Fluorescent material and preparation method thereof

A technology of fluorescent materials and compounds, applied in the field of fluorescent materials for LEDs and their preparation, can solve the problems of poor stability of fluorescent powders, low stability, affecting the life of LED light sources, etc., and achieves high photoexcitation luminous efficiency, Simple preparation method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

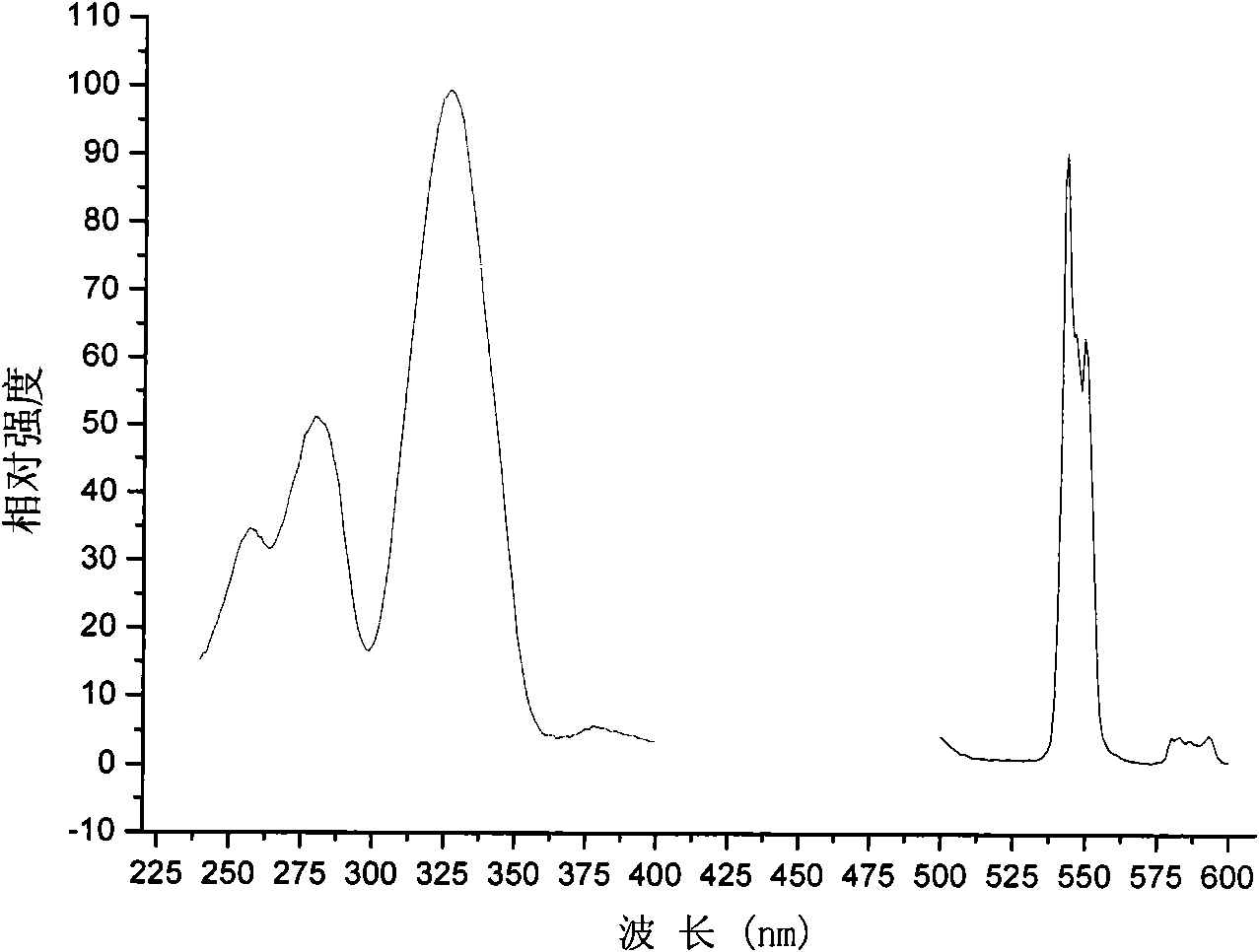

[0029] Weigh 6.886g of cerium oxide, 7.652g of alumina, 1.869g of terbium oxide, and 12.4g of boric acid, mix them in a ball mill, put the above mixture in a corundum crucible, sinter in air at 950°C for 5h, and cool to After room temperature, it is ground in an agate mortar, and finally the ground product is placed in a box-type high-temperature furnace, at a temperature of 840 ° C, under the condition of a mixture of nitrogen and hydrogen (the volume ratio of nitrogen and hydrogen is 95:5) Reduction and sintering for 2h and cooling to obtain Ce 0.8 Al 3 (BO 3 ) 4 : 0.2Tb borate-based green fluorescent material. like figure 1 As shown, the excitation peak position of the fluorescent material is at 320-340 nm, and the emission peak is 544 nm (equipment used in the test: Shimadzu fluorescence spectrometer RF-5301PC, test conditions: low sensitivity, 1.5 nm slit).

Embodiment 2

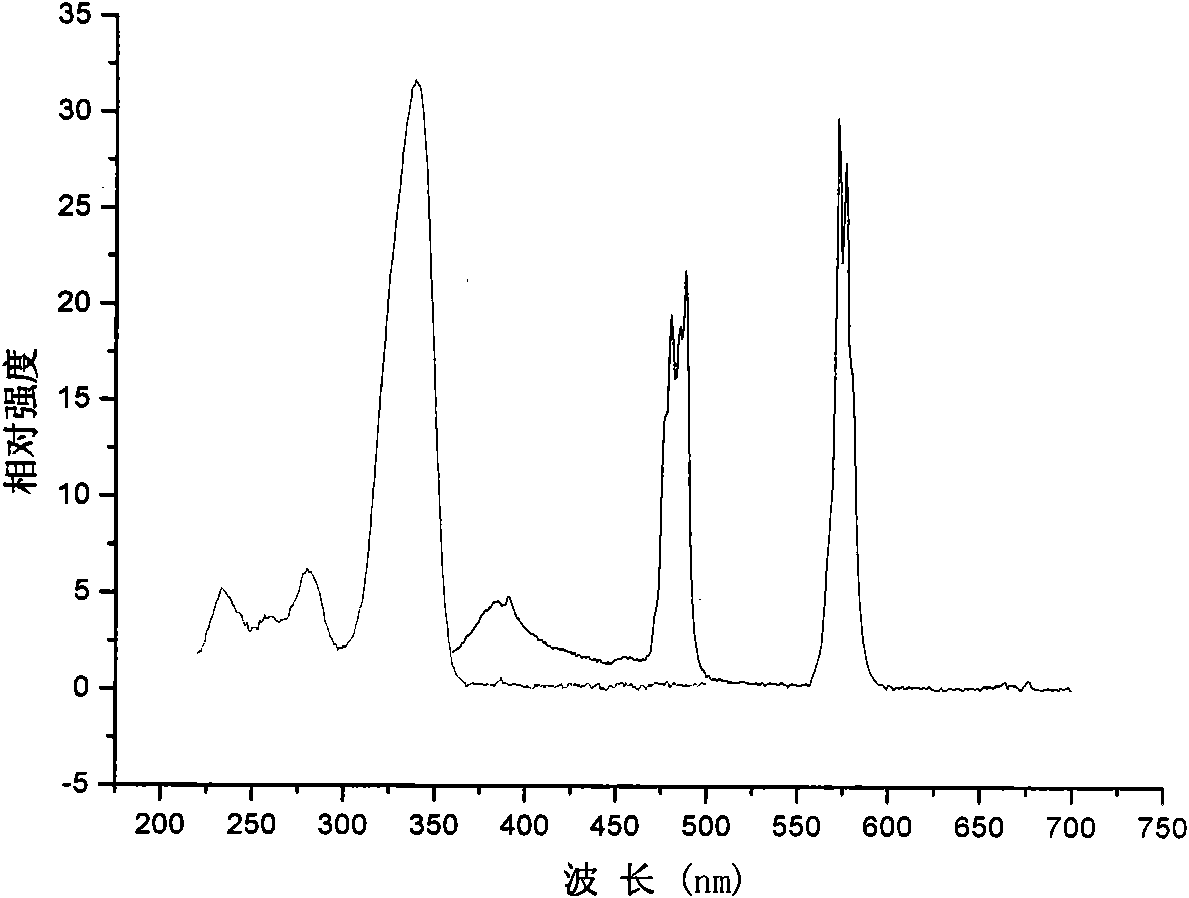

[0031] Weigh 7.74 g of cerium oxide, 7.65 g of alumina, 0.932 g of dysprosium oxide, and 12.4 g of boric acid, mix them in a ball mill, put the above mixture in a corundum crucible, sinter in air at 940°C for 8 hours, and cool to Grind in an agate mortar after room temperature, and finally place the ground product in a box-type high-temperature furnace, at a temperature of 820 ° C, under the condition of a mixture of nitrogen and hydrogen (the volume ratio of nitrogen and hydrogen is 95:5) Reduction and sintering for 4h and cooling to obtain Ce 0.9 Al 3 (BO 3 ) 4 : 0.1Dy borate-based white fluorescent material. like figure 2 As shown, the excitation peak position of the fluorescent material is 320-370 nm, and the emission peaks are 460 nm and 570 nm (equipment used in the test: Shimadzu fluorescence spectrometer RF-5301PC, test conditions: low sensitivity, 1.5 nm slit).

Embodiment 3

[0033] Weigh 17.12 g of cerium oxide, 15.3 g of aluminum oxide, 0.0935 g of terbium oxide, and 24.8 g of boric acid, mix them in a ball mill, put the above mixture in a corundum crucible, sinter in air at 930°C for 5 hours, and cool to Grind in an agate mortar after room temperature, and finally put the ground product in a box-type high-temperature furnace, reduce and sinter for 6 hours at a temperature of 800 °C under the condition of carbon powder to obtain Ce 0.995 Al 3 (BO 3 ) 4 : 0.005Tb borate fluorescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com