Method for producing gamma-chloropropyl trichlorosilane

A technology of chloropropyltrichlorosilane and its production method, which is applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, metal/metal oxide/metal hydroxide catalysts, etc., and can solve problems affecting products Economic benefits, long reaction initiation period, large amount of catalyst, etc., to achieve the effect of reducing the number of auxiliary raw materials, reducing the cleaning workload, and reducing reaction by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

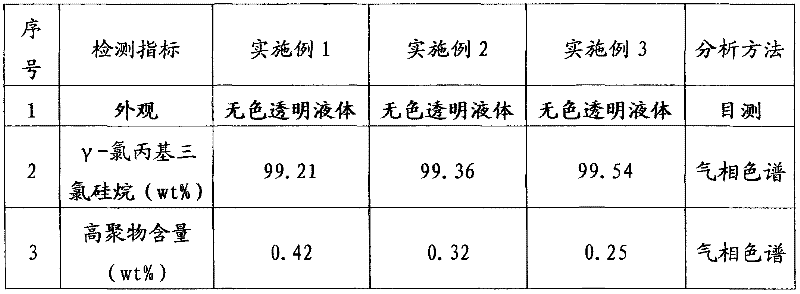

Examples

Embodiment 1

[0036] Add 15 grams of Karstedt platinum catalyst to 500 grams of anhydrous isopropanol, stir and dissolve in an iron-free container for 10 minutes to prepare a platinum catalyst solution, and keep it sealed.

[0037] Add 10 grams of chloroplatinic acid into 350 grams of anhydrous isopropanol, stir and dissolve in an iron-free container for 10 minutes to prepare a chloroplatinic acid catalyst solution, and keep it sealed.

[0038]Under the protection of nitrogen, 360 kg of chloropropene was dried in a desiccator, and 600 kg of trichlorosilane was fully mixed with a pipeline static mixer to form a mixed solution, and the mixed solution was pressed into the head tank, and the initial reaction temperature was controlled at 30 ° C. Add 80 kg of mixed solution in the synthesis kettle, then add 40 grams of platinum catalyst solution, when the reaction temperature reaches 55°C, start to add the remaining mixed solution in the head tank evenly from the bottom of the synthesis kettle, a...

Embodiment 2

[0041] Add 20 grams of Karstedt platinum catalyst into 500 grams of anhydrous isopropanol, stir and dissolve in an iron-free container for 15 minutes to prepare a platinum catalyst solution, and keep it sealed.

[0042] Add 15 grams of chloroplatinic acid into 450 grams of anhydrous isopropanol, stir and dissolve in an iron-free container for 15 minutes to prepare a chloroplatinic acid catalyst solution, and keep it sealed.

[0043] Under the protection of nitrogen, 370 kg of chloropropene was dried in a desiccator, and 620 kg of trichlorosilane was fully mixed with a pipeline static mixer to form a mixed solution, and the mixed solution was pressed into the head tank, and the initial reaction temperature was controlled at 35 ° C. Add 110 kg of mixed solution in the synthesis kettle, then add 50 grams of platinum catalyst solution, when the reaction temperature reaches 58°C, start to add the remaining mixed solution in the head tank evenly from the bottom of the synthesis kettl...

Embodiment 3

[0046] Add 25 grams of Karstedt platinum catalyst into 550 grams of anhydrous isopropanol, stir and dissolve in an iron-free container for 15 minutes to prepare a platinum catalyst solution, and keep it sealed.

[0047] Add 15 grams of chloroplatinic acid into 450 grams of anhydrous isopropanol, stir and dissolve in an iron-free container for 15 minutes to prepare a chloroplatinic acid catalyst solution, and keep it sealed.

[0048] Under the protection of nitrogen, 390 kg of chloropropene was dried in a desiccator, and 650 kg of trichlorosilane was fully mixed with a pipeline static mixer to form a mixed solution, and the mixed solution was pressed into the head tank, and the initial reaction temperature was controlled at 40 ° C. Add 120 kg of mixed solution into the synthesis kettle, and then add 60 grams of platinum catalyst solution. When the reaction temperature reaches 60°C, start to add the remaining mixed solution in the head tank from the bottom of the synthesis kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com