Functional health care beverage and preparation method and application thereof

A health beverage and functional technology, applied in the field of health beverages, can solve problems such as single ingredients, unclear preparation methods, and inability to guarantee nutritional and health value auxiliary treatment effects, etc., to achieve good taste, enhance human endurance and immunity, and improve resources The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

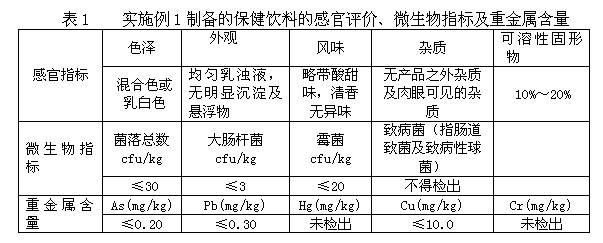

Embodiment 1

[0029] Example 1: According to the composition and weight ratio of raw materials: 30% okra tender fruit, 20% medlar, 15% Chinese yam, 6% honey, and the rest is the proportion of pure water, using the crushing mixing method, the raw materials are put into the tissue and broken In the extractor container, the motor power of the crusher extractor is 840 W. Turn on the switch to crush at a speed of 10000 r / min for 6 minutes. After high-speed crushing, stirring, mixing, emulsification, and homogenization, the raw materials are crushed into a homogenous slurry. Shape, become puree.

Embodiment 2

[0030] Example 2: According to the composition and weight ratio of the raw materials: 40% okra tender fruit, 15% medlar, 10% yam, 8% honey, and the rest is pure water, using the crushing mixing method, the raw materials are put into the tissue and broken In the extractor container, the motor power of the crusher extractor is 840 W. Turn on the switch and crush for 7 minutes at a speed of 10,000 r / min. After high-speed crushing, stirring, mixing, emulsification, and homogenization, the raw materials are crushed into a homogenous slurry. Shape, become puree.

Embodiment 3

[0031] Example 3: According to the composition and weight ratio of the raw materials: 40% okra tender fruit, 5% wolfberry, 15% yam, 10% honey, and the rest is the proportion of pure water, using the crushing mixing method, the raw materials are put into the tissue and broken In the extractor container, the motor power of the crushing extractor is 840 W, and the switch is turned on at a speed of 10000 r / min for 6 minutes. After high-speed crushing, stirring, mixing, emulsification, and homogenization, the raw materials are crushed into a homogeneous slurry. , Become the puree.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com