Method for treating fly ash by water washing

A fly ash and filtered technology, which is applied in cement production and other directions, can solve problems such as high chlorine content in cement, inability to use reinforced concrete, corrosion, etc., and achieve the effect of harmless disposal and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

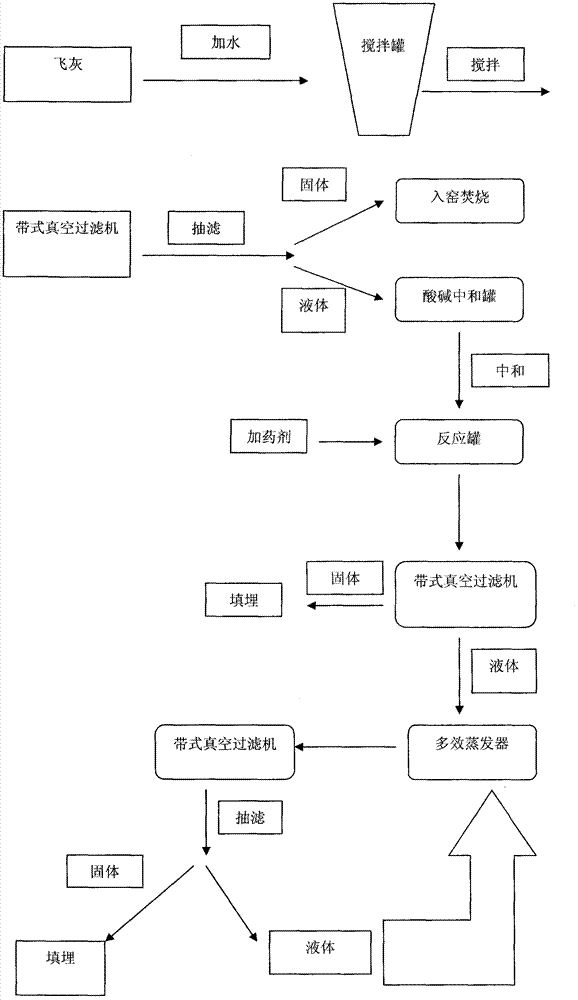

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

[0035] A method for disposing of fly ash by water washing described in this embodiment, the process flow is as shown in the accompanying drawings, including the following steps:

[0036] 1. Washing stage

[0037] (1) Add the fly ash in the warehouse into the mixing tank through the feeding scale, and at the same time, add water and fly ash into the mixing tank according to the ratio of 1:2 to 6 to fully stir and mix; in this embodiment, water and fly ash The ash is added into the mixing tank according to the ratio of 1:4 and fully stirred and mixed.

[0038] (2) Filter the mixture of fly ash and water that has been stirred and mixed through a belt vacuum filter to separate the solid from the liquid;

[0039] (3) The filtered fly ash solid can be put into the cement rotary kiln for incineration through the pre-treatment system, and the filtered liquid enters the acid-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com