Rear through-hole interconnected wafer level MOSFET (metal oxide semiconductor field effect transistor) packaging structure and implementation method

A technology of packaging structure and implementation method, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve the problems of restricting the performance improvement of MSOFET, the inability to conduct or dissipate the heat of the chip, and not conforming to semiconductors, etc., to shorten the interconnection distance, Improve the current carrying capacity and enhance the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

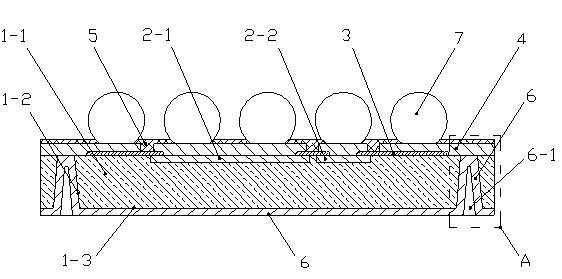

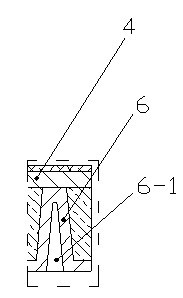

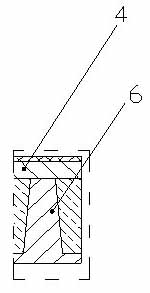

[0024] see figure 1 , figure 1 It is a cross-section schematic diagram of the through-hole interconnection type wafer-level MOSFET packaging structure of the present invention. Depend on figure 1 It can be seen that the packaging structure of the wafer-level MOSFET with post-via interconnection in the present invention includes a chip body 1-1, a chip through hole 1-2, a chip source electrode 2-1, a chip gate electrode 2-2, and a chip surface protection layer. 3. Front circuit layer 4 , circuit surface protection layer 5 , solder balls 7 and circuit layer 6 . The chip source electrode 2-1 and the chip gate electrode 2-2 are arranged on the front of the chip body 1-1, and the chip surface protective layer 3 is arranged on the front of the chip body 1-1, the chip source electrode 2-1 and the chip gate electrode 2-2; The front circuit layer 4 is arranged on the surface of the chip body 1-1, the chip source electrode 2-1, the chip gate electrode 2-2 and the chip surface protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com