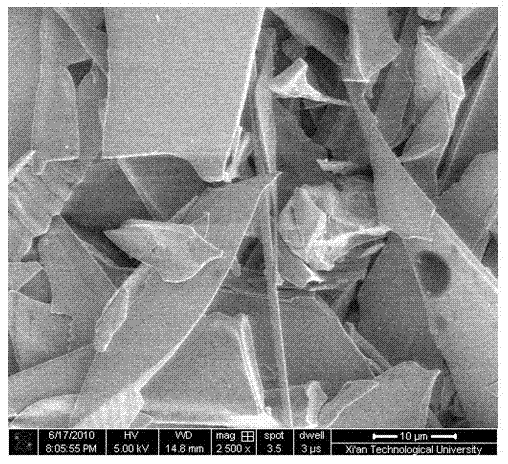

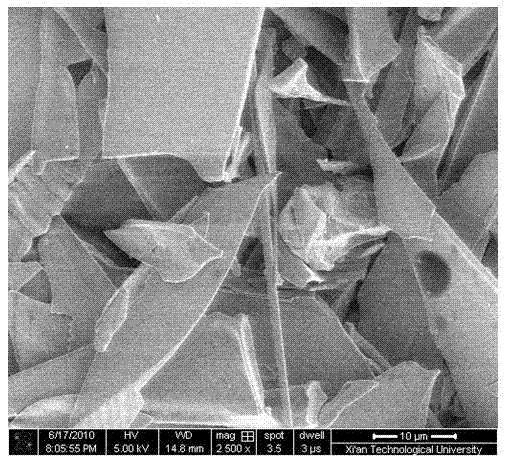

Method for fast preparing micron-level lamellar barium titanate powder

A micron-scale, flaky technology, applied in chemical instruments and methods, nanotechnology, titanium compounds, etc., can solve the problems of low production efficiency, cumbersome process, difficult process control, etc., and achieve shortened production cycle and obvious flaky characteristics , The effect of reducing the process link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 : A rapid preparation of micron-scale flake BaTiO 3 The method of powder, comprises the following steps successively:

[0028] The first step (1) will BaCO 3 Powder, TiO 2Powder and KF powder were mixed at a molar ratio of 1:1:49, using a polytetrafluoroethylene ball mill tank, agate balls, and anhydrous ethanol medium during the mixing process, and ball milled for 6 hours, then dried at 60-75°C for use; (2 ) Put the mixture into a platinum crucible, heat it in an ordinary crucible resistance furnace until it melts to obtain a melt, and keep the melt at 950±20°C for 2 hours for use; (3) Cool the melt until it solidifies to obtain a solidified structure;

[0029] The second step first place the coagulated tissue obtained in the first step in boiling deionized water for ultrasonic cleaning, pour off the clear liquid after standing still, and do this several times; then add NH 4 Cl dilute solution, perform ultrasonic cleaning, pour off the clear liquid after...

Embodiment 2

[0030] Example 2 : A rapid preparation of micron-scale flake BaTiO 3 The method of powder, comprises the following steps successively:

[0031] The first step (1) will BaCO 3 Powder, TiO 2 Powder and KF powder are mixed at a molar ratio of 1:1:62, and the mixing process uses a polytetrafluoroethylene ball mill jar, agate balls, and anhydrous ethanol medium, and the ball mill is mixed for 6 hours, and dried at 60-75°C for use; (2 ) Put the mixture into a platinum crucible, heat it in an ordinary crucible resistance furnace until it melts to obtain a melt, and keep the melt at 1030±20°C for 1.5 hours for use; (3) Cool the melt until it solidifies to obtain a solidified structure;

[0032] The second step first place the coagulated tissue obtained in the first step in boiling deionized water for ultrasonic cleaning, pour off the clear liquid after standing still, and do this several times; then add NH 4 Cl dilute solution, perform ultrasonic cleaning, pour off the clear liqu...

Embodiment 3

[0033] Example 3 : A rapid preparation of micron-scale flake BaTiO 3 The method of powder, comprises the following steps successively:

[0034] The first step (1) will BaCO 3 Powder, TiO 2 Powder and KF powder were mixed at a molar ratio of 1:1:41. During the mixing process, a polytetrafluoroethylene ball mill tank, agate balls, and anhydrous ethanol medium were used for ball milling and mixing for 6 hours, and dried at 60-75°C for use; (2 ) Put the mixture into a platinum crucible, heat it in an ordinary crucible resistance furnace until it melts to obtain a melt, and keep the melt at 880±20°C for 4 hours for use; (3) Cool the melt until it solidifies to obtain a solidified structure;

[0035] The second step first place the coagulated tissue obtained in the first step in boiling deionized water for ultrasonic cleaning, pour off the clear liquid after standing still, and do this several times; then add NH 4 Cl dilute solution, perform ultrasonic cleaning, pour off the cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com