Fabric coating finishing agent with electromagnetic shielding function and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

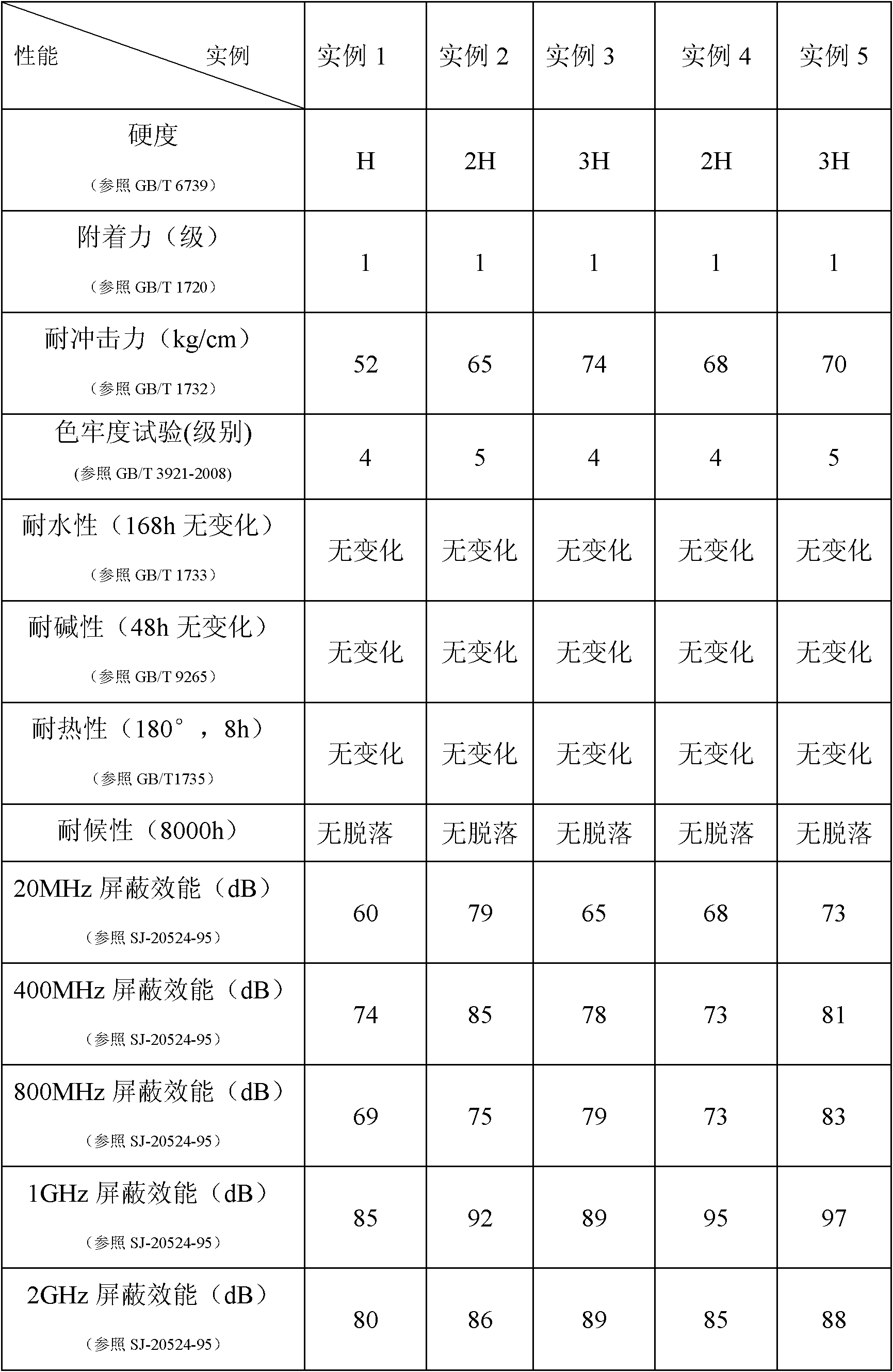

Examples

Embodiment 1

[0032] Step 1: Soak 7g of fabric in 10g of diethanolamine solution, then add 10g of FeCl 3 ·6H 2 O, FeCl 2 4H 2 O (the ratio is 2:1), add 50mL of distilled water, stir for 15min under the protection of nitrogen, add dropwise 10mL of 0.5mol / L NH 4 OH solution, adjust pH=7, ultrasonic dispersion, continue to react for 1h, then magnetically separate, wash with 1g of 1mol / L sodium oleate for several times, then take out the fabric and dry it at 60°C for 2h to obtain product A.

[0033] Step 2: Soak the fabric A loaded with 1g of ferric oxide nanoparticles in 40mL of deionized aqueous solution of pyrrole monomer after drying, and drop 10g of FeCl 3 The solution was continuously stirred for 2 h under the protection of nitrogen, washed several times with water and absolute ethanol, and dried at 40° C. for 12 h for later use to obtain product B.

[0034] Step 3: Take the fabric B loaded with 40.7g of nano-ferric oxide / polypyrrole conductive composite material, mix it with 38.4g of...

Embodiment 2

[0037] Step 1: Soak 15g of fabric in 14.5g of polyethylene glycol solution, then add 18g of FeCl 3 ·6H 2 O, FeCl 2 4H 2 O (ratio 2.2:1), add 60mL of distilled water, stir for 20min under nitrogen protection, add dropwise 15mL of 1mol / L NH 4 OH solution, adjust pH=7.5, ultrasonic dispersion, continue to react for 1.5h, then magnetically separate, wash with 5mL of 1mol / L sodium oleate for several times, then take out the fabric and dry it at 60°C for 2h to obtain product A .

[0038] Step 2: Soak the fabric A loaded with 5g of ferric oxide nanoparticles in 45mL of deionized aqueous solution of pyrrole monomer after drying, and drop 52g of FeCl 3 The solution was continuously stirred for 4 h under the protection of nitrogen, washed several times with water and absolute ethanol, and dried at 40° C. for 12 to obtain product B.

[0039] Step 3: Mix the fabric B loaded with 47.6g of nano-ferric oxide / polypyrrole conductive composite material with 51.2g of water-based polyurethan...

Embodiment 3

[0042] Step 1: Soak 24g of fabric in 22g of Decyltrimethylammonium bromide solution, then add 26.8g of FeCl 3 ·6H 2 O, FeCl 2 4H 2 O (ratio 2.7:1), add 65mL of distilled water, stir for 30min under nitrogen protection, add dropwise 20mL of 2.5mol / L NH 4 OH solution, adjust pH=8, ultrasonic dispersion, continue to react for 2h, then magnetically separate, wash with 10mL of 5mol / L sodium oleate for several times, then take out the fabric and dry it at 60°C for 2h to obtain product A.

[0043] Step 2: Soak the fabric A loaded with 13.6g ferric oxide nanoparticles in the deionized aqueous solution of 54g pyrrole monomer after drying, drop 70g of FeCl 3 The solution was continuously stirred for 4 h under the protection of nitrogen, washed several times with water and absolute ethanol, and dried at 50° C. for 18 h for later use to obtain product B.

[0044] Step 3: Mix the fabric B loaded with 59.2g of nanometer ferric oxide / polypyrrole conductive composite material with 64.6g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com