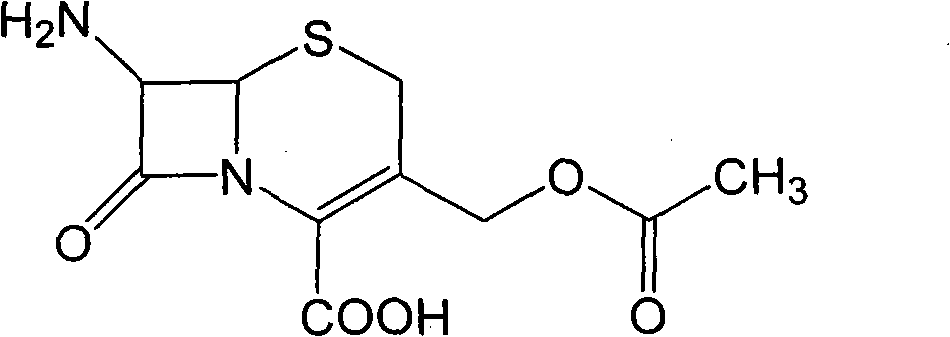

One-step enzymatic method for preparing 7-aminocephalosporanic acid

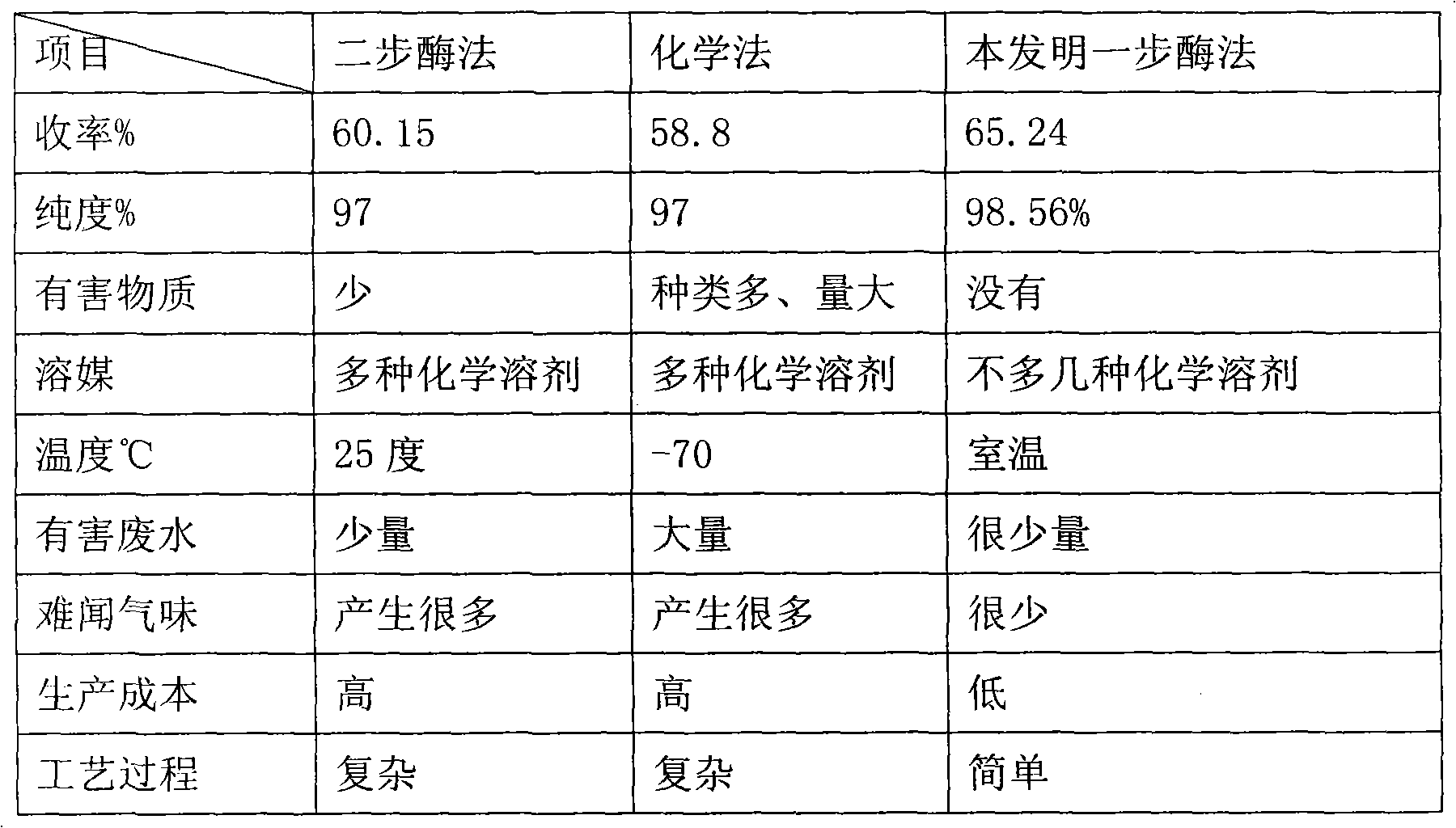

A technology of aminocephalosporanic acid and amino, which is applied in the field of one-step enzymatic method for preparing 7-aminocephalosporanic acid, and can solve the problem of insufficient yield, purity and cost of the two-step enzymatic method, insufficient description of preparation conditions, and product yield. and purity effects, to achieve the effect of mild, safe and fast reaction conditions, fewer steps, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The pretreatment of embodiment 1. cephalosporin C (CPC) liquid:

[0033] Take 1 liter of cephalosporin C (CPC) fermentation filtrate (75mM, equivalent to 31.1 grams of pure CPC), filter through a 1 μm membrane, and adjust the pH to 10 with ammonia water.

Embodiment 2

[0034] Embodiment 2 reaction conditions control:

[0035] Add 167 grams of (NRB-103) enzyme into the reactor, wash twice with water, add CPC solution, under rapid stirring, control the pH to 10 with ammonia water, react for 30 minutes, and the 7-ACA conversion rate is 98%.

Embodiment 3

[0036] The processing of embodiment 3 lysate (7-ACA liquid):

[0037] To the resulting 2 liters of 7-ACA solution was added 10 g of Na 2 S 2 o 4 , adjust the pH to 7 with ammonia water, add Tween 80, 1 ml, add 200 ml of dichloromethane, stir for 10 minutes, separate phases, add 2.0 grams of activated carbon to the water phase, add 1.0 grams of EDTA, stir for 15 minutes, filter Remove carbon to obtain 7-ACA treatment solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com