EVA material for sneaker sole and preparation method thereof

A technology for shoe soles and sports shoes, applied in the field of sports shoes, can solve the problems of environmental pollution, difficulty in decomposition, and difficulty in degradation, and achieve the effects of dense and uniform cells, improved printing efficiency, and improved degradable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

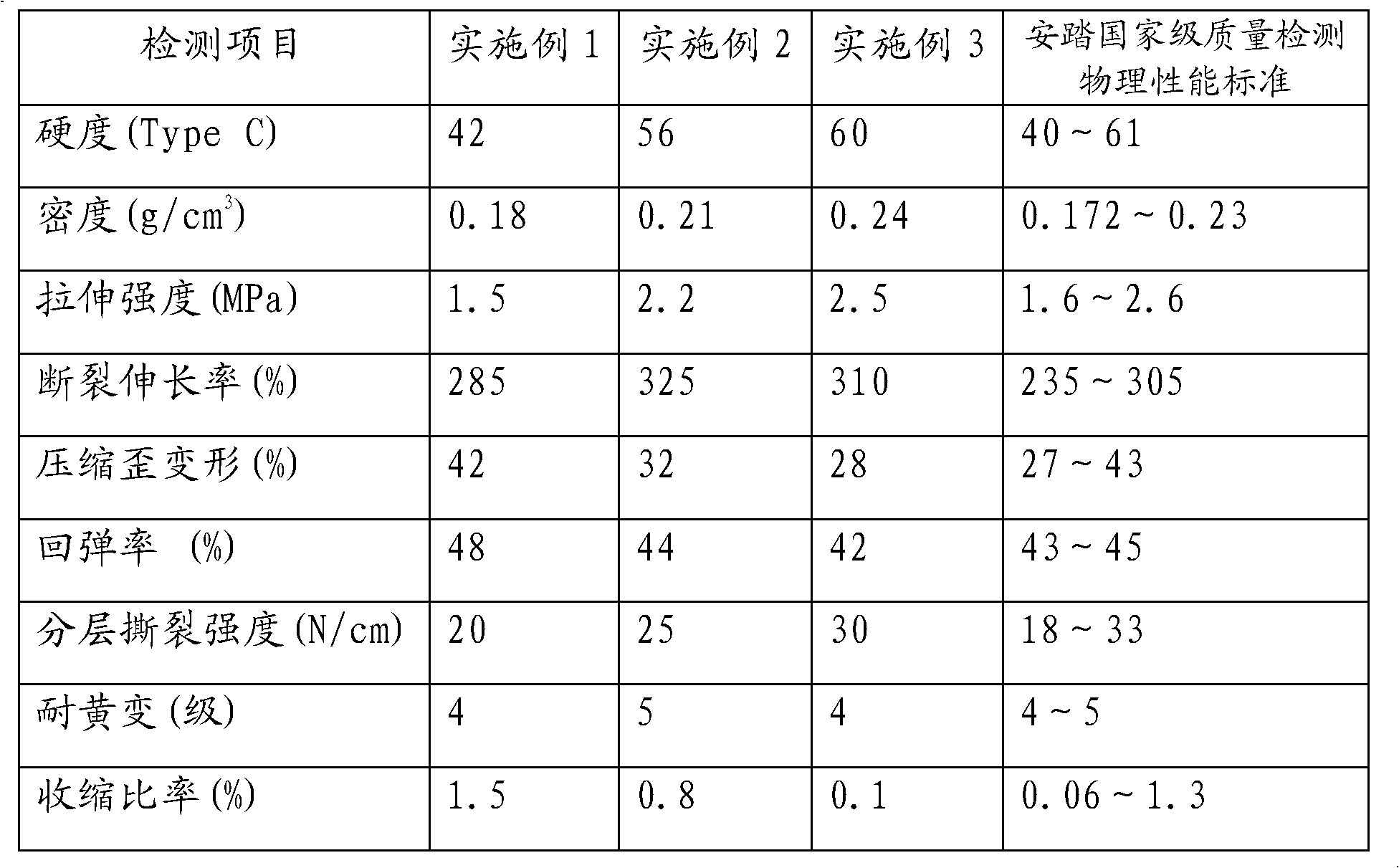

Examples

Embodiment 1

[0040] A kind of EVA material that sports shoe bottom is used, is the EVA foaming material of starch / ethylene-vinyl acetate copolymer / ethylene-alpha-olefin copolymer blending modification, and its production preparation method comprises the following steps:

[0041] ①. Weigh the following components in proportion:

[0042] Ethylene-vinyl acetate copolymer 9000g

[0043] Modified Starch Copolymer 1000g

[0044] Ethylene-a-olefin copolymer 200g

[0048] Stearic acid 200g

[0049] Dicumyl Peroxide 40g

[0050] Azodicarbonamide 500g

[0051] ②. Pour ethylene-vinyl acetate copolymer, modified starch copolymer, ethylene-a-olefin copolymer, filler, zinc oxide powder, zinc stearate, stearic acid and azodicarbonamide into the dense The oil is mixed in the refining machine, the oil mixing time is 7 minutes, and the temperature is 110°C;

[0052] ③. Add dicumyl peroxide to the mixed material in ...

Embodiment 2

[0055]A kind of EVA material that sports shoe sole is used, is the EVA foaming material of starch / ethylene-vinyl acetate copolymer / ethylene-alpha-olefin copolymer blending modification, and its preparation method is: mix ethylene-vinyl acetate in proportion Copolymer 10000g, modified starch copolymer 90000g, ethylene-a-olefin copolymer 5000g, alumina powder 20000g, zinc oxide powder 1000g, zinc stearate 2000g, stearic acid 500g, azodicarbonamide 1200g, pour Mix in the internal mixer, the mixing time is 9 minutes, the temperature is 100°C, after the mixing is uniform, pour 1000g of dicumyl peroxide for mixing, the time is 5 minutes, the temperature is 115°C, and the mixing is uniform Finally, it is poured into the granulator for granulation or wheel table to produce 72960g of green and environmentally friendly EVA foamed material pellets, and then molded and foamed or injected to produce foamed products; after cooling, the semi-finished product is processed and roughened. Secon...

Embodiment 3

[0057] A kind of EVA material that sports shoe sole is used, is the EVA foaming material of starch / ethylene-vinyl acetate copolymer / ethylene-alpha-olefin copolymer blending modification, and its preparation method is: mix ethylene-vinyl acetate in proportion Copolymer 36000g, modified starch copolymer 18000g, ethylene-a-olefin copolymer 6000g, kaolin 9000g, zinc oxide powder 1200g, zinc stearate 600g, stearic acid 800g, azodicarbonamide 1320g, pour into banbury Mixing in the machine, the mixing time is 8 minutes, the temperature is 105°C, after the mixing is uniform, then pour 560g of dicumyl peroxide for mixing, the time is 4 minutes, the temperature is 118°C, after the mixing is uniform, Pour it into the granulator to make granules or roll out the tablets to make 72780g of green and environmentally friendly EVA foamed material pellets, and then foam them by molding or injection molding to produce foamed products; Secondary foam molding (Phylon molding) to obtain the finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com