Method for non-invasive efficient purification of single-wall carbon nano tube

A single-walled carbon nanotube, non-destructive technology, applied in nanotechnology and other directions, can solve the problems of excessive sample loss, impurity residue, fragmentation, etc., to achieve the effect of balanced oxidation environment, simple and easy process, and complete oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

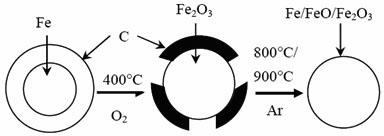

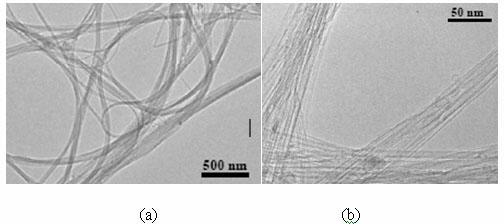

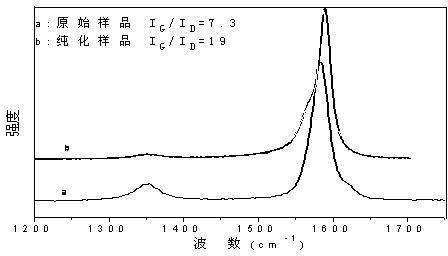

Embodiment 1

[0027] Take a certain amount of original sample of single-walled carbon nanotubes (iron as a catalyst) and spread them in a quartz boat. The diameter of single-walled carbon nanotubes is about 5nm. Put the quartz boat of carbon nanotubes into the quartz tube. The end is open, in order to ensure that the air can enter the quartz tube to fully react, the air bubbler is used to continuously inject air from one end, and let the air flow out from the other end, so as to achieve continuous air supply, balanced oxidation environment, and complete oxidation. Effect. at 10 °C min -1 The furnace temperature was raised to 400°C at a rate of 1 hour. After the air oxidation is over, both ends of the quartz tube are closed and an inert gas argon is introduced as a protective gas. -1 The furnace temperature was raised to 800° C. for 1 h at a high rate. After the high-temperature heat treatment is finished, pass the protective gas argon until the furnace temperature is lowered to room temp...

Embodiment 2

[0029]Take a certain amount of original sample of single-walled carbon nanotubes (iron as a catalyst) and spread them in a quartz boat. The diameter of single-walled carbon nanotubes is about ~1nm. Put the quartz boat into the quartz tube. First, the two ends of the quartz tube are open. , in order to ensure that the air can enter the quartz tube to fully react, an air bubbler is used to continuously inject air from one end, and let the air flow out from the other end, so as to achieve continuous air supply, balanced oxidation environment, and complete oxidation. at 10 °C min -1 The furnace temperature was raised to 400°C at a rate of 1 hour. After the air oxidation is over, both ends of the quartz tube are closed and an inert gas argon is introduced as a protective gas. -1 The furnace temperature was raised to 800° C. for 1 h at a high rate. After the high-temperature heat treatment is finished, pass the protective gas argon until the furnace temperature is lowered to room ...

Embodiment 3

[0031] Take a certain amount of original sample of single-walled carbon nanotubes (iron as a catalyst) and spread them in a quartz boat. The diameter of single-walled carbon nanotubes is about ~1nm. Put the quartz boat into the quartz tube. First, the two ends of the quartz tube are open. , in order to ensure that the air can enter the quartz tube to fully react, an air bubbler is used to continuously inject air from one end, and let the air flow out from the other end, so as to achieve continuous air supply, balanced oxidation environment, and complete oxidation. at 10 °C min -1 Raise the furnace temperature to 500°C at a rate of 1 hour. After the air oxidation is over, both ends of the quartz tube are closed and an inert gas argon is introduced as a protective gas. -1 The furnace temperature was raised to 800° C. for 1 h at a high rate. After the high-temperature heat treatment is finished, pass the protective gas argon until the furnace temperature is lowered to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com