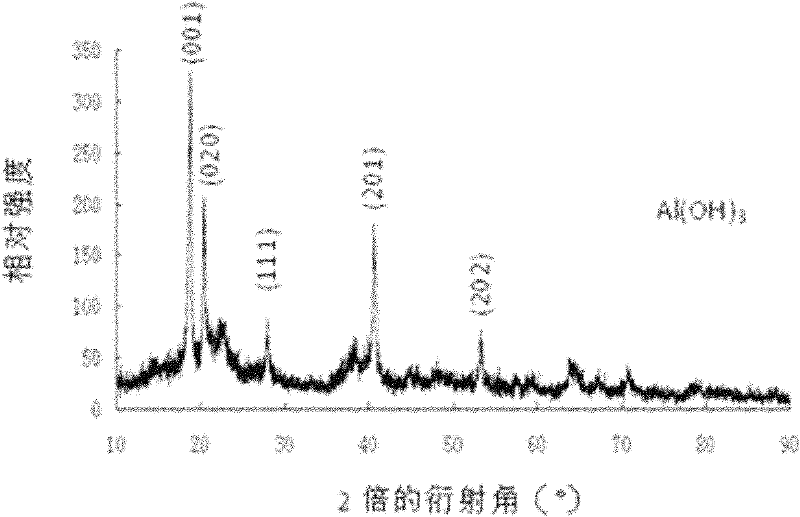

[0027] C. Put the white milky Al(OH) 3 The colloid was directly put into a constant temperature drying oven, and dried at 80°C for 6 hours to obtain Al(OH) 3 powder, whose crystal structure is diffracted as figure 2 shown;

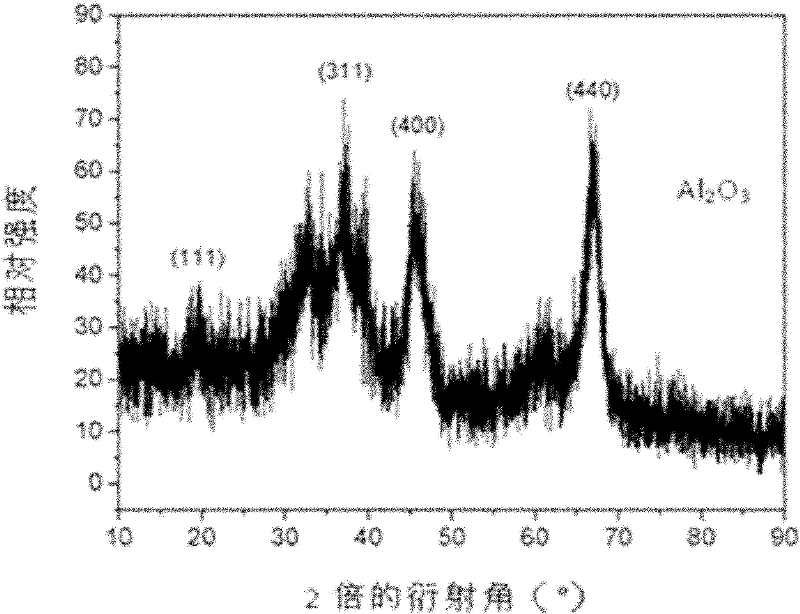

[0028] D. Put the powder into a box-type resistance furnace to dry at 160°C, and dry at a constant temperature for 4 hours to obtain γ-phase sheet-shaped nano-alumina. T...

Embodiment 2

[0030] A. Put 100g of aluminum powder material with a purity greater than 99.5% and a particle size of 95-100 μm into a rolling vibration mill with a volume of 2.5 liters and a power of 0.12 kW for grinding for 2 hours, so that the aluminum powder is finely processed at the same time form high-energy metastable states, such as figure 1 shown;

[0031] B. Mix the prepared high-energy metastable aluminum powder with tap water in a weight ratio of 1:10, and ultrasonically vibrate for 2 hours in an ultrasonic oscillator with a power of 99 Hz to prepare white milky Al(OH) 3 colloid;

[0032] C. Put the white milky Al(OH) 3 The colloid was directly put into a constant temperature drying oven, and dried at 80°C for 6 hours to obtain Al(OH) 3 powder, whose crystal structure is diffracted as figure 2 shown;

[0033] D. Put the powder into a box-type resistance furnace to dry at 180°C, and dry at a constant temperature for 4 hours to obtain γ-phase sheet-shaped nano-alumina, whose...

Embodiment 3

[0035] A. Put 100g of aluminum powder material with a purity greater than 99.5% and a particle size of 95-100 μm into the equipment with a volume of 2 figure 1 Shown; 2.5 liters, the power is 0.12kW rolling vibratory mill grinding 2h in the barrel, so that the aluminum powder forms a high-energy metastable state while fine processing,

[0036]B. Mix the prepared high-energy metastable aluminum powder with tap water in a ratio of 1:10 by weight, and ultrasonically vibrate for 4 hours in an ultrasonic oscillator with a power of 70 Hz to prepare white milky Al(OH) colloid;

[0037] C. Put the white milky Al(OH) 3 The colloid was directly put into a constant temperature drying oven, and dried at 80°C for 6 hours to obtain Al(OH) 3 powder, whose crystal structure is diffracted as figure 2 shown;

[0038] D. Put the powder into a box-type resistance furnace to dry at 210°C, and dry at a constant temperature for 4 hours to obtain γ-phase sheet-shaped nano-alumina, whose crystal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com