Preparation method of PbAgTe ternary nanowire

A nanowire and solution technology, which is applied in the field of phase change storage and thermoelectric nanomaterials, can solve the problems of adjusting the uniformity of nanowire size, cumbersome preparation method of nanoparticles, and poor universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

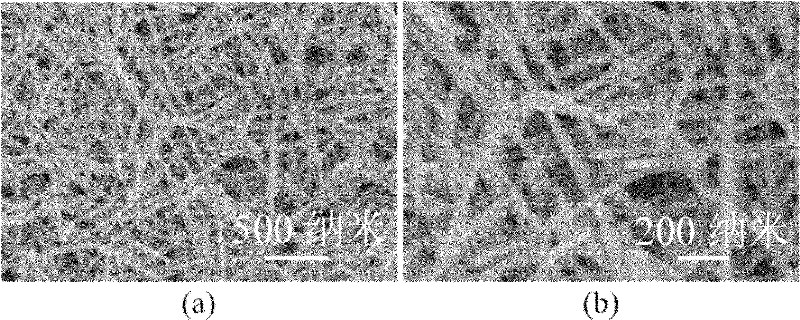

Image

Examples

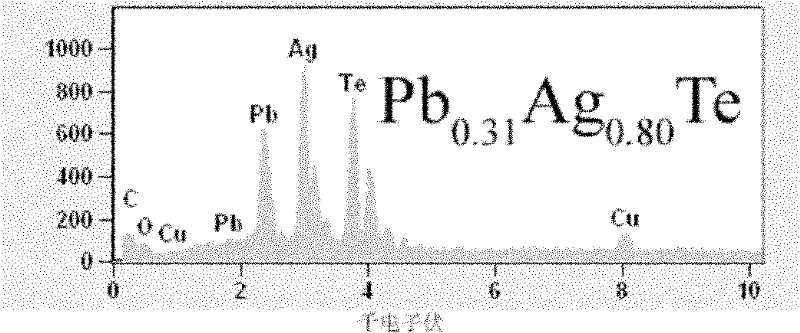

Embodiment 1

[0024] 1. Raw materials: analytically pure H 6 TeO 6 , AgOAc, Pb(OAc) 2 ·3H 2 O.

[0025] 2. Place 0.6 grams of PVP (K30, MW=10000) in a reaction kettle lined with polytetrafluoroethylene with a volume of 25 milliliters, add 7.5 milliliters of double distilled water at room temperature, and magnetically stir to form A homogeneous solution (that is, a PVP solution with a mass fraction of 7.41%).

[0026] 3. Take a 20ml glass bottle and weigh 0.0574g of H 6 TeO 6 (H 6 TeO 6 The mass ratio with PVP is 0.10), add 3 milliliters of twice distilled water, ultrasonic makes it dissolve completely, obtains the H that mass fraction is 1.88% 6 TeO 6 solution. Add it into the autoclave in the second step under magnetic stirring, and continue to stir for 5 minutes to make it fully mixed.

[0027]4. Add 1 ml of 25% ammonia water to the kettle to make the pH of the solution 10, add 0.5 ml of 85% hydrazine hydrate (the solution changes from colorless to brown), and magnetically stir...

Embodiment 2

[0032] 1. Raw materials: analytically pure H 6 TeO 6 , AgOAc, Pb(OAc) 2 ·3H 2 O.

[0033] 2. Place 0.6 g of PVP (K30, MW=10000) in a 50 ml reaction kettle lined with polytetrafluoroethylene, add 15 ml of double distilled water at room temperature, and magnetically stir to form A homogeneous solution (that is, a PVP solution with a mass fraction of 3.85%).

[0034] 3. Take a 20ml glass bottle and weigh 0.1148g of H 6 TeO 6 (H 6 TeO 6 The mass ratio with PVP is 0.19), add 6 milliliters of double distilled water, ultrasonic makes it dissolve completely, obtains the mass fraction that is 1.88% H 6 TeO 6 solution. Add it into the autoclave in the second step under magnetic stirring, and continue to stir for 10 minutes to make it fully mixed.

[0035] 4. Add 2 milliliters of 25% ammonia water to the kettle to make the pH of the solution 10.5, add 1 milliliter of 85% hydrazine hydrate to make the solution change from colorless to brown, and then magnetically stir for 5 min...

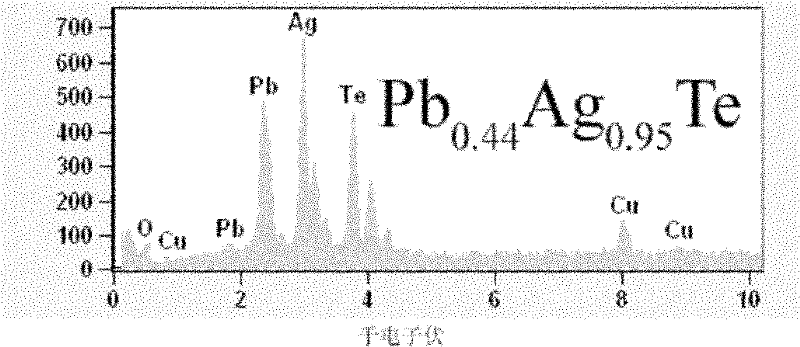

Embodiment 3

[0040] 1. Raw materials: analytically pure H 6 TeO 6 , AgOAc, Pb(OAc) 2 ·3H 2 O.

[0041] 2. Place 0.8 g of PVP (K30, MW=10000) in a 50 ml reaction kettle lined with polytetrafluoroethylene, add 15 ml of double distilled water at room temperature, and magnetically stir to form A homogeneous solution (that is, a PVP solution with a mass fraction of 5.06%).

[0042] 3. Take a 20ml glass bottle and weigh 0.2296g of H 6 TeO 6 (H 6 TeO 6 The mass ratio with PVP is 0.29), add 6 milliliters of double distilled water, ultrasonic makes it dissolve completely, obtains the mass fraction that is 3.69% H 6 TeO 6 solution. Add it into the autoclave in the second step under magnetic stirring, and continue to stir for 10 minutes to make it fully mixed.

[0043] 4. Add 2 milliliters of 25% ammonia water to the kettle to make the pH of the solution 10.5, add 1 milliliter of 85% hydrazine hydrate (the solution changes from colorless to brown), and magnetically stir for 5 minutes, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com