Clathrate of paeonol and preparation method and quality detection method thereof

A paeonol and clathrate technology, which is applied in the field of clathrates of active ingredients in traditional Chinese medicine, can solve the problems of unfavorable large-scale industrial production, long time spent, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

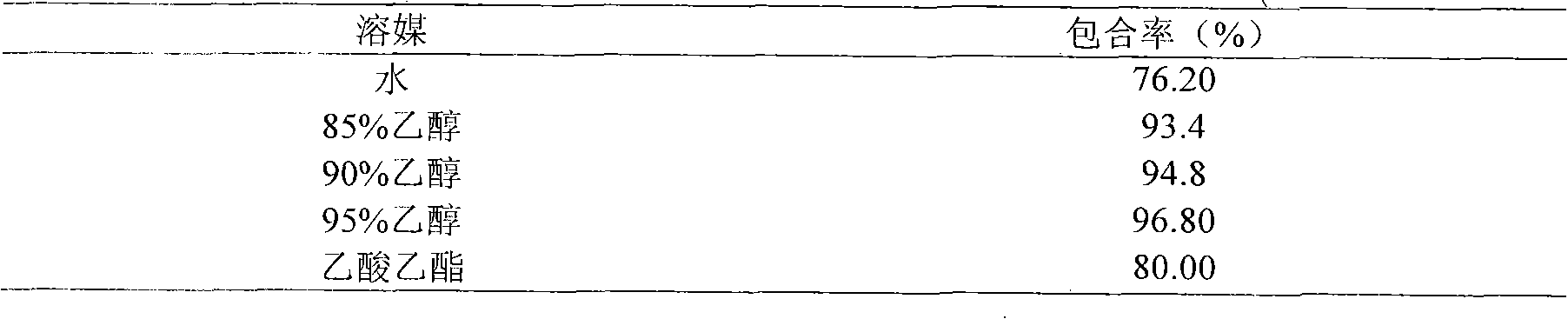

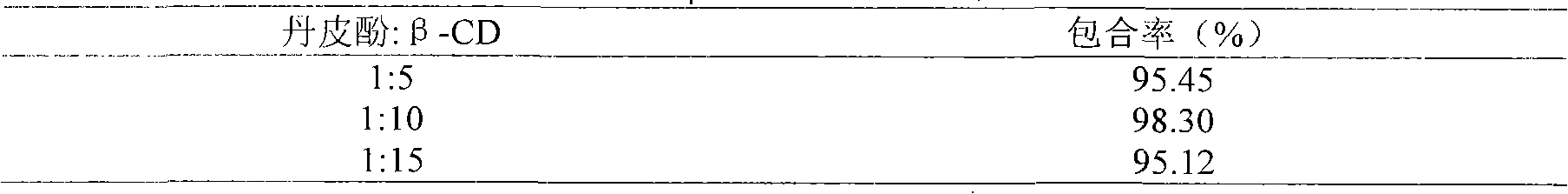

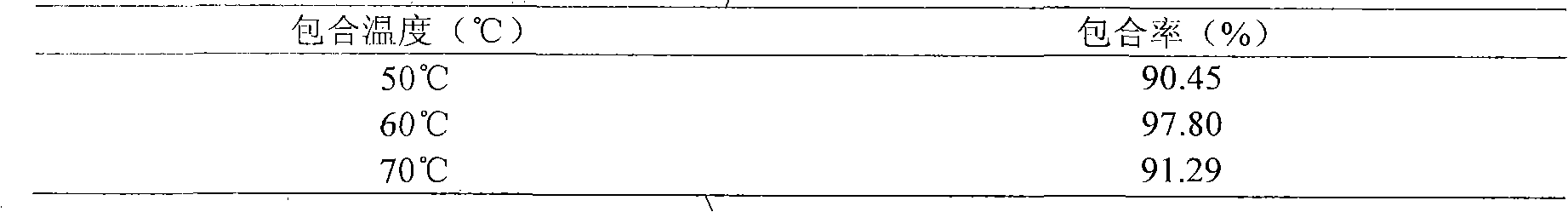

[0141] 1. Preparation of paeonol inclusion compound:

[0142] Take β-cyclodextrin of 6 times the amount of paeonol, add 2 times the amount of water and stir well, heat to 55°C; take paeonol and add 4 times the amount of 85% ethanol, heat to dissolve and pour into β-cyclodextrin Grind in the fine solution for 15 minutes with a colloid mill, discharge the material, place it at room temperature for 14 hours, filter it with suction, and dry it at 40°C to obtain paeonol inclusion compound.

[0143] 2. Detection of paeonol inclusion complex

[0144] (1) Chromatographic conditions: gas chromatograph; capillary chromatographic column with 5% diphenyl-95% dimethylsilane copolymer as stationary phase; inlet temperature: 230°C; detector temperature (FID): 240°C ;Split ratio: 25:1; Temperature program: initial temperature 80°C, keep for 2min, increase to 160°C at 20°C per minute, keep for 6min, measure; carrier gas: nitrogen, flow rate: 1.0ml / min; injection: 2μl ; The number of theoreti...

Embodiment 2

[0150] 1. Preparation of paeonol inclusion compound:

[0151] Take β-cyclodextrin of 10 times the amount of paeonol, add 2.7 times the amount of purified water and stir well, heat to 60°C; take paeonol and add 5 times the amount of 95% ethanol, heat to dissolve and pour into β-cyclodextrin Grind in dextrin solution for 20 minutes with a colloid mill, discharge, stand at room temperature for 24 hours, filter with suction, and dry at 50°C to obtain paeonol inclusion compound. Detection of paeonol inclusion complex

[0152] (1) Chromatographic conditions: gas chromatograph; capillary chromatographic column with 5% diphenyl-95% dimethylsilane copolymer as stationary phase; inlet temperature: 220°C; detector temperature (FID): 230°C ; Split ratio: 20:1; Temperature program: initial temperature 80°C, keep 2min, increase to 160°C at 20°C per minute, keep 6min, measure; carrier gas: nitrogen, flow rate: 1.0ml / min; sample injection: 5μl ; The number of theoretical plates is calculat...

Embodiment 3

[0158] 1. Preparation of paeonol inclusion compound:

[0159] Take β-cyclodextrin with 14 times the amount of paeonol, add 4 times the amount of water and stir well, heat to 70°C; take paeonol and add 7 times the amount of 90% ethanol, heat to dissolve and pour into β-cyclodextrin Grind in the fine solution for 30 minutes with a colloid mill, discharge the material, place it at room temperature for 24 hours, filter it with suction, and dry it at 60°C to obtain paeonol inclusion compound.

[0160] 2. Detection of paeonol inclusion complex

[0161] (1) Chromatographic conditions: gas chromatograph; capillary chromatographic column with 5% diphenyl-95% dimethylsilane copolymer as stationary phase; inlet temperature: 240°C; detector temperature (FID): 250°C ;Split ratio: 25:1; Temperature program: initial temperature 80°C, keep for 2min, increase to 160°C at 20°C per minute, keep for 6min, measure; carrier gas: nitrogen, flow rate: 1.0ml / min; injection: 10μl ; The number of theo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com