Method for synthesizing sucrose-6-palmitate by using lipase through catalytic selectivity

A technology of palmitate and vinyl palmitate, used in chemical instruments and methods, esterified saccharides, sugar derivatives, etc., can solve the problems of long reaction time and low yield of monoester, and achieve high conversion and Effects of selectivity, shortened reaction time, high monoesterification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

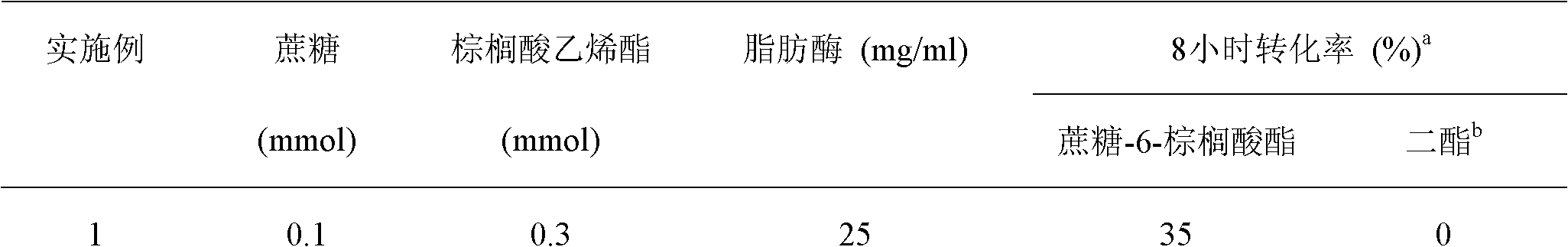

Embodiment 1-5

[0024] Synthesis of sucrose-6-palmitate: Add sucrose (0.1 mmol, 0.0342 g) and lipase Lipozyme RM IM (25 mg / ml) to 4 mL tert-amyl alcohol in a 25 mL stoppered Erlenmeyer flask: DMSO=4: 1(v / v) of the mixed solvents, the mixed solvents are used first Molecular sieve treatment for 24h, 170r-min at 40°C -1 The rotation speed is mixed in the shaker for 30 minutes first, then vinyl palmitate is added, and then put into the shaker for reaction, and the reaction result is tracked and detected by thin-layer chromatography (TLC).

[0025] After the reaction was finished, the lipase was removed by filtration, the solvent was distilled off under reduced pressure, and the column was wet-packed with 200-300 mesh silica gel. The eluent was chloroform:methanol=10:1, the column height was 35cm, and the column diameter was 4.5cm. The sample was washed with a small amount of After the deagent is dissolved, apply the wet method to the column, and the eluent is collected at a flow rate of 2mL min...

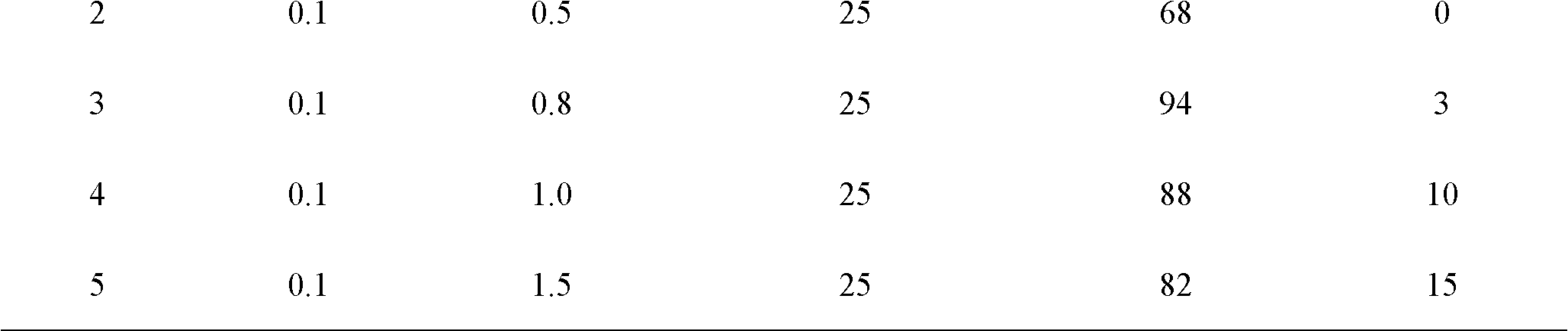

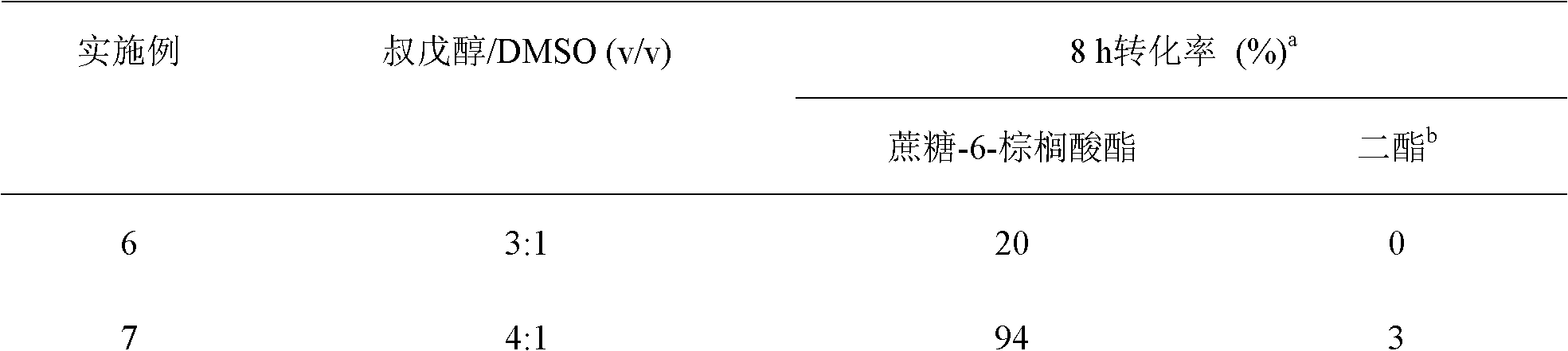

Embodiment 6-14

[0035] Synthesis of sucrose-6-palmitate: Add sucrose (0.1mmol, 0.0342g) and lipase Lipozyme RM IM (25mg / ml) to a mixed solvent of 4mL tert-amyl alcohol and DMSO in a 25mL stoppered Erlenmeyer flask In, mixed solvents are used first Molecular sieve treatment for 24h, 170r-min at 40°C -1 The rotation speed was mixed in the shaker for 30 minutes first, then vinyl palmitate (0.8 mmol) was added, and then placed in the shaker for reaction, and the reaction result was tracked and detected by thin-layer chromatography (TLC).

[0036] After the reaction was finished, the lipase was removed by filtration, the solvent was distilled off under reduced pressure, and the column was wet-packed with 200-300 mesh silica gel. The eluent was chloroform:methanol=10:1, the column height was 35cm, and the column diameter was 4.5cm. The sample was washed with a small amount of After the deagent is dissolved, apply the wet method to the column, and the eluent is collected at a flow rate of 2mL min ...

Embodiment 15-20

[0044] Synthesis of sucrose-6-palmitate: sucrose (0.1mmol, 0.0342g) and lipase Lipozyme RM IM were added to 4mL tert-amyl alcohol in a 25mL stoppered Erlenmeyer flask: DMSO=4:1 (v / In the mixed solvents of v), the mixed solvents are first used Molecular sieve treatment for 24h, 170r-min at 40°C -1 The rotation speed was mixed in the shaker for 30min first, then vinyl palmitate (0.8mmol) was added respectively, and then put into the shaker for reaction, and the reaction result was tracked and detected by thin-layer chromatography (TLC).

[0045] After the reaction was finished, the lipase was removed by filtration, the solvent was distilled off under reduced pressure, and the column was wet-packed with 200-300 mesh silica gel. The eluent was chloroform:methanol=10:1, the column height was 35cm, and the column diameter was 4.5cm. The sample was washed with a small amount of After the deagent is dissolved, apply the wet method to the column, and the eluent is collected at a flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com