Integrated method for thin oil blending, viscosity reduction, extraction and transportation of thickened oil

A heavy oil and viscosity reduction technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of high energy consumption and operating temperature, insufficient supply of thin oil, and reduce the quality of thin oil. Reduced oil consumption, maximized solvent utilization efficiency, and good viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

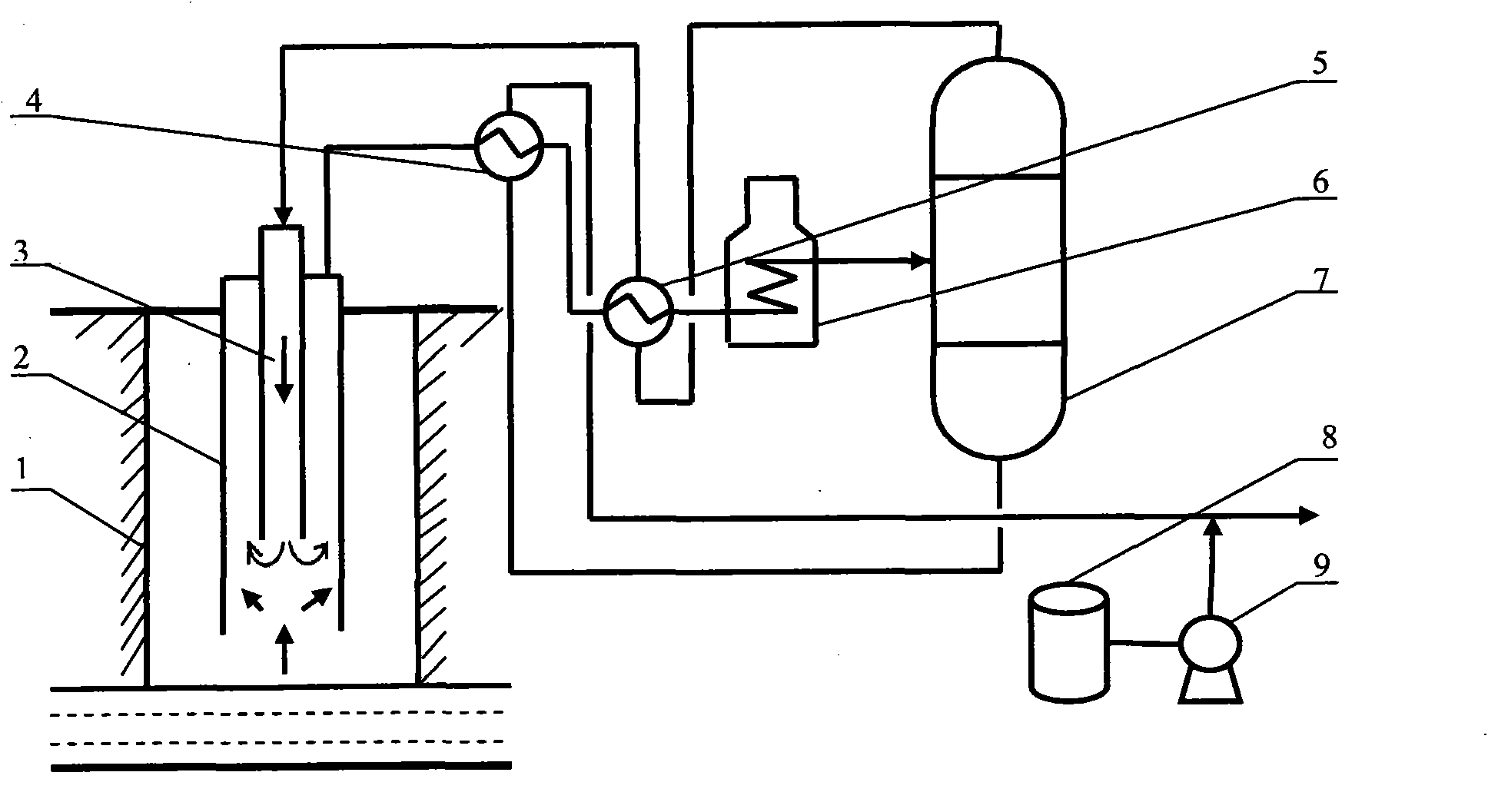

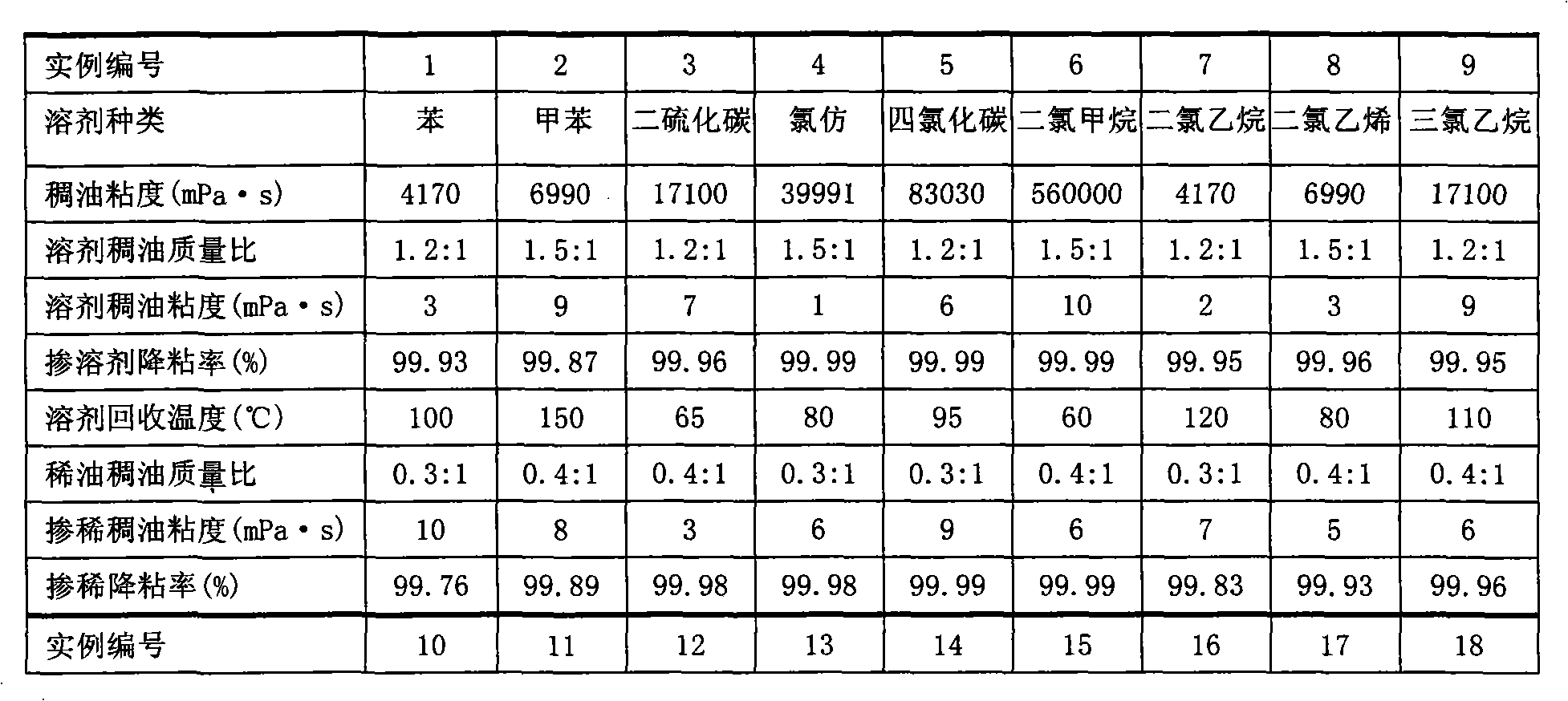

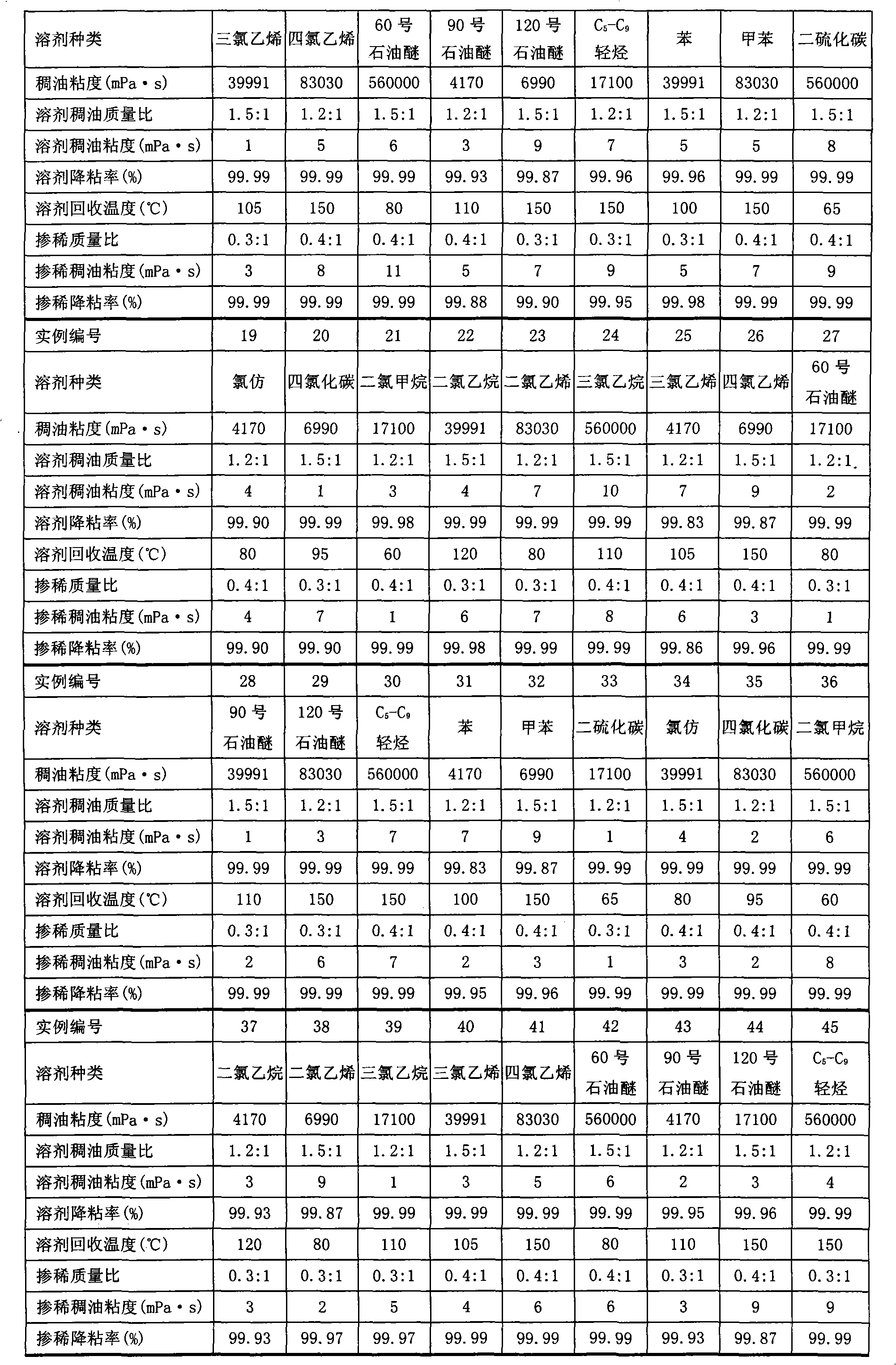

[0017] 1. According to the organic solvent and heavy oil mass ratio of 1.0 to 1.5:1, the solvent is mixed into the tubing 2 in the wellbore through the hollow sucker rod 3. The solvent and the heavy oil are automatically mixed evenly during the flow process, so that the solvent is mixed The viscosity of heavy oil (solvent heavy oil for short) meets the requirements of heavy oil flow in the wellbore and pipeline transportation between well stations. Take samples to determine the viscosity of the solvent heavy oil and calculate the viscosity reduction rate.

[0018] 2. The solvent heavy oil is transported through the pipeline and enters the thinning and viscosity reducing device. The thick solvent oil passes through the heat exchanger A4, the heat exchanger B5 and the heating furnace 6 to exchange heat to 50~150℃, and then enters the distillation tower 7, and is separated in the distillation tower 7, and the solvent at the top of the tower is recovered and passed through the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com