Silicon wafer etching bath liquid isolation type uniform heating device

A uniform heating and texturing tank technology, which is applied in the direction of heating elements, sustainable manufacturing/processing, ohmic resistance heating parts, etc., can solve the problem of not meeting the production requirements of large-scale texturing process, difficult temperature uniformity requirements, and reducing Problems such as production capacity of texturing equipment, to achieve uniform and more stable temperature environment, uniform heating temperature, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

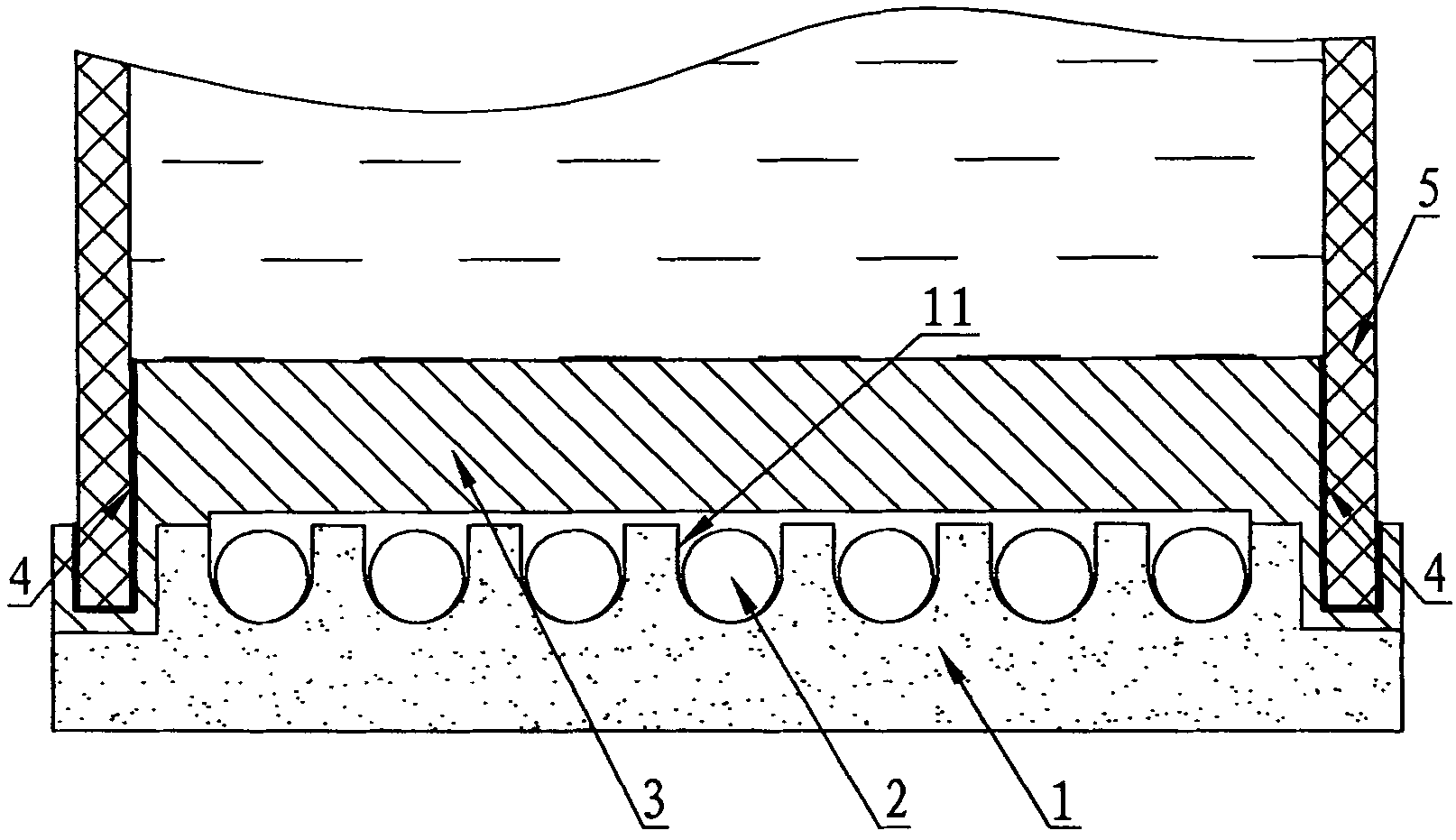

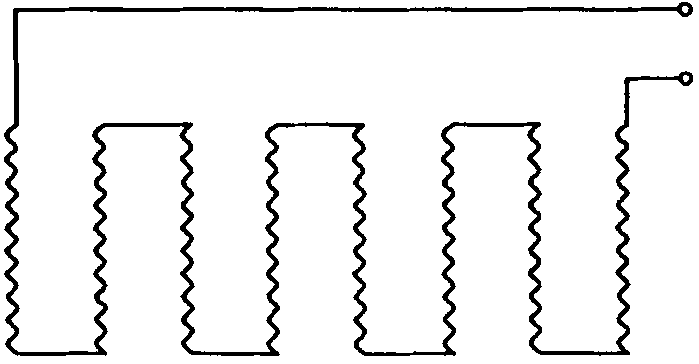

[0014] Example 1: A liquid-isolated uniform heating device for a silicon wafer texturing tank, including a heat-insulating base 1, an electric heating coil 2, a stainless steel plate 3, a corrosion-resistant adhesive layer 4 and a texturing tank body 5. The base 1 is provided with a groove 11 for arranging the electric heating coil 2, the depth of the groove 11 is greater than the diameter of the electric heating coil 2, the electric heating coil 2 is arranged in the groove 11, and the stainless steel plate 3 is arranged above the heat-insulating base 1 The texture tank body 5 is bonded together with the stainless steel plate 3 through the corrosion-resistant adhesive layer 4, and the heat dissipation area of the stainless steel plate 3 is equivalent to the bottom of the cashmere tank. When the electric heating coil 2 is energized and heated, the heat emitted by the electric heating coil first makes the temperature of the entire stainless steel plate 3 rise evenly, and the li...

Embodiment 2

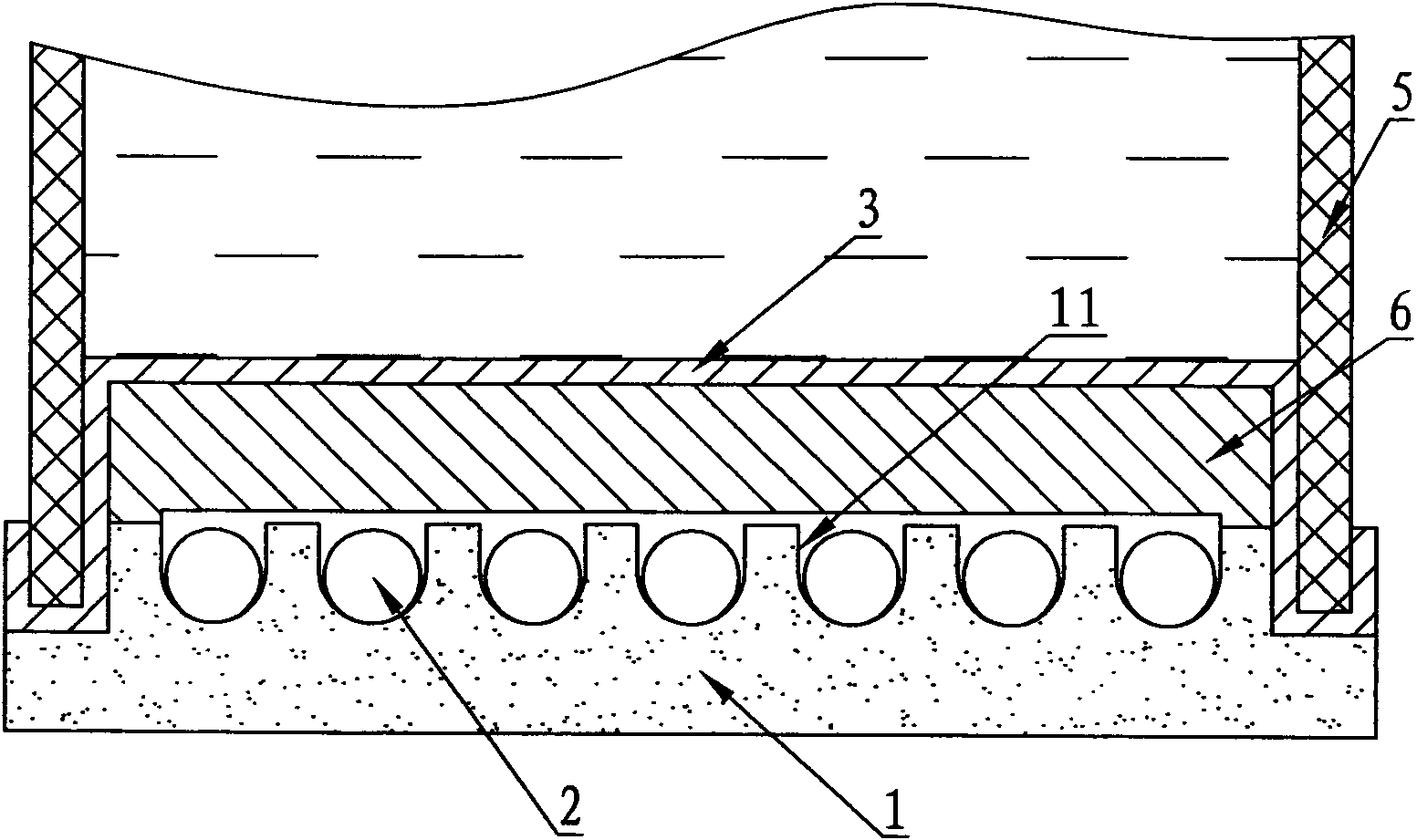

[0015] Embodiment 2: In Embodiment 1, the thickness of the stainless steel plate 3 is 2 mm, a copper block 6 is provided between the stainless steel plate 3 and the heat insulating base 1 , and the upper end surface of the copper block 6 is in close contact with the stainless steel plate 3 . The red copper block 6 has good thermal conductivity. When the electric heating coil 2 is energized and heated, the heat emitted by the electric heating coil 2 is first absorbed by the red copper block 6, and then transmitted to the stainless steel plate 3, so that the temperature rises evenly. The liquid is heated uniformly and synchronously by 3 stainless steel plates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com