Optical vector-matrix multiplier based on single-waveguide coupling micro-ring resonant cavity

A micro-ring resonant cavity and matrix multiplier technology, applied in the field of optical information processing, can solve the problems of low energy utilization rate, difficult system design and installation, etc., to avoid insertion loss, good optical signal parallelism, and good expansion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

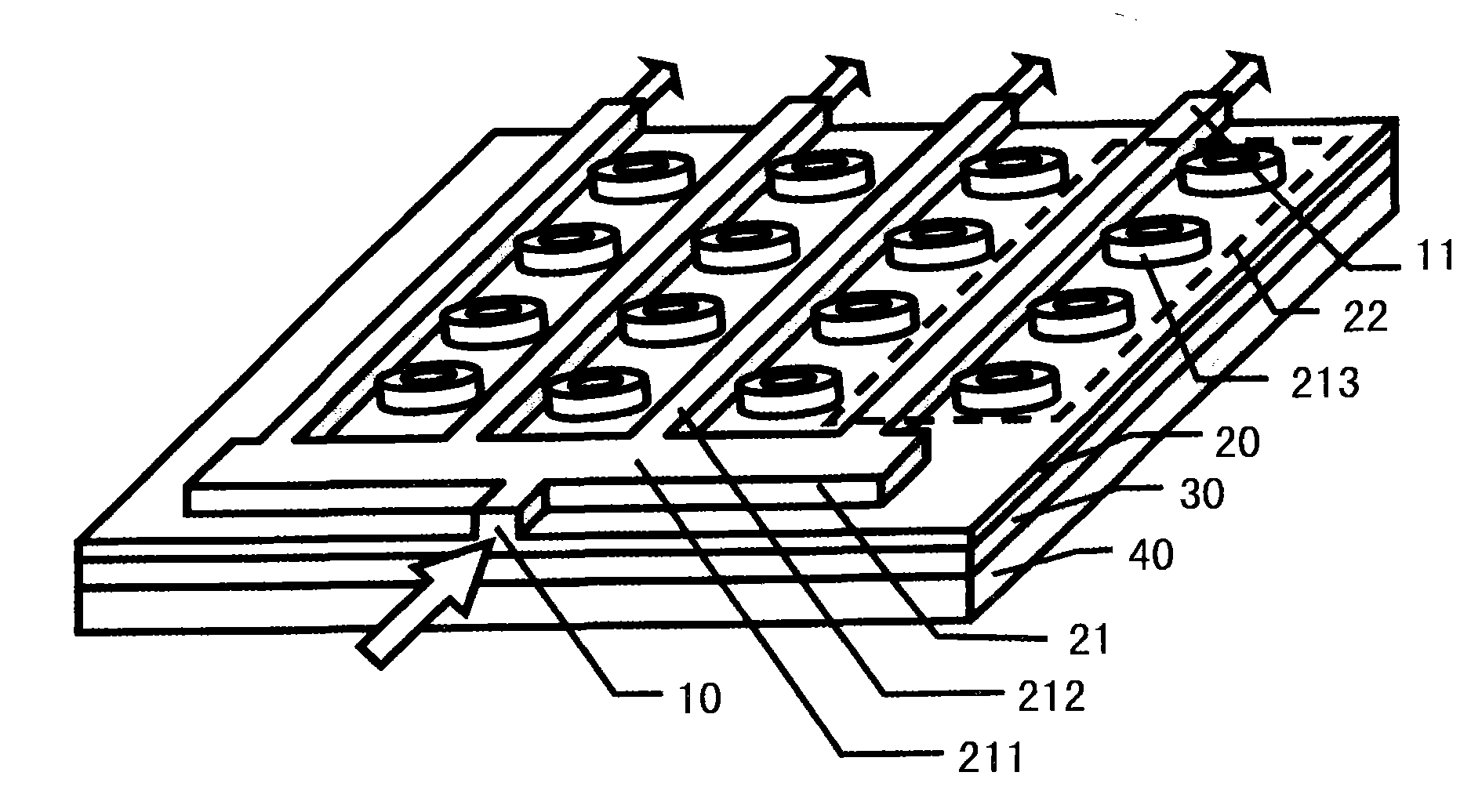

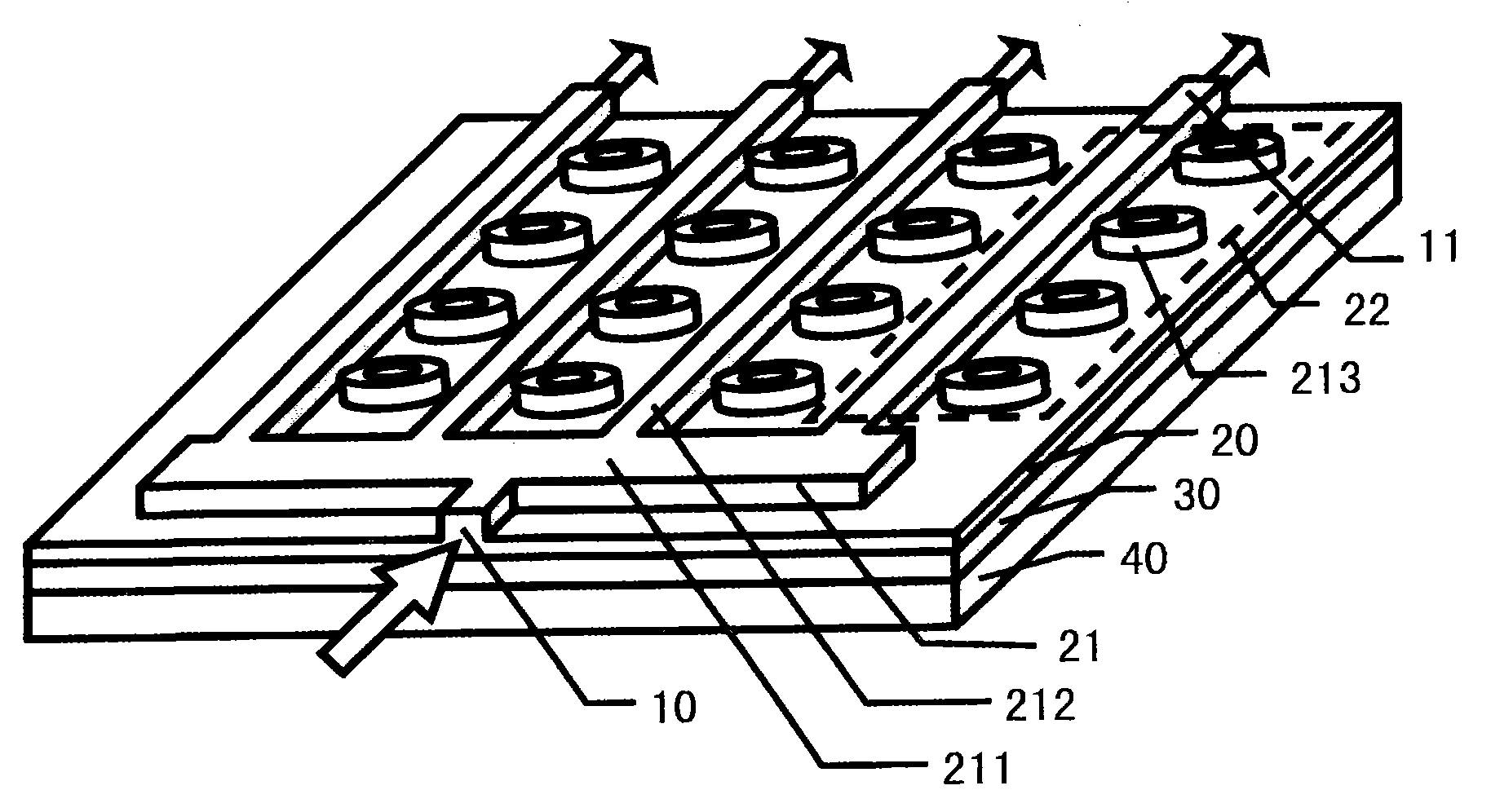

[0026] see figure 1 As shown, the present invention provides an optical vector-matrix multiplier, comprising:

[0027] A substrate 40, the substrate 40 is a silicon substrate;

[0028] A buried layer 30, the buried layer 30 is made on the substrate 40, the material of the buried layer 30 is silicon dioxide, as the cladding of the optical waveguide;

[0029] A top layer 20, the top layer 20 is made on the buried layer 30, the material of the top layer 20 is silicon, a comb structure 21 is etched on the top layer 20, the comb structure 21 includes a back 211 and a tooth portion 212, the comb The shape structure 21 is a beam splitter, and its function is to distribute the input optical signal to the cascaded multi-wavelength modulator 22 corresponding to each tooth of the tooth portion 212 .

[0030] Wherein the middle of the back 211 of the comb structure 21 forms the optical signal input end 10, the optical signal input by the optical signal input end 10 is a multi-wavelength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com