Hydrophobically associating hydroxyethylcellulose oil displacement agent

A technology of synthesizing hydroxyethyl and cellulose, which is applied in drilling compositions, production fluids, wellbore/well components, etc., can solve the problems of difficulty in degradation, high toxicity, large influence of temperature and inorganic salts, etc. Contamination, good viscosity increase and viscoelasticity, effect of improving sweep coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

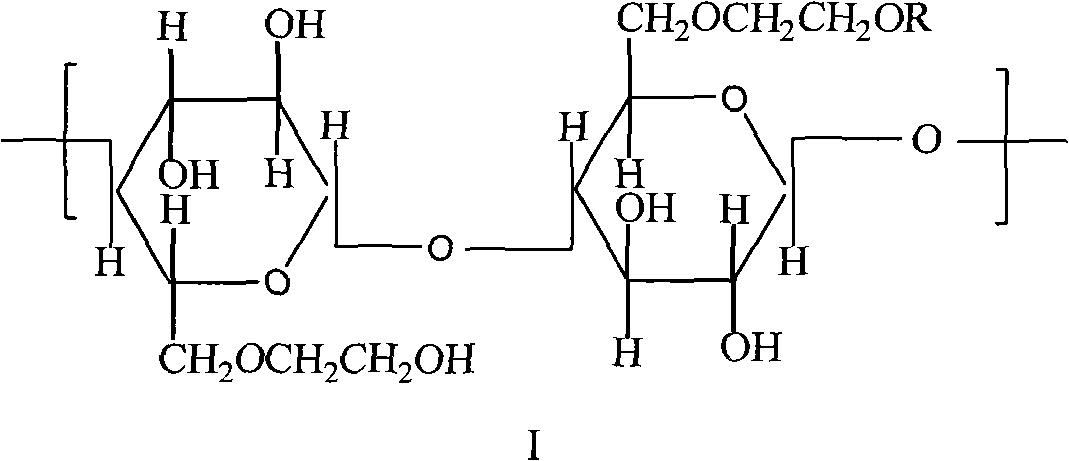

[0039] A hydrophobic association hydroxyethyl cellulose oil displacing agent, the hydrophobic association hydroxyethyl cellulose is C12-hydrophobic association hydroxyethyl cellulose, R is -C in formula I 12 h 25 structural unit. The molecular weight of the hydrophobically associated hydroxyethyl cellulose is 1 million to 1.5 million.

[0040] Synthesis of Hydrophobically Associated Hydroxyethyl Cellulose: Put 6.6g of HEC into a three-neck flask, add 38mL of isopropanol (IPA), stir at room temperature, pass nitrogen gas for 0.5h, and slowly add 35mL of NaOH aqueous solution with a concentration of 3.0wt%. After swelling at room temperature for 24 hours, the temperature was raised to 80°C, and bromododecane-isopropanol solution (bromododecane 2.4mL dissolved in 5mL isopropanol) was slowly added dropwise, and nitrogen gas was introduced again for 0.5h. React at the temperature of 80°C for 6h; decant the product, filter the resulting product, wash the solid once with n-hexane, ...

Embodiment 2

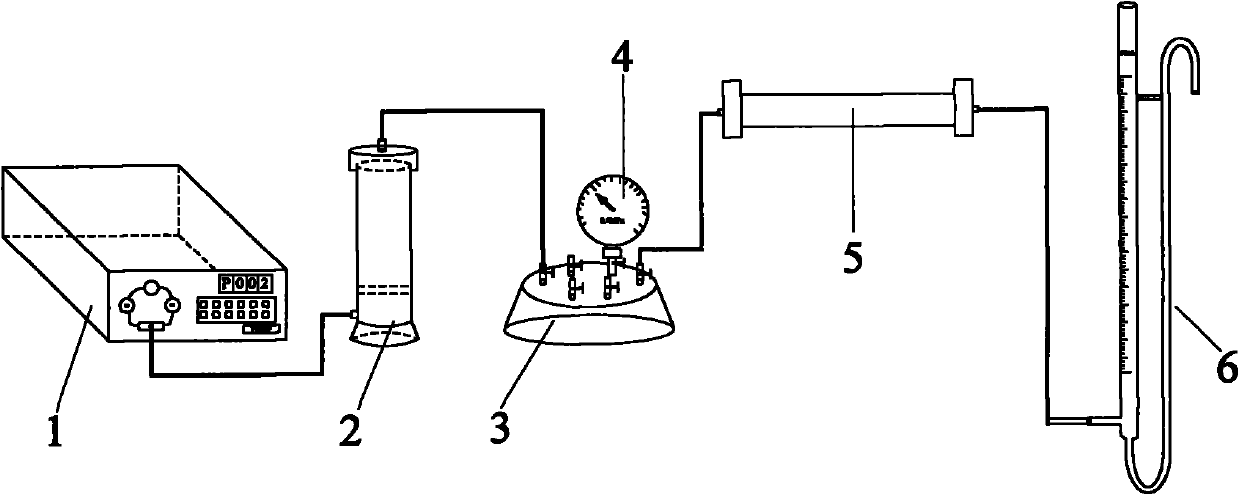

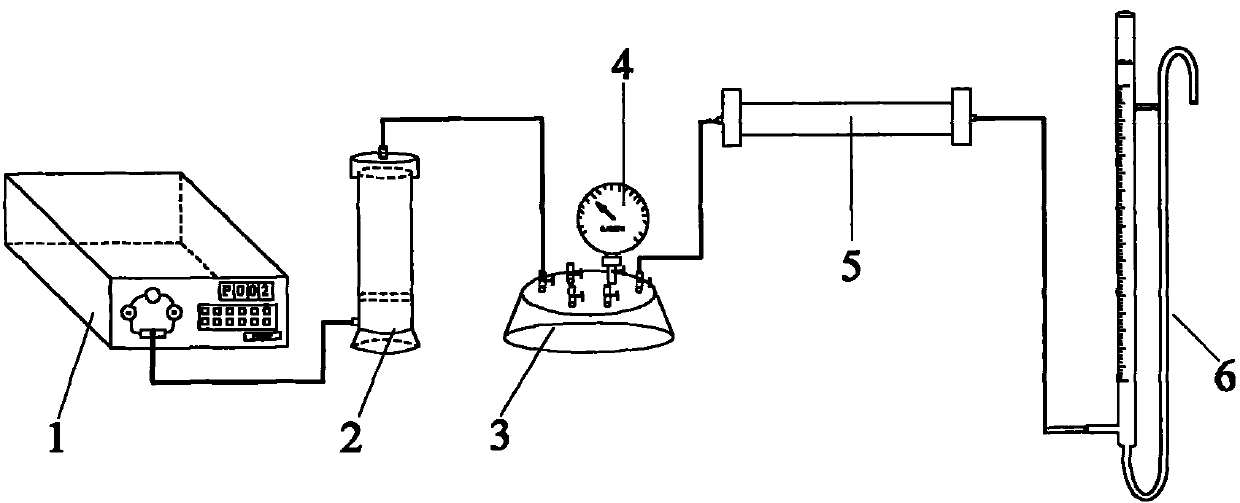

[0043] Embodiment 2: application experiment

[0044] Experimental conditions: homogeneous core, length: 30cm, cross-sectional area: 4.676cm 2 , the core permeability is 1.809μm 2 .

[0045] Crude oil: Liaohe crude oil, the apparent viscosity is 326mPa·s at 25°C.

[0046] Experimental temperature: 25°C.

[0047] Experimental method: Water flooding to a water content of above 98% + 0.5PV of a C12-hydrophobic association hydroxyethyl cellulose aqueous solution with a concentration of 4000mg / L, followed by water flooding to a water content of above 98%.

[0048] Oil flooding results: the water flooding recovery rate is 35.9%, and the enhanced oil recovery rate is 18.4%.

Embodiment 3

[0049] Embodiment 3: As described in Embodiment 2, the difference is:

[0050] The core permeability is 1.822μm 2 , The concentration of C12-hydrophobic association hydroxyethyl cellulose aqueous solution is 5000mg / L.

[0051] Oil flooding results: the water flooding recovery rate is 35.1%, and the enhanced oil recovery rate is 26.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Core permeability | aaaaa | aaaaa |

| Core permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com