Diffusion method for preparing emitting electrode of polycrystalline silicon solar battery

A technology of solar cells and diffusion methods, applied in the field of polycrystalline silicon solar cells, can solve problems such as limited optimization degree and difficulty in changing doping curves, and achieve the effects of improving cell efficiency, improving minority carrier lifetime, and improving open-circuit voltage and short-circuit current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: A method for preparing a polycrystalline silicon solar cell emitter by double diffusion.

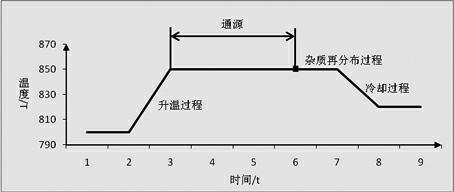

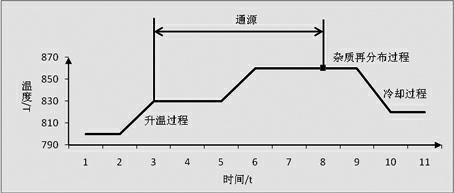

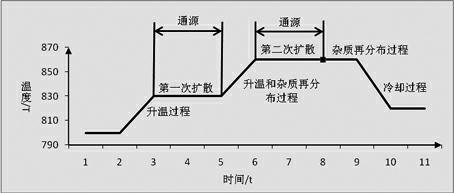

[0035] The polycrystalline 156×156 silicon wafer after cleaning and texturing is diffused using a tubular diffusion furnace. At a temperature of 830°C, a 10-min pre-oxidation is first performed with an oxygen ratio of 10%. Then carry out the first active diffusion for 10min, with a small N ratio of 10%. The temperature is raised to 860 degrees, and the temperature rise rate is 5°C / min. The temperature rise process is also the first redistribution of impurities. The second active diffusion was carried out for 20 min, and the small N ratio was 10%. Finally, the second impurity redistribution process was carried out for 5 minutes, and the oxygen ratio was 10%. Finally, cool down and take out the diffused silicon wafer. Specific process such as image 3 shown. After using the diffusion process twice in this embodiment, and making cells through the subsequent proces...

Embodiment 2

[0036] Embodiment 2: A method for preparing an emitter of a polycrystalline silicon solar cell by three-time diffusion.

[0037]The polycrystalline 156×156 silicon wafer after cleaning and texturing is diffused using a tubular diffusion furnace. At a temperature of 820°C, a pre-oxidation process was first performed for 5 minutes with an oxygen ratio of 10%. Then carry out the first active diffusion for 10min, with a small N ratio of 10%. Raise the temperature to 840°C with a heating rate of 5°C / min. The heating process is also the first redistribution of impurities. The second active diffusion is carried out for 10 min, and the small N ratio is 10%. Then it is raised to 860°C with a heating rate of 5°C / min. The heating process is also the second impurity redistribution. Carry out the third active diffusion for 10 min, and the proportion of small N is 10%. Then carry out the third impurity redistribution process at 860 degrees for 5 minutes, and the oxygen ratio is 10%. Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com