Spaceborne calibration light source LED (light emitting diode) light emitting performance testing device

A technology of luminous performance and on-board calibration, applied in the field of space optics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

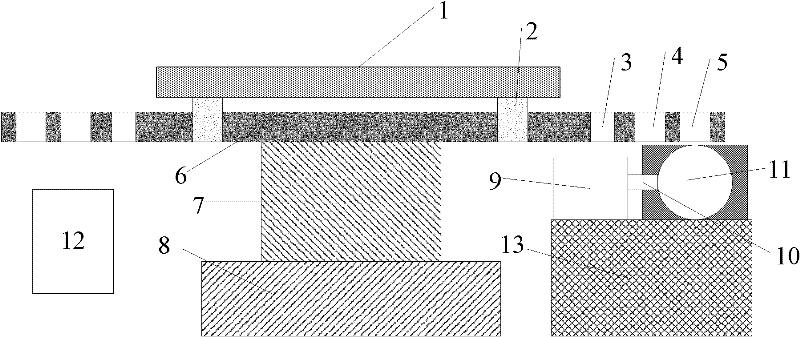

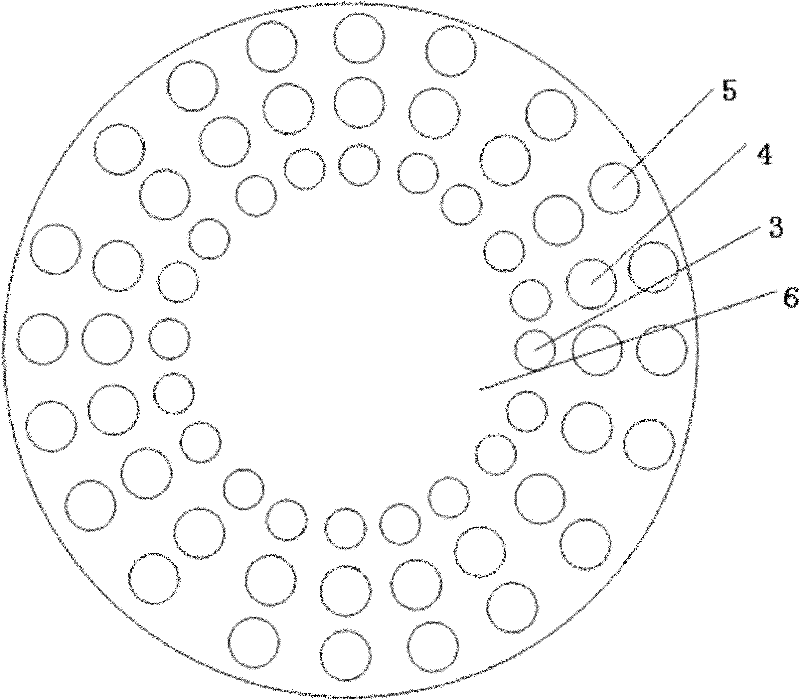

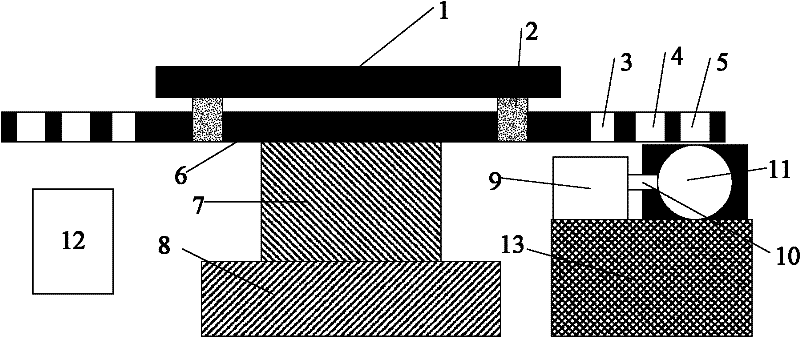

[0010] Specific implementation mode 1. Combination figure 1 and figure 2 Describe this embodiment, the on-board calibration light source LED luminous performance test device, the device includes an LED drive circuit 1, a mounting bracket 2, a rotating disc 6, a rotating disc drive system 7, a fixed bracket 8, a spectrometer 9, an optical fiber 10, Integrating sphere 11, computer control system 12; described LED driving circuit 1 and rotating disk 6 are respectively fixed on the installation bracket 2, and LED testing installation hole is set on rotating disk 6, and integrating sphere 11 is arranged at the corresponding position of LED testing installation hole , the light exit hole of the integrating sphere 11 is connected to one end of the optical fiber 10, and the other end of the optical fiber 10 is connected to the spectrometer 9; the rotating disk drive system 7 is fixed at the bottom of the rotating disk 6, and the rotating disk driving system 7 is fixed on the fixed br...

specific Embodiment approach 2

[0015] Specific implementation mode 2. This implementation mode is an application example of the on-board calibration light source LED luminous performance test device described in specific implementation mode 1:

[0016] combine figure 1 , the LED driving circuit 1 is an LED constant current driving board, and its driving current is 5mA, 10mA, 15mA, 20mA, 25mA, 30mA, 35mA, 40mA, 45mA, 50mA, 60mA, 85mA, 100mA; For the required current, each LED is powered by a constant current. combine figure 2 , the first LED test installation hole 3, the second LED test installation hole 4 and the third LED test installation hole 5 can be respectively installed Test mounting holes for cannonball LEDs and SMD LEDs for testing different shapes of LEDs. The rotating disc 6 is a rotatable disc with a diameter of 0.5m, and the LEDs to be tested are installed in the corresponding test installation holes, and the corresponding LEDs can only be installed in the same ring of installation holes f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com