Composite multiple dirt dispersion agent for oilfield flooding treatment and preparation method thereof

A scale inhibitor and dispersant, multi-technology, applied in water/sludge/sewage treatment, chemical instruments and methods, scale removal and water softening, etc. To solve the problem of single scale effect, it can achieve the effect of high-efficiency silica scale deposition, preventing silica scale deposition, and good scale inhibition and dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

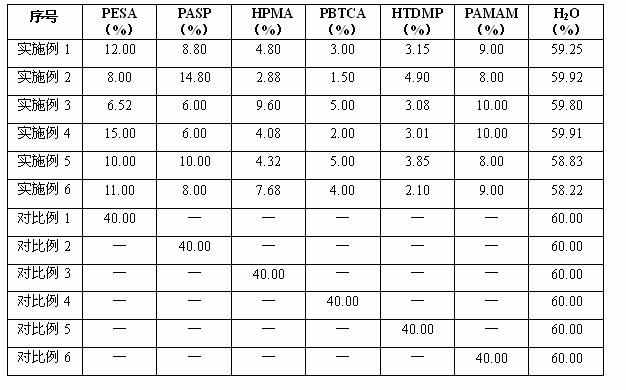

[0043] Example 1 Preparation of composite multi-element scale inhibitor and dispersant

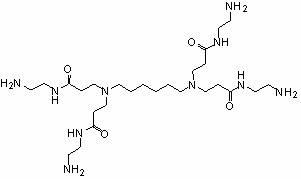

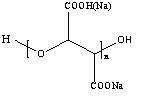

[0044] Prepare 100.00g of composite multi-component antiscaling and dispersing agent: mix 10.00g of polymaleic acid (HPMA) with a solid content of 48% and 7.00g of water and stir evenly, then add 30.00g of polyepoxysuccinic acid with a solid content of 40% Sodium (PESA) polyepoxysuccinic acid, stirred for 30 minutes, then added 9.00 g of hexapotassium hexamethylenediaminetetramethylphosphate (HTDMP) with a solid content of 35%, and stirred for another 30 minutes to obtain Agent A. Mix 6.00g of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) with a solid content of 50% and 7.00g of water and stir evenly, then add 22.00g of polyaspartate with a solid content of 40% Acid sodium (PASP), stirred for 30 minutes, then added 9.00 g of polyamidoamine (PAMAM) with hexamethylenediamine as the core, and stirred for another 30 minutes to obtain agent B. Mix agent A and agent B and stir for 30 minut...

Embodiment 2

[0048] Example 2: Preparation of composite multi-element scale inhibitor dispersant

[0049] Prepare 100.00g of composite multi-component antiscaling and dispersing agent: mix 6.00g of polymaleic acid (HPMA) with a solid content of 48% and 6.00g of water and stir evenly, then add 20.00g of polyepoxysuccinic acid with a solid content of 40% Sodium (PESA) polyepoxysuccinic acid, stirred for 30 minutes, then added 14.00 g of hexapotassium hexamethylenediaminetetramethylphosphate (HTDMP) with a solid content of 35%, and stirred for another 30 minutes to obtain Agent A. Mix 3.00g of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) with a solid content of 50% and 6.00g of water and stir evenly, then add 37.00g of polyaspartate with a solid content of 40% Acid sodium (PASP), stirred for 30 minutes, then added 8.00 g of polyamidoamine (PAMAM) with hexamethylenediamine as the core, and stirred for another 30 minutes to obtain B agent. Mix agent A and agent B and stir for 30 minutes ...

Embodiment 3

[0053] Example 3: Preparation of composite multi-element scale inhibitor dispersant

[0054] Prepare 100.00g of composite multi-component antiscaling and dispersing agent: mix 20.00g of polymaleic acid (HPMA) with a solid content of 48% and 9.90g of water and stir evenly, then add 16.30g of polyepoxysuccinic acid with a solid content of 40% Sodium (PESA) polyepoxysuccinic acid, stirred for 30 minutes, then added 8.80 g of hexapotassium hexamethylenediaminetetramethylphosphate (HTDMP) with a solid content of 35%, and stirred for another 30 minutes to obtain Agent A. Mix 10.00g of 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) with a solid content of 50% and 10.00g of water and stir evenly, then add 15.00g of polyaspartate with a solid content of 40% Acid sodium (PASP), stirred for 30 minutes, then added 10.00 g of polyamidoamine (PAMAM) with hexamethylenediamine as the core, and stirred for another 30 minutes to obtain B agent. Mix agent A and agent B and stir for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com