Method for producing steel sectional material of air valve

A production method and technology for steel profiles, which are applied in the field of valve steel profile production, can solve the problems of high hardness and strength of gas valve steel materials, uneven crystal structure, and reduce the comprehensive yield of finished products. The effect of obvious work hardening and high brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

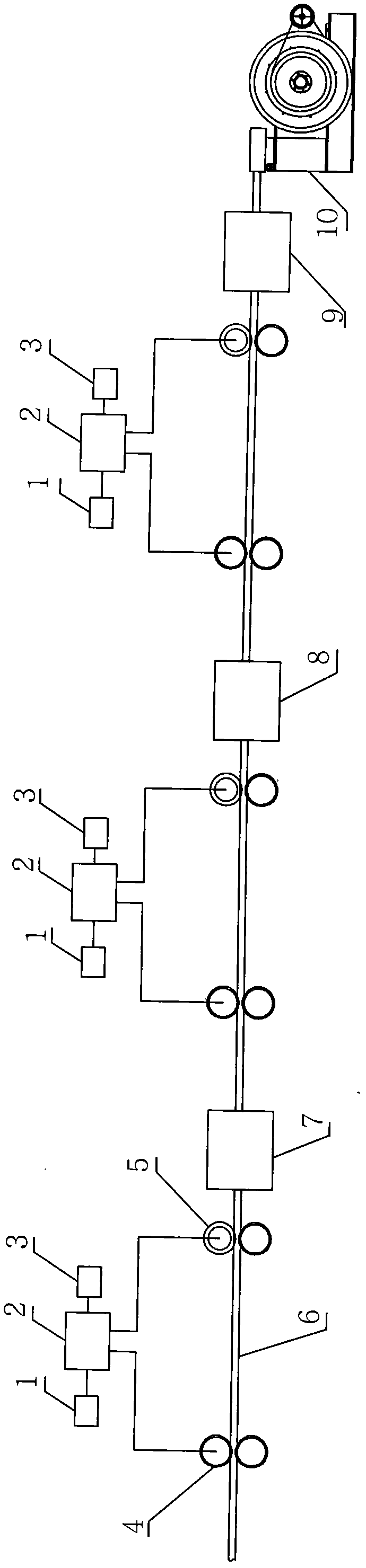

[0025] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0026] The material of this embodiment is: 53Cr21Mn9Ni4N (21-4N), and the warm drawing is carried out three times continuously.

[0027] The furnace number is XJ10-7-46, and the weight is 3216kg.

[0028] The rolling specification of this embodiment: the diameter of the rolled section bar is 8mm, and the finished product specification: the diameter of 5.2mm

[0029] In this embodiment, the temperature drawing adopts the electric contact heating method, and the electric contact heating is as follows: figure 1 As shown, before the inlet end of the drawing die is drawn in each pass, direct current is applied between the negative roller 4 and the positive roller 5, and the temperature of the first drawing pass in this embodiment is controlled within the range of 620°C±15°C, and the pass The area reduction rate is 19.0%; the temperature of the second drawing pass is controlled within the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com