Molten bath and method for recycling thermosetting epoxy resin or composite material by using same

A composite material and hydroxide technology, which is applied in the field of molten bath and used to recycle thermosetting epoxy resin and its composite material, can solve the problems of expensive solvent, high decomposition temperature, increase processing cost, etc., and achieve low processing efficiency. , to achieve separation, easy to enlarge the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

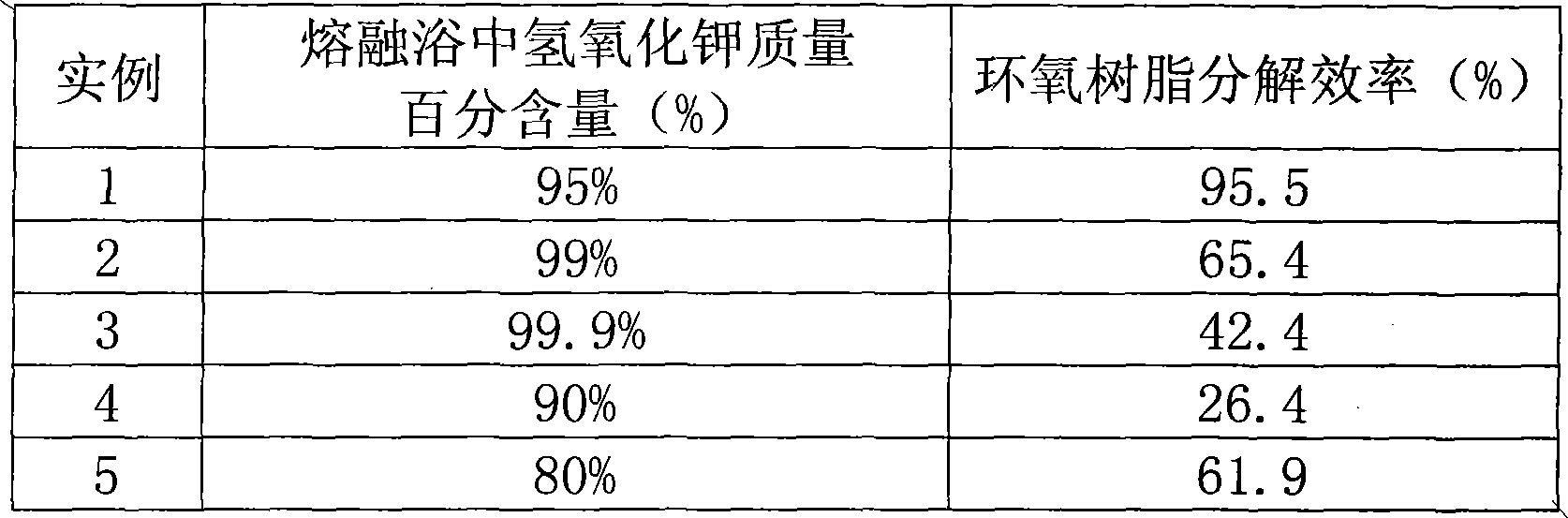

Embodiment 1

[0011] Epoxy resin (EP) matrix is bisphenol A diglycidyl ether type epoxy resin (epoxy value 0.48-0.54) in the present embodiment, and methyltetrahydrophthalic anhydride (MeTHPA) is curing agent, and benzyl Dimethylamine (BDMA) is an accelerator, and its weight ratio is EP / MeTHPA / BDMA=100:80:1. The curing conditions are 2 hours at 100°C and 5 hours at 150°C. The size of the epoxy resin spline is 1cm× 4cm×0.4cm, the weight percentage of epoxy resin or its composite material and molten bath material is 1:20.

[0012] Add potassium hydroxide and sodium nitrite into a stainless steel reactor, the mass percentage of potassium hydroxide in the mixture is 95%, and heat to 300° C. to prepare a molten bath. Put in cured epoxy resin, and the reaction time is 10 minutes. After finishing the reaction, unreacted epoxy resin is taken out, washed with water and dried, and then weighed. The results are shown in Table 1.

Embodiment 2

[0014] The difference between this example and Example 1 is that the mass percentage of potassium hydroxide in the mixture is 99%. The results are shown in Table 1.

Embodiment 3

[0016] The difference between this example and Example 1 is that the mass percentage of potassium hydroxide in the mixture is 99.9%. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com