Preparation method of colistin methane sodium sulfonate

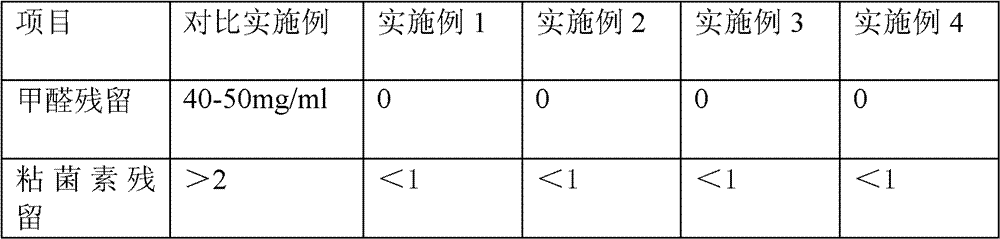

A technology of sodium methanesulfonate and sodium hydroxymethanesulfonate is applied in the field of preparation of pharmaceutical and chemical raw materials, and can solve the problems of residue, increased toxicity, unstable product quality, etc., and achieves easy control, content reduction, and avoidance of formaldehyde residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 40kg of colistin sulfate, dissolve it in 400L deionized water, stir and add 25% ammonia water to adjust the pH of the solution to 10.0, maintain the reaction for 1 hour, filter with suction, and then wash the filter cake with deionized water until the pH of the effluent is 8.90. Add the above filter cake to 150L deionized water, stir evenly, and prepare colistin suspension;

[0021] Take 28kg of sodium hydroxymethanesulfonate, dissolve it in 220L of deionized water, add the sodium hydroxymethanesulfonate solution to the colistin suspension prepared in advance, heat to 65°C, and maintain it for 1 hour until the solution is clear and transparent. Rapidly cool down to below 20°C. Add the above reaction solution to the regenerated mixed resin composed of 24kg of 001×16 styrene-based strong acidic cation exchange resin and 50kg of 703 model acrylic weakly basic anion-exchange resin, maintain the reaction for 0.5 hours, and filter to obtain a clear and transparent solut...

Embodiment 2

[0023] Weigh 100kg of colistin sulfate, dissolve it in 1000L deionized water, stir and add 25% ammonia water to adjust the pH of the solution to 11, filter with suction, and then wash the filter cake with deionized water until the pH of the effluent is 8.0. Add the above filter cake to 500L deionized water, stir evenly, and prepare colistin suspension;

[0024] Take 56kg of sodium hydroxymethanesulfonate, dissolve it in 560L of deionized water, add the sodium hydroxymethanesulfonate solution to the previously prepared colistin suspension, heat the reaction solution to 55°C, and maintain it for 3 hours until the solution is clear Transparent, quickly cool down to normal temperature. Add the above solution to the regenerated mixed resin composed of 60kg of styrene-based strongly acidic cation exchange resin of model 001x16 and 120kg of weakly basic anion-exchange resin of model 703 acrylic system, keep the reaction for 1 hour, and filter the solution to obtain a clear and transp...

Embodiment 3

[0026] Take by weighing colistin sulfate 150kg, be dissolved in 1500L deionized water, stir and add 20% sodium hydroxide to adjust the pH of the solution to 12.0, maintain the reaction for 2 hours, filter with suction, then clean the filter cake with deionized water to effluent pH9. 0 ends. Add the above filter cake to 750L deionized water, stir evenly, and prepare colistin suspension;

[0027] Take 74.5kg of sodium hydroxymethanesulfonate, dissolve it in 190L deionized water, add the sodium hydroxymethanesulfonate solution to the colistin suspension prepared in advance, heat the reaction solution to 80°C, and maintain it for 2 hours until The solution is clear and transparent; add the above solution at 40°C, concentrate by rotary evaporation 4 times, cool down to below 25°C, add the above solution into the regenerated 94kg of styrene-based strong acid cation exchange resin of model 001x7, and acrylic acid of model D318 A mixed resin composed of 263 kg of weakly basic anion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com