Non-halogen flame-retardant thermoplastic elastomer composite with SEBS (Styrene-Ethylene/Butylene-Styrene) as base material and preparation method thereof

A thermoplastic elastomer and composite technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of large amount of flame retardants, potential safety hazards, unsuitable for sustainable development, etc., and achieve good flame retardant performance. and mechanical properties, the effect of easy processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] A preparation method of a halogen-free flame-retardant thermoplastic elastomer compound taking SEBS as a base material, comprising the following steps:

[0015] 1) Put all raw materials in a mixer and mix them evenly;

[0016] 2) Put the mixture into a twin-screw extruder, melt extrude at 175-240°C, draw strands, cool, and pelletize to obtain the final product.

[0017] In step 2), the screw aspect ratio of the twin-screw extruder is 40-60:1.

Embodiment 1

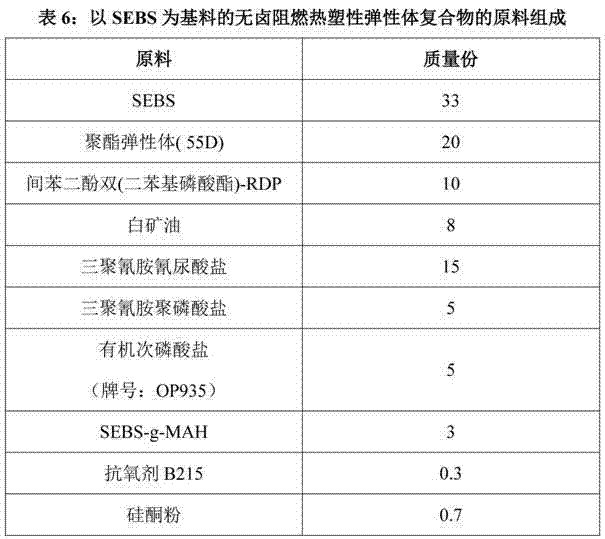

[0020] A halogen-free flame-retardant thermoplastic elastomer compound based on SEBS, its raw material composition is shown in Table 1 below:

[0021]

Embodiment 2

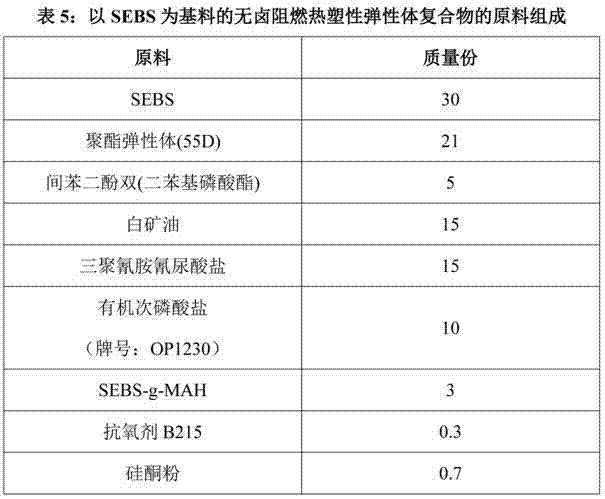

[0023] A halogen-free flame-retardant thermoplastic elastomer compound based on SEBS, its raw material composition is shown in Table 2 below:

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com