Hybrid welding method of variable-polarity square-wave tungsten electrode argon arc and laser

A tungsten argon arc and hybrid welding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high welding cost, slump, poor stability, etc., and achieve the goal of reducing reflectivity and improving absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

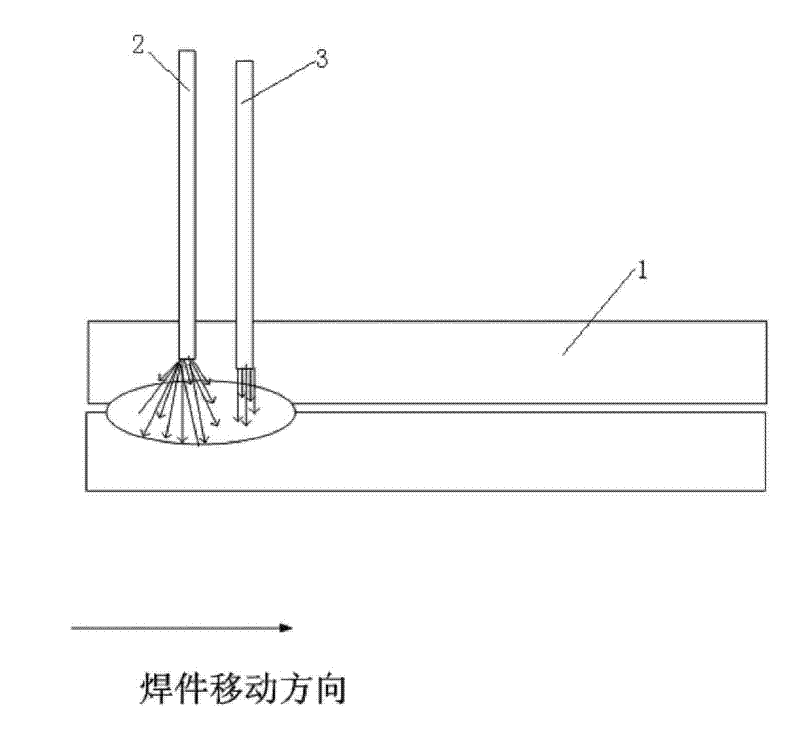

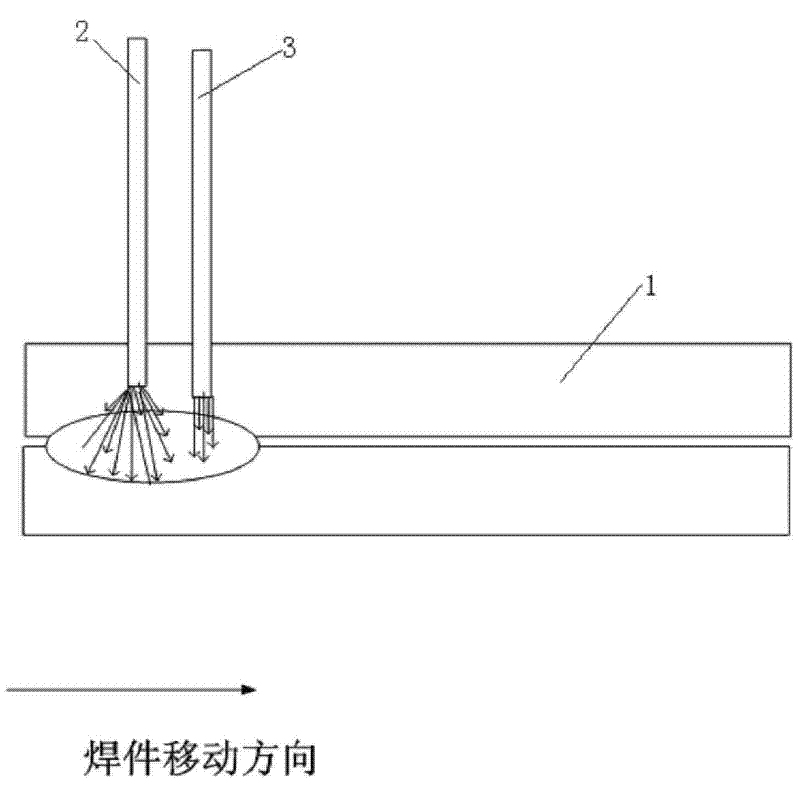

[0029] As shown in Figure 2, the composite welding method of the present invention adopts the polarity-variable square-wave argon tungsten arc and the laser composite heat source to carry out butt welding of metal plates or profiles such as aluminum alloys, and the metal plates or profiles can be aluminum alloys, One or two materials in magnesium alloy, copper alloy, titanium alloy and low-alloy steel. This embodiment takes the butt welding of two aluminum alloy plates as an example to describe in detail, wherein the thickness of the aluminum alloy plate is 8mm. The width is 200mm and the length is 1000mm.

[0030] The variable polarity square wave tungsten electrode is Φ2.4mm WC20, the distance between the top of the electrode and the workpiece surface is 3mm, the diameter of the nozzle is 6.0mm, and the stem extension of the tungsten electrode i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com