Method for preparing chalcopyrite solar cell light absorption layer and cell thereof

A technology for solar cells and light absorbing layers, which is applied in the manufacturing of circuits, electrical components, and final products, etc., can solve the problems of insufficient uniformity of the light absorbing layer, and achieve the effects of single crystal phase, good crystallinity, and improved uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

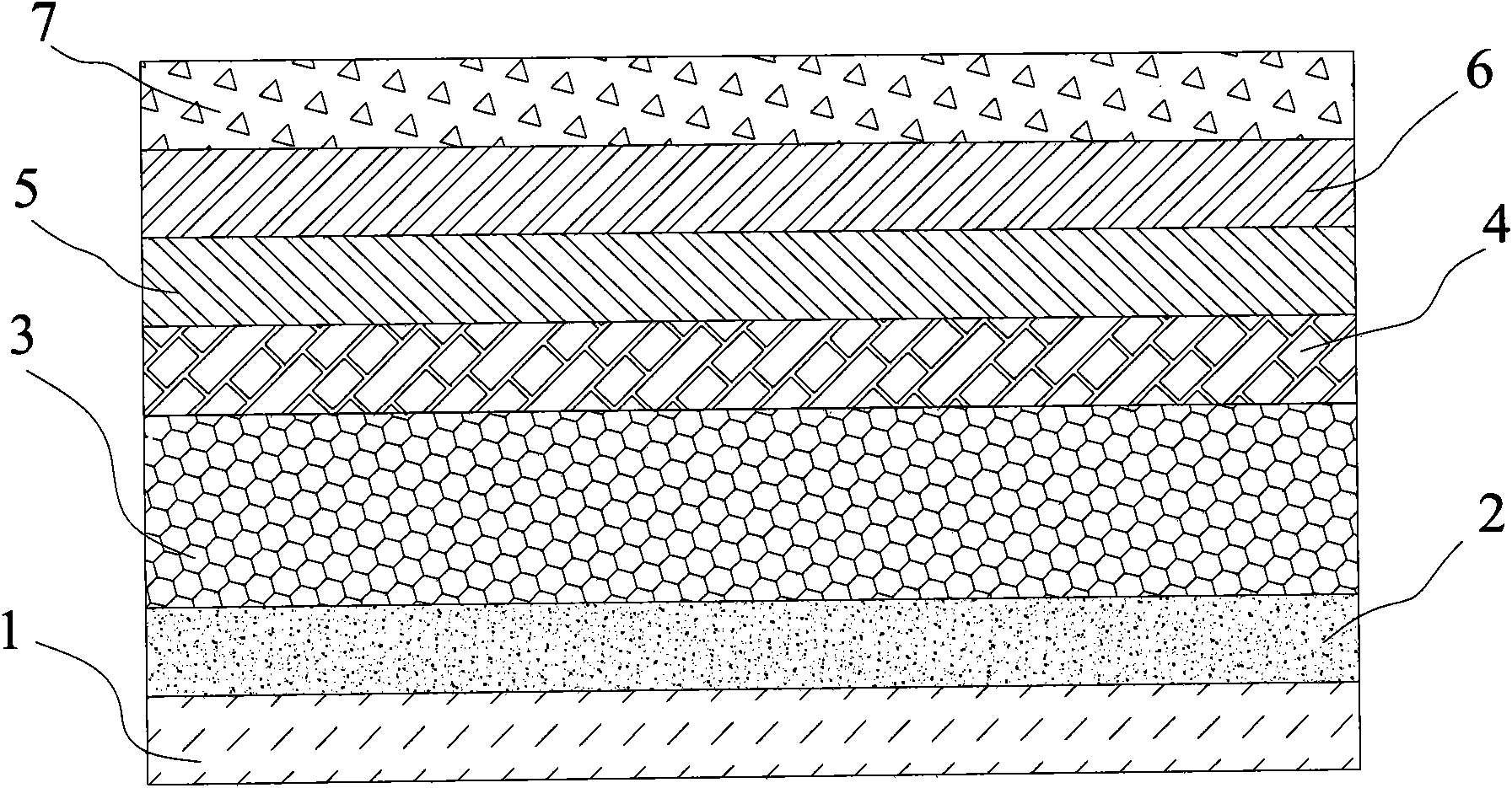

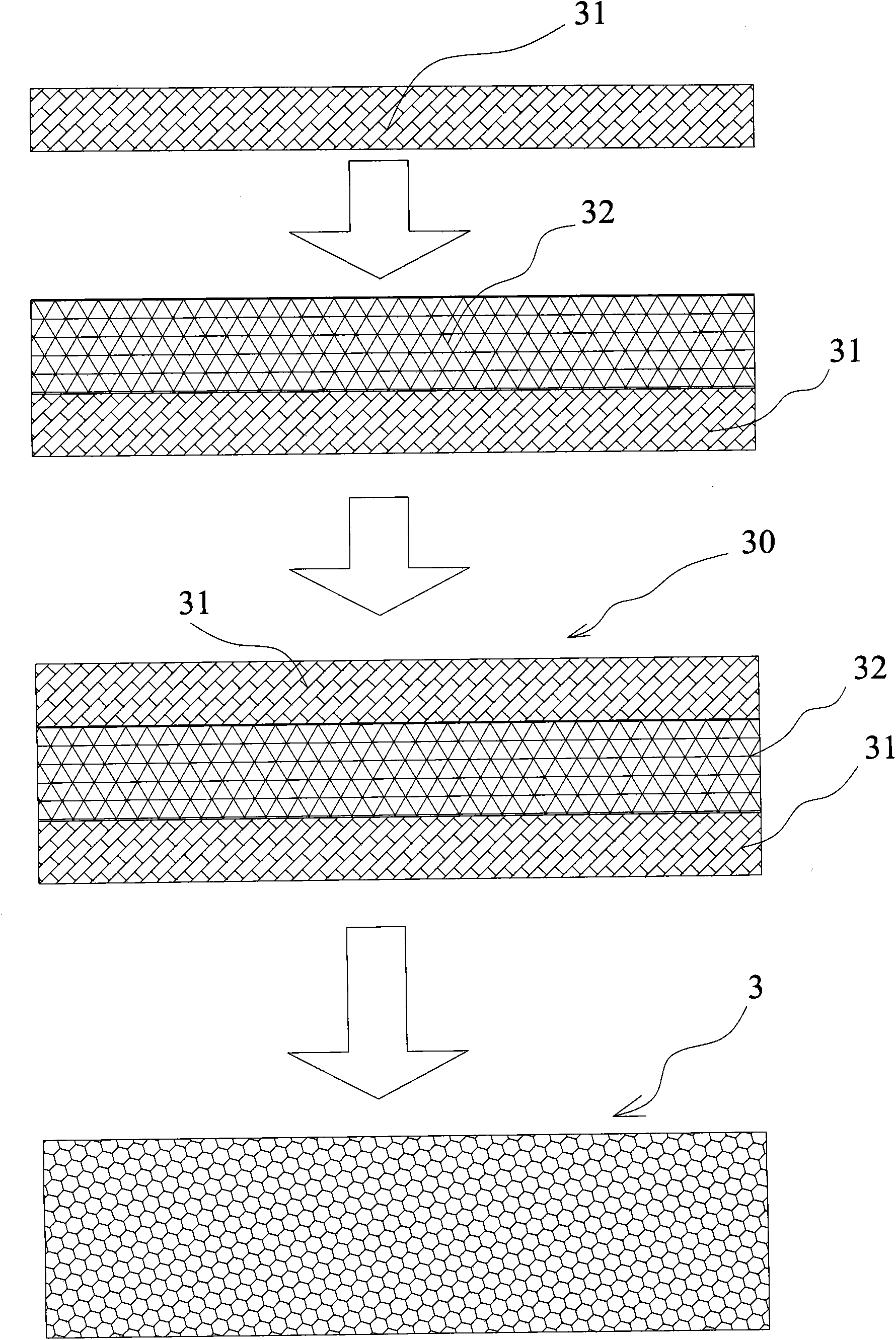

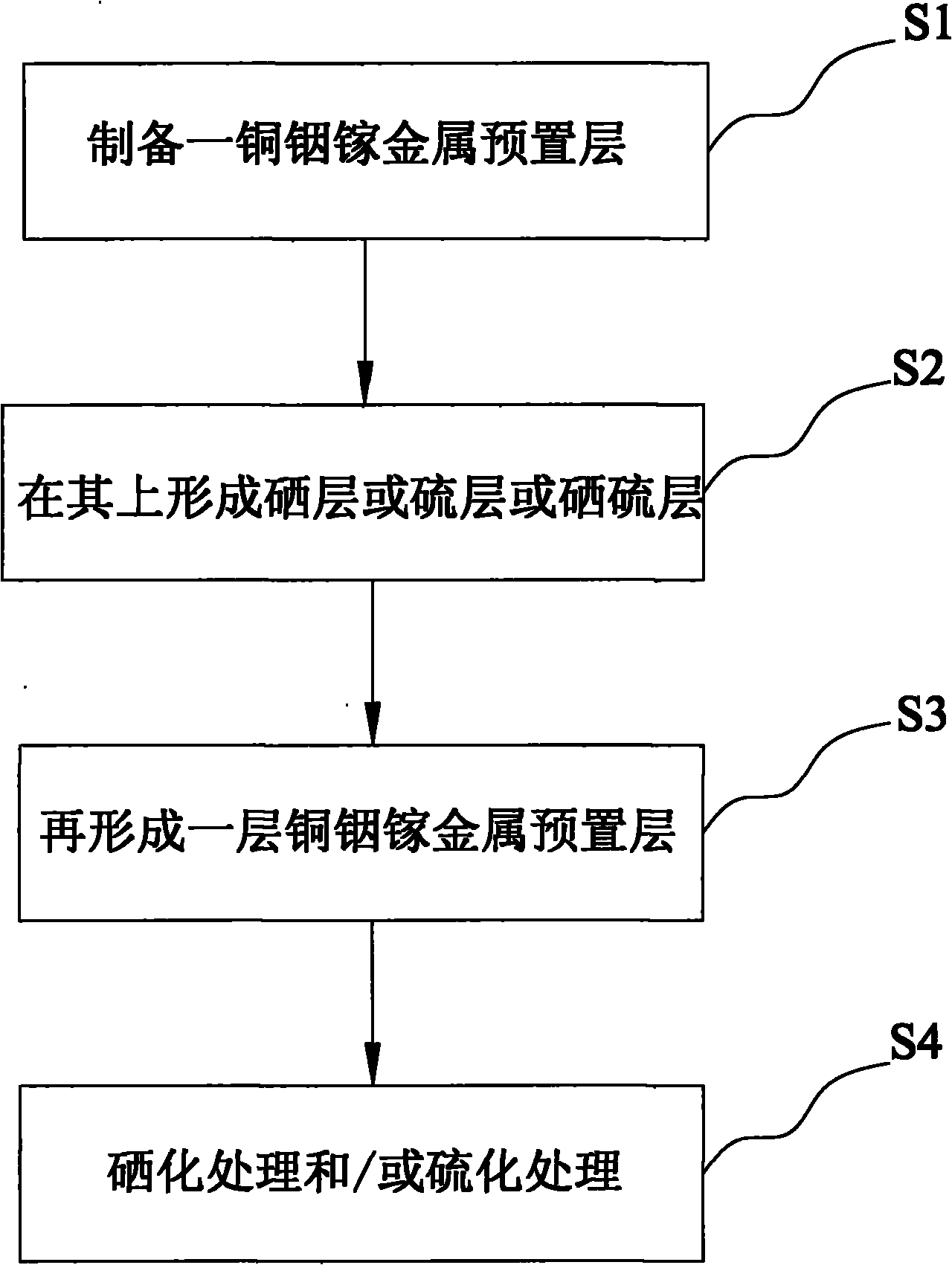

[0036] The preparation method of the light absorption layer of chalcopyrite-type solar cell, the preparation process is as follows image 3 As shown, you can visually refer to the diagram of its preparation method, such as figure 2 As shown, including the following steps:

[0037] S1: Preparation of a metal pre-layer 31; its material is copper indium or copper indium gallium, copper indium gallium is actually only part of gallium replaced part of indium, and its production method is generally to pass directly on the substrate deposited with the metal back electrode The magnetron sputtering method deposits a layer of copper indium or copper indium gallium. This metal pre-layer is also called a precursor film in the art.

[0038] When the material of the metal pre-layer 31 is copper indium, the copper indium metal pre-layer 31 is generally prepared by sputtering a copper indium target material to deposit a copper indium film. The selenized chalcopyrite-type solar cell is called cop...

Embodiment 1

[0051] The method for preparing a copper indium gallium selenium solar cell in this example: sputtering and depositing a 1.0 μm Mo back electrode layer on the soda lime glass, and then depositing a 0.5 μm CuInGa metal layer on the Mo layer with DC magnetron sputtering, and then RF magnetron sputtering Depositing a 0.5μm Se layer and finally sputtering a 0.5μm CuInGa layer, and then baking the substrate by an iodine tungsten lamp or other light source. The heating trend is: heating from room temperature for 5 minutes to 350°C and holding at this temperature for 3 to 5 minutes, Then the temperature was raised to 500°C and kept at a constant temperature for 20 minutes to form a light absorption layer, and then the film was stepped down to 350°C within 20 minutes and then naturally cooled to room temperature. The constant temperature process is carried out in a selenium atmosphere.

[0052] The crystal structure of the thin film was tested by XRD and the results are as follows Figur...

Embodiment 2

[0054] The method of preparing a copper indium gallium sulfur solar cell in this example: sputtering and depositing a 1.0 μm Mo back electrode layer on the soda lime glass, and then depositing a CuInGa metal layer 0.4 μm on the Mo layer by DC magnetron sputtering, and then RF magnetron sputtering Depositing the 0.8μm S layer and finally sputtering the 0.6μm CuInGa layer, and then baking the substrate by an iodine tungsten lamp or other light source. The heating trend is: heating from room temperature for 5 minutes to 350°C and holding it at this temperature for 3 to 5 minutes. Then the temperature was raised rapidly to 550°C and kept at a constant temperature for 20 minutes to form a CIGS absorption layer, and then the film was stepped down to 350°C in 20 minutes and then naturally cooled to room temperature. The 550°C constant temperature process is all completed in a sulfur atmosphere.

[0055] The crystal structure of the thin film was tested by XRD and the results are as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com